Concept Development

Concept Development

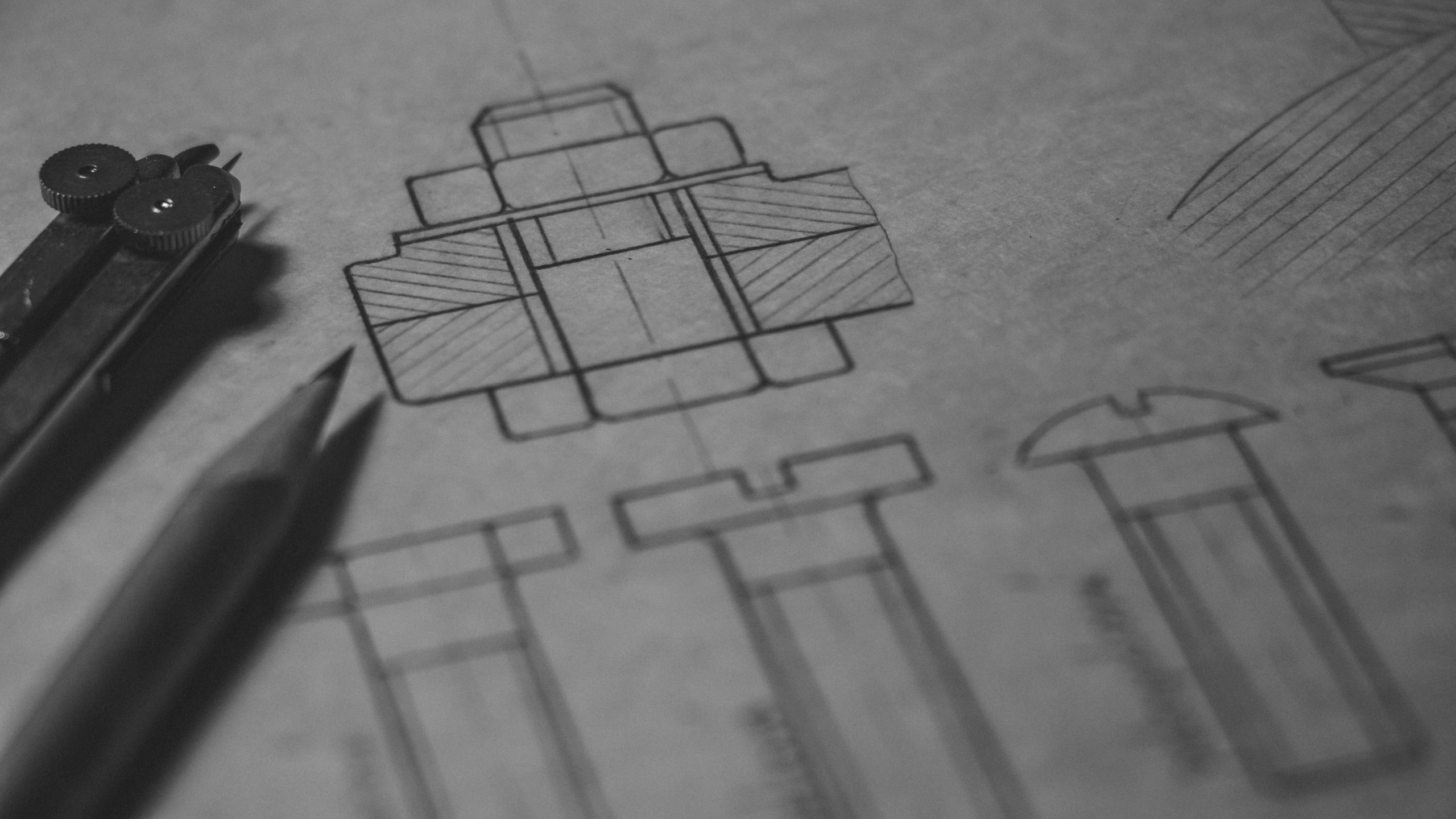

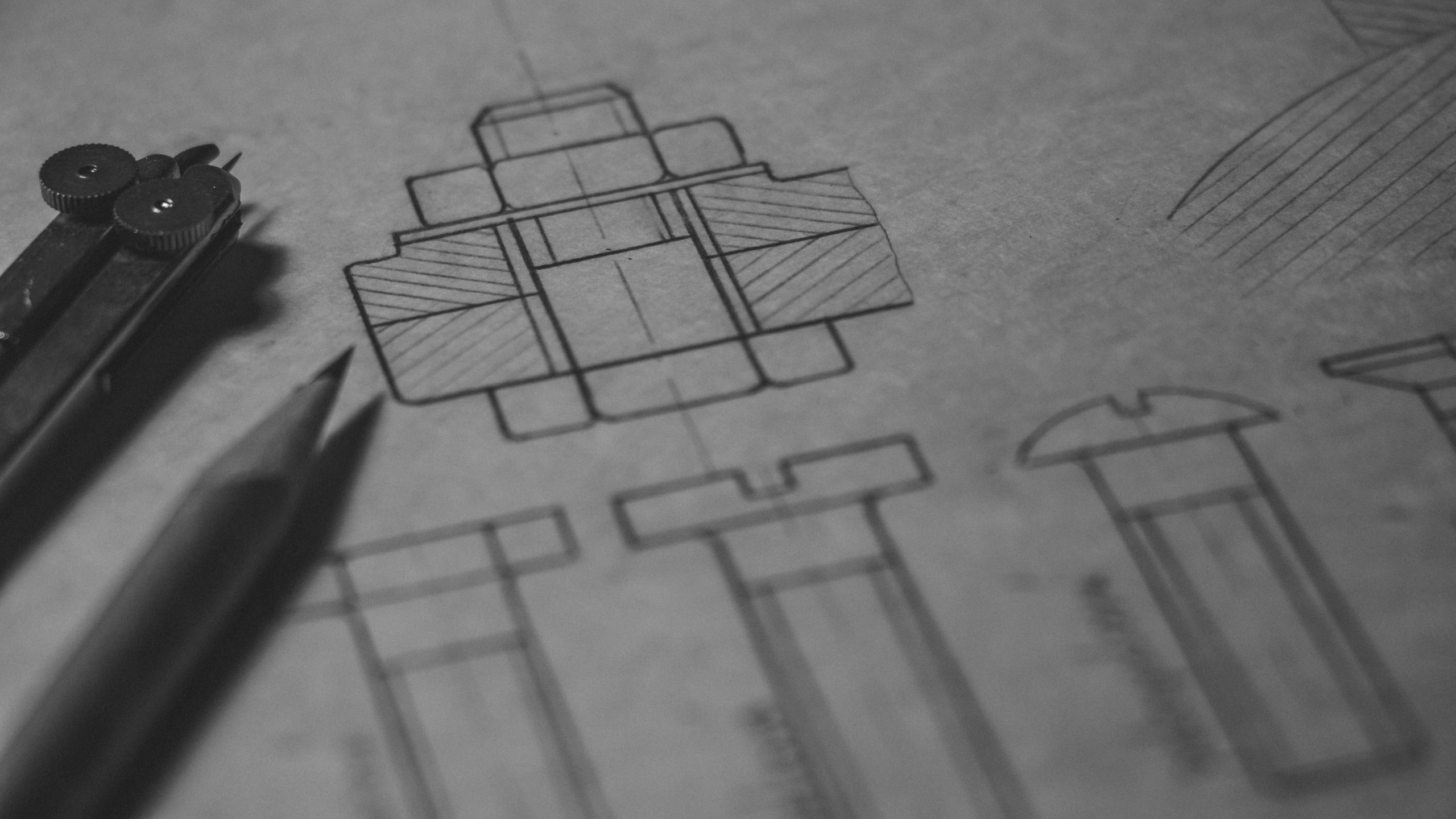

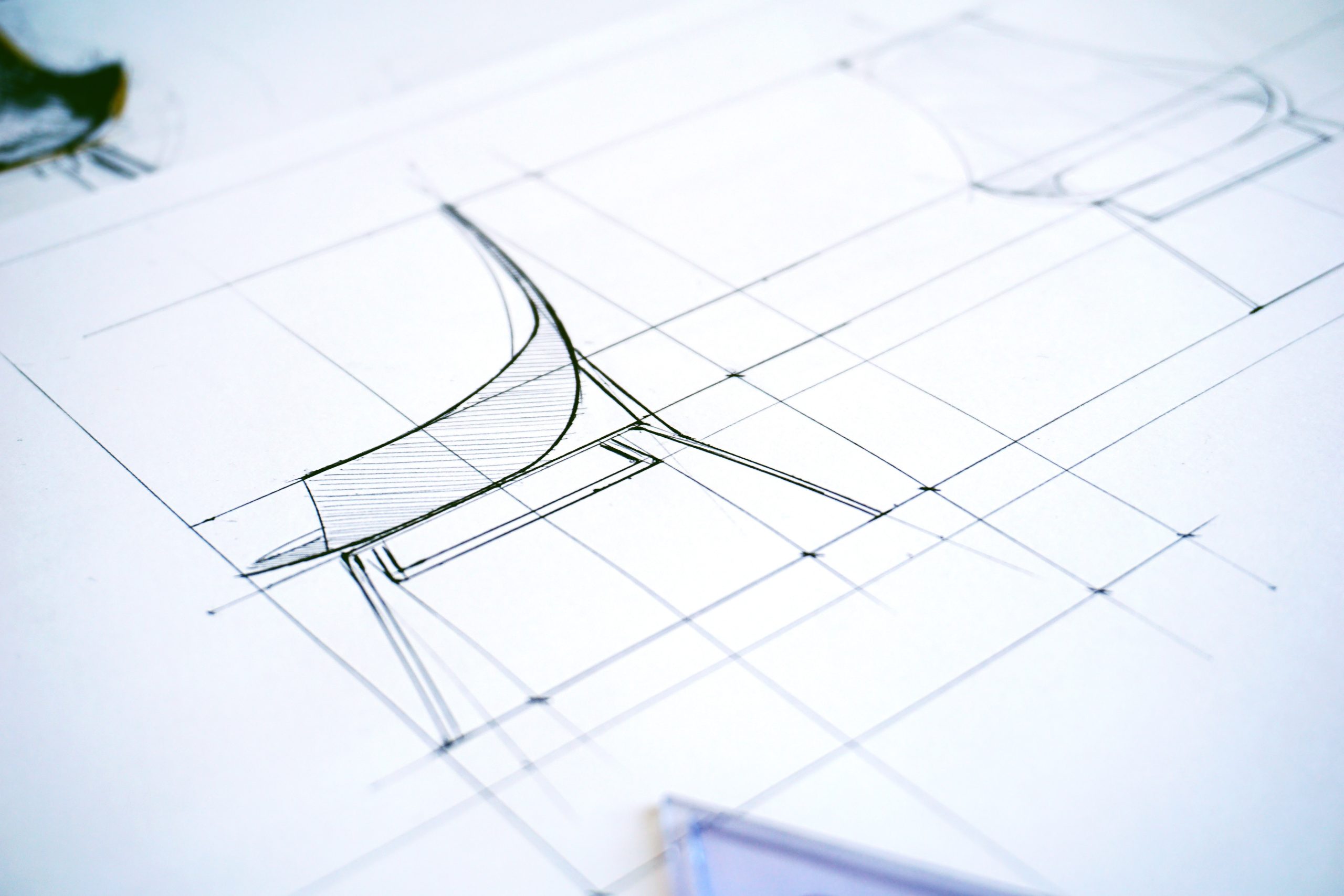

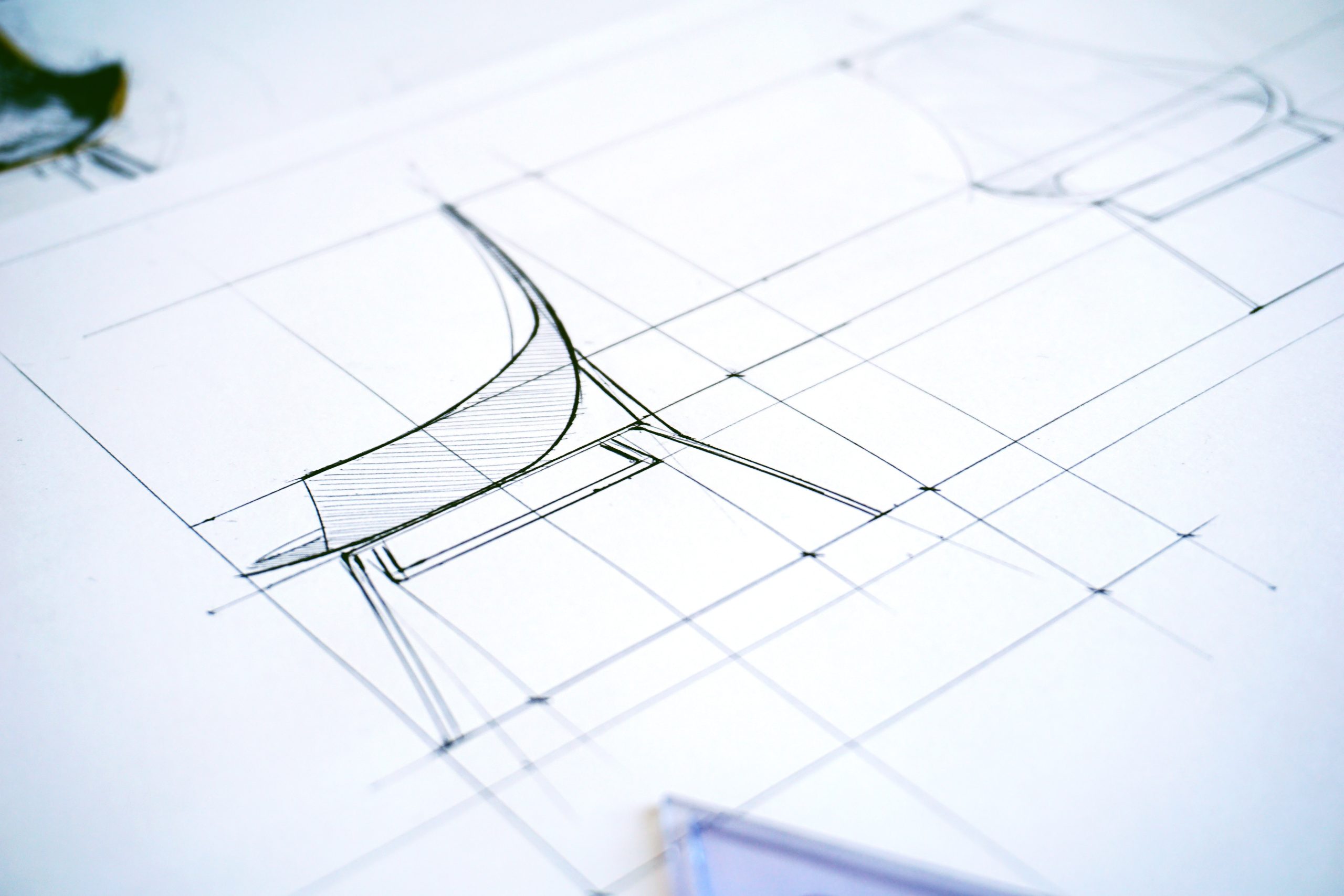

As part of our design service we can offer a concept design stage; it sets the agenda and delivers ‘the vision’. We start the design and development process with quick hand drawn sketching which explore form, function, colour and ergonomic interaction; creating a flow of ideas to instantly evaluate against one another.

In the realm of design, the concept development stage serves as the compass guiding groundbreaking ideas to fruition. At Bosworth Plastics, a prominent player in the UK Manufacturing landscape, we delve into the heart of this phase, unveiling its technical intricacies and creative essence.

Concept Design Stage

Beyond ideation lies the concept design stage—a platform for visionary ideas to take root. In our commitment to UK Manufacturing excellence, Bosworth Plastics recognises this phase’s pivotal role. It’s here that we lay the groundwork for transformative projects, crystallising ‘the vision’ that propels designs from concept to reality.

Concept Development

Hand-drawn sketches play a crucial role, merging the worlds of art and functionality. These sketches form the bridge between aesthetics and practicality. In each stroke, design elements, colour palettes, and ergonomic considerations meld, shaping an interface that resonates with user experience.

Concept development thrives on dynamism. At Bosworth Plastics, we engage in a process of real-time evaluation, allowing ideas to flow organically. Every sketch represents a potential direction, rapidly assessed against others. This process ensures that only the most viable concepts are pursued, refining them on the go.

Concept Development

Hand-drawn sketches play a crucial role, merging the worlds of art and functionality. These sketches form the bridge between aesthetics and practicality. In each stroke, design elements, colour palettes, and ergonomic considerations meld, shaping an interface that resonates with user experience.

Concept development thrives on dynamism. At Bosworth Plastics, we engage in a process of real-time evaluation, allowing ideas to flow organically. Every sketch represents a potential direction, rapidly assessed against others. This process ensures that only the most viable concepts are pursued, refining them on the go.

Concept Design Stage

Beyond ideation lies the concept design stage—a platform for visionary ideas to take root. In our commitment to UK Manufacturing excellence, Bosworth Plastics recognises this phase’s pivotal role. It’s here that we lay the groundwork for transformative projects, crystallising ‘the vision’ that propels designs from concept to reality.

Elevating through Design for Manufacture (DFM)

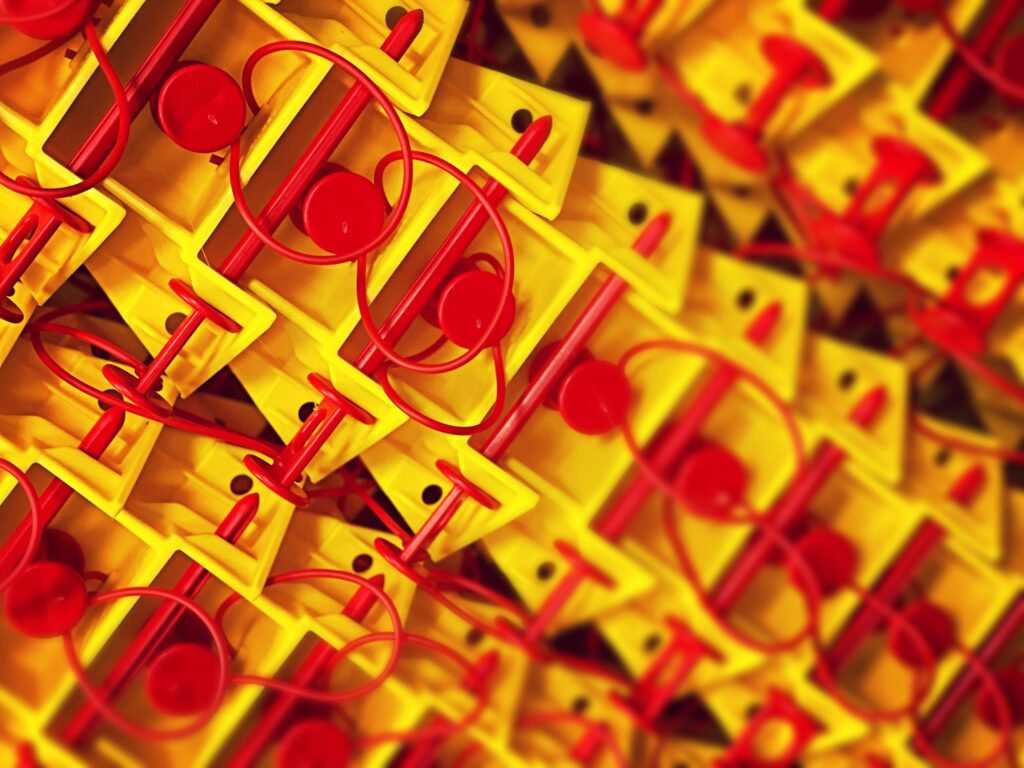

We are dedicated to crafting designs that surpass aesthetics. Rooted in the principle of Design for Manufacture (DFM), our approach ensures that creativity harmonises with functionality. This approach results in designs that are not only visually pleasing but seamlessly executable.

Beyond the technicalities, personalisation is key. Our designs are tailored to your needs, embracing your aspirations and challenges. By understanding your unique context, Bosworth Plastics delivers designs that reflect not only innovation but also your individuality.

Elevating through Design for Manufacture (DFM)

We are dedicated to crafting designs that surpass aesthetics. Rooted in the principle of Design for Manufacture (DFM), our approach ensures that creativity harmonises with functionality. This approach results in designs that are not only visually pleasing but seamlessly executable.

Beyond the technicalities, personalisation is key. Our designs are tailored to your needs, embracing your aspirations and challenges. By understanding your unique context, Bosworth Plastics delivers designs that reflect not only innovation but also your individuality.

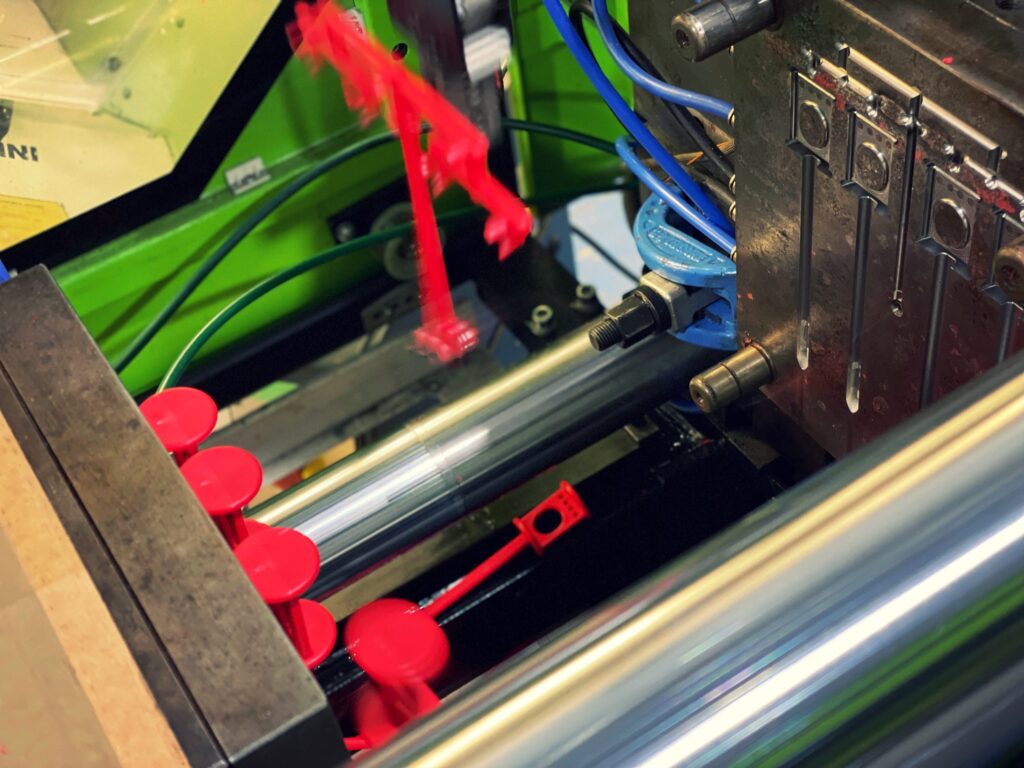

Plastic injection moulded product specialist