Precision Plastic Injection Moulding

Need A Top-Quality Precision Injection Moulding Company?

Make Sure You Contact Us!

At Bosworth Plastics, we provide industry-leading precision injection moulding services that meet the strict quality control standards necessary to create market-ready products. Our expertise in precision moulding allows us to produce parts and components that are not only accurate and reliable but also suitable for a variety of applications, ranging from medical devices to automotive components.

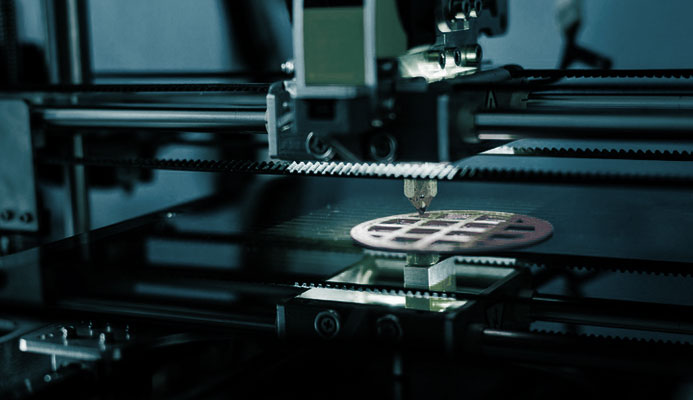

While traditional injection moulding is commonly used for mass-producing plastic parts, precision injection moulding elevates this process. By emphasising tighter tolerances, better material control, and advanced equipment, we can create highly accurate, consistent, and complex parts that meet your exact specifications.

What A Precision Injection Moulding Company Does

Precision injection moulding is a specialised technique used to create intricate plastic parts with exceptionally tight tolerances and high repeatability.

While standard injection moulding is typically adequate for less critical components, precision injection moulding is essential when a part’s dimensions, structural integrity, and overall quality must meet stringent specifications.

This process is particularly crucial in industries such as medical devices, aerospace, automotive, electronics, and telecommunications, where even the smallest deviation can lead to product failure or performance issues.

Several key factors define the precision injection moulding process, including:

- Tight Tolerances: Precision moulding aims to produce parts with tolerances as tight as ±0.001 inches or even smaller, ensuring every component meets the required specifications.

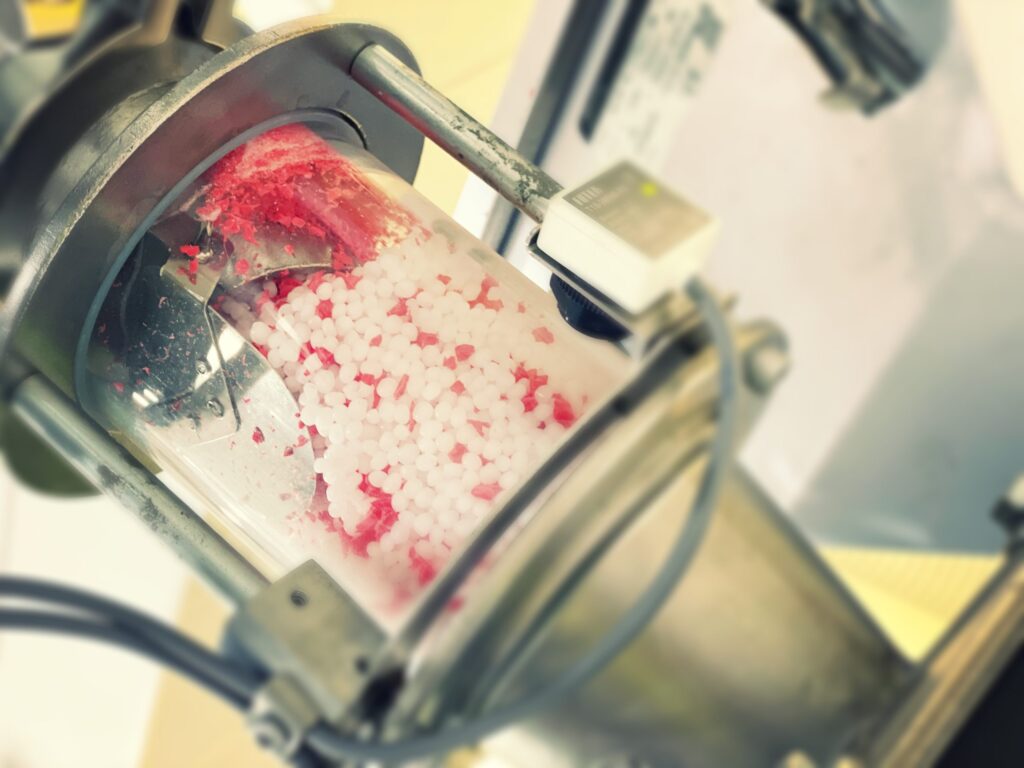

- High-Quality Materials: The materials used in precision moulding must have consistent properties, such as viscosity and shrinkage, to ensure the final product meets the desired standards.

- Controlled Environment: Often, precision moulding requires a cleanroom or controlled environment to prevent contamination and other factors that could compromise the accuracy of the moulded parts.

- Advanced Moulding Machines: High-precision machinery that can control pressure, temperature, and injection speed with exceptional accuracy is essential for creating precision parts.

At Bosworth Plastics, we’ve invested in the latest technology and processes to ensure we flawlessly meet the demands of precision injection moulding, delivering parts that comply with even the strictest tolerances and quality standards.

How Precision Plastic Injection Moulding Differs From Standard Injection Moulding

While standard and precision injection moulding both operate on the same basic principles, there are significant differences that set precision moulding apart.

- Tolerance And Accuracy

Standard injection moulding is generally used for parts that can tolerate a bit more variation, with tolerances ranging from ±0.005 inches to ±0.020 inches. This level of precision is usually sufficient for everyday consumer products and non-critical components.

In contrast, precision injection moulding is essential when parts need much tighter tolerances, often within ±0.001 inches or even smaller. This high level of accuracy is crucial for industries like medical devices or aerospace, where even minor deviations can lead to serious product failures.

Precision moulding excels at creating intricate, small parts that must fit together perfectly or meet strict performance standards.

At Bosworth Plastics, our precision moulding capabilities allow us to meet the tight tolerances required in specialised fields such as healthcare, electronics, and automotive, ensuring every component is accurate and consistent.

- Material Selection And Control

In standard injection moulding, material choices are often influenced by factors like cost, durability, and ease of manufacturing. While these considerations are essential, the properties of the material (like shrinkage and viscosity) don’t need to be monitored as closely as in precision moulding.

By contrast, precision injection moulding requires a more rigorous approach to material control. We must carefully monitor and adjust the flow properties, shrinkage rate, and temperature resistance of the materials to ensure the final product meets exact specifications.

For instance, certain medical devices or high-performance automotive components may demand materials that offer greater structural integrity or heat resistance.

At Bosworth Plastics, we collaborate closely with our clients to select the most suitable materials for precision moulding projects, while using advanced monitoring systems to ensure consistency and accuracy in every batch.

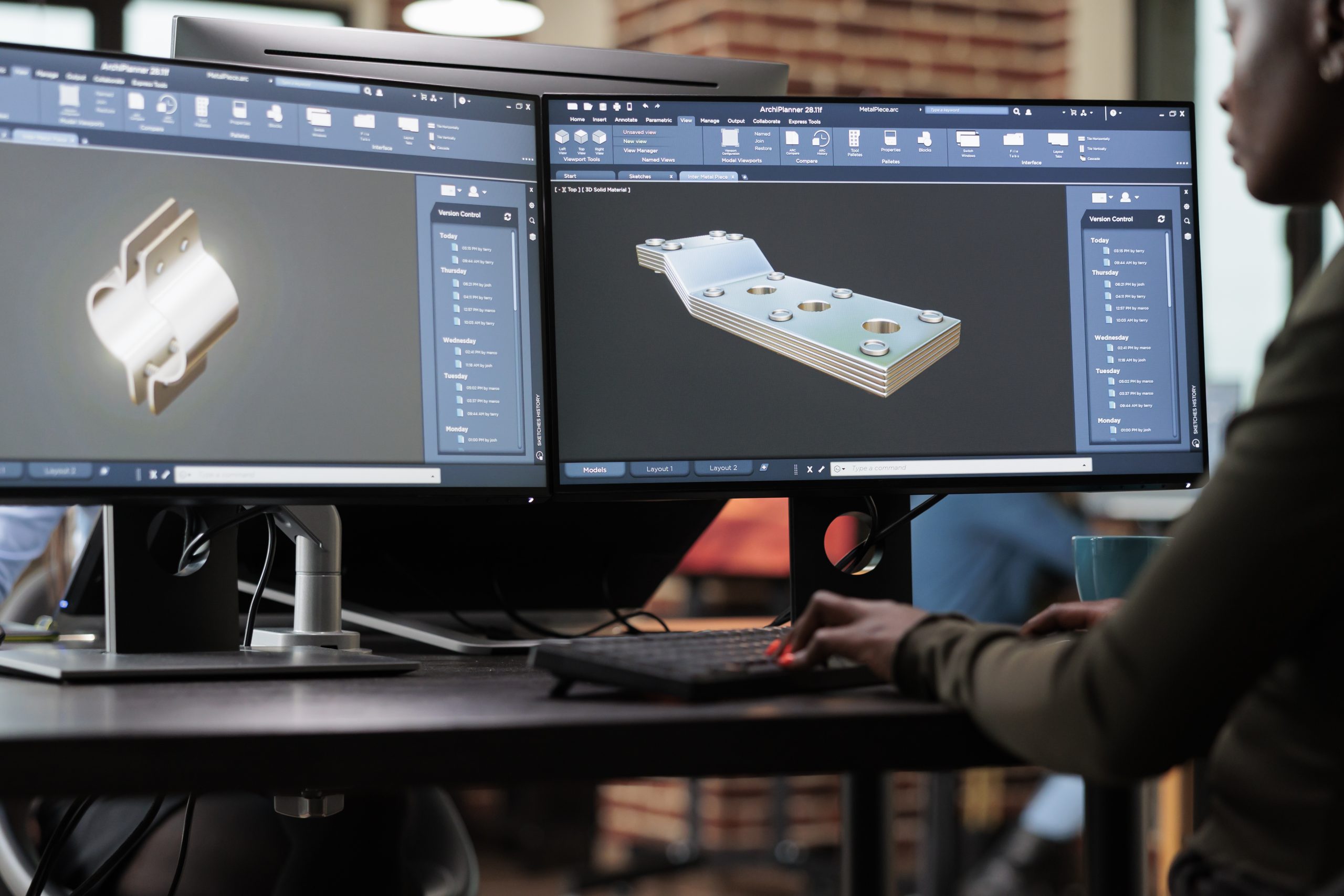

- Moulding Equipment And Technology

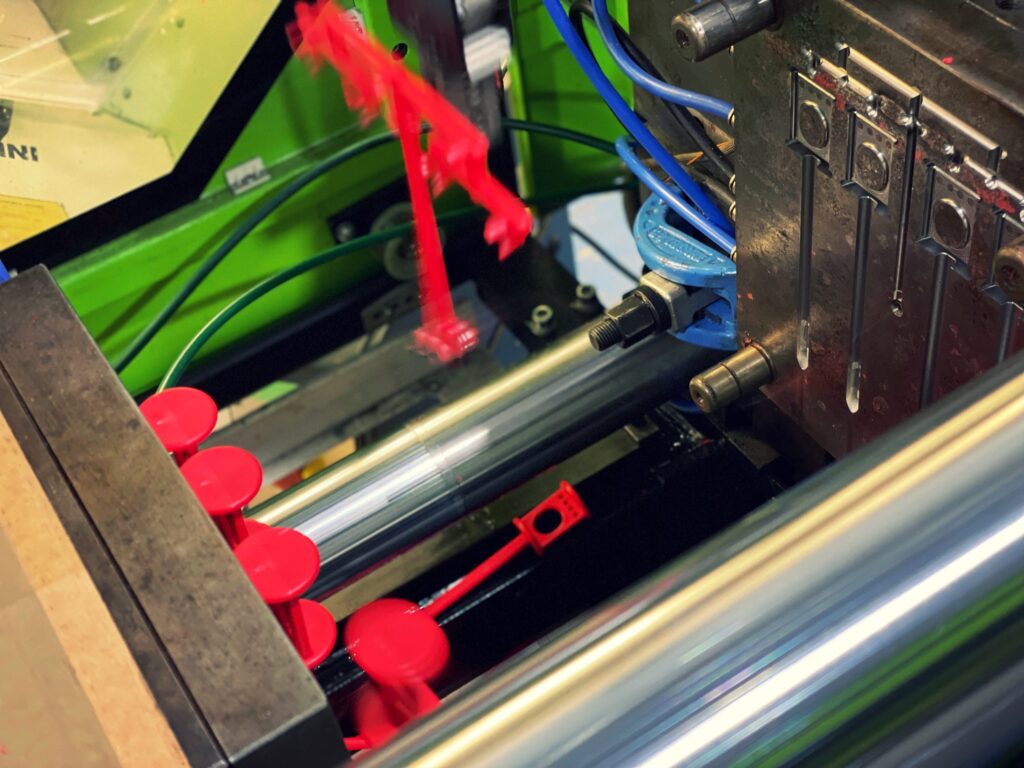

Both standard and precision moulding utilise injection machines, but precision moulding demands more advanced and high-precision equipment. Standard moulding machines often lack the level of control necessary to maintain tight tolerances, especially when dealing with complex shapes or small parts.

On the other hand, precision injection moulding machines are equipped with sophisticated controls that allow for precise management of injection speed, pressure, and temperature. These machines can make micro-adjustments during the moulding process to ensure each part is produced to exact specifications.

At Bosworth Plastics, we use state-of-the-art precision moulding machines equipped with the latest control systems, guaranteeing accuracy and repeatability. Our machines are capable of producing complex parts with tight tolerances, regardless of size or complexity.

- Production Environment

While standard injection moulding can be carried out in general manufacturing settings, precision injection moulding often requires a more controlled environment.

For instance, parts used in medical devices or aerospace components must be manufactured in cleanrooms or environments with minimal contamination. This ensures the parts meet the necessary safety and performance standards.

At Bosworth Plastics, we are fully equipped to handle precision moulding in cleanroom environments, providing an additional level of assurance for clients in the healthcare and aerospace industries.

The Applications Of Precision Plastic Injection Moulding

Precision injection moulding is essential in various industries that demand high-performance and reliable components.

At Bosworth Plastics, we cater to several key sectors, including:

1. Medical And Healthcare

The medical industry often requires precision injection moulding due to the complex designs of its devices and the vital role these products play in patient care.

For example, items like surgical instruments, drug delivery systems, and diagnostic equipment must adhere to stringent regulatory standards and be free from defects.

Our precision moulding processes guarantee that these components are manufactured with the utmost accuracy, ensuring safety, functionality, and ease of use.

We specialise in producing medical-grade parts that comply with all relevant UK regulations, and our cleanroom facilities ensure that every component is made in a contamination-free environment.

2. Automotive

The automotive sector relies heavily on precision injection moulding for components that demand tight tolerances and exceptional performance. From engine parts to interior fittings, precision moulding enables manufacturers to create durable, lightweight components that enhance vehicle performance and fuel efficiency.

At Bosworth Plastics, we collaborate with automotive manufacturers to produce high-quality, precision-moulded parts that meet the industry’s rigorous specifications. We utilise materials that resist heat, wear, and chemical exposure, ensuring the longevity and reliability of the components we supply.

3. Electronics

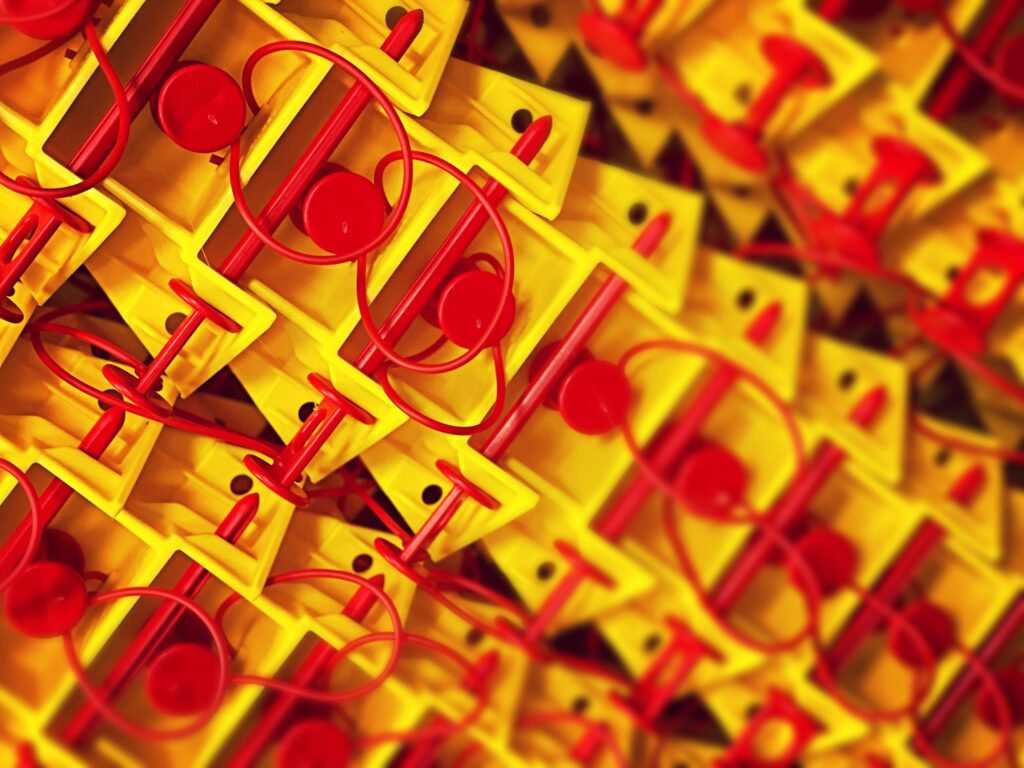

In the electronics sector, precision injection moulding is vital for creating small, intricate parts like connectors, housings, and circuit board components. These components need to be produced with exact tolerances to ensure they fit together seamlessly and function correctly.

At Bosworth Plastics, we specialise in crafting precision-moulded components for the electronics industry, using materials that offer excellent electrical insulation and thermal resistance.

4. Aerospace

Aerospace components must adhere to extremely high safety and performance standards. Precision injection moulding is crucial for producing parts that are lightweight, durable, and able to withstand extreme temperatures and pressures.

With our experience in the aerospace industry, Bosworth Plastics ensures that each component meets the stringent regulatory requirements necessary for this demanding sector.

Why Choose Bosworth Plastics To Be Your Precision Injection Moulding Company?

At Bosworth Plastics, we take pride in delivering top-notch precision injection moulding services to our clients. Here’s why businesses from many industries choose us for their precision moulding requirements:

- Advanced Technology: We utilise state-of-the-art moulding machines that are fitted with the latest control systems, guaranteeing both accuracy and consistency in every product.

- Material Expertise: Our team works with a diverse selection of materials, ranging from standard plastics to high-performance polymers, ensuring we can cater to the unique needs of each project.

- Cleanroom Manufacturing: For sectors like medical and aerospace, we offer cleanroom manufacturing capabilities, providing a contamination-free environment for producing critical components.

- Experienced Team: Our talented team of designers, engineers, and project managers brings years of experience in precision injection moulding, allowing us to confidently tackle even the most complex projects.

- Quality Assurance: We have rigorous quality control and assurance processes in place, ensuring that every part we produce meets the highest standards of quality and precision.

About Us

Bosworth Plastics is your reliable partner for precision injection moulding services.

Whether you require high-performance components for the medical, automotive, electronics, or aerospace sectors, we have the expertise, technology, and dedication to deliver products that meet your exact requirements. Our precision moulding capabilities guarantee that each part is crafted with exceptional accuracy, reliability, and quality.

When you choose Bosworth Plastics, you can trust that your products are in capable hands, guiding you from initial concept all the way to completion!

Plastic Injection Moulded Product Specialist