High Precision Plastic Injection Molding

Need High Precision Injection Molding?

Make Sure You Contact Us!

At Bosworth Plastics, we take pride in offering industry-leading high precision injection molding services that adhere to strict quality controls, ensuring that our products are not only market-ready but also meet the highest possible standards.

Our expertise in precision molding techniques enables us to produce parts and components that are dependable and precisely crafted for many applications, including medical devices, automotive parts, and aerospace fixtures.

While traditional injection molding is commonly used for large-scale production of plastic components, we elevate the process through precision injection molding. By emphasising tighter tolerances, better material management, and advanced equipment, we can create parts that are incredibly accurate, consistent, and complex, all while meeting specific requirements.

What A High Precision Plastic Injection Molding Company Does

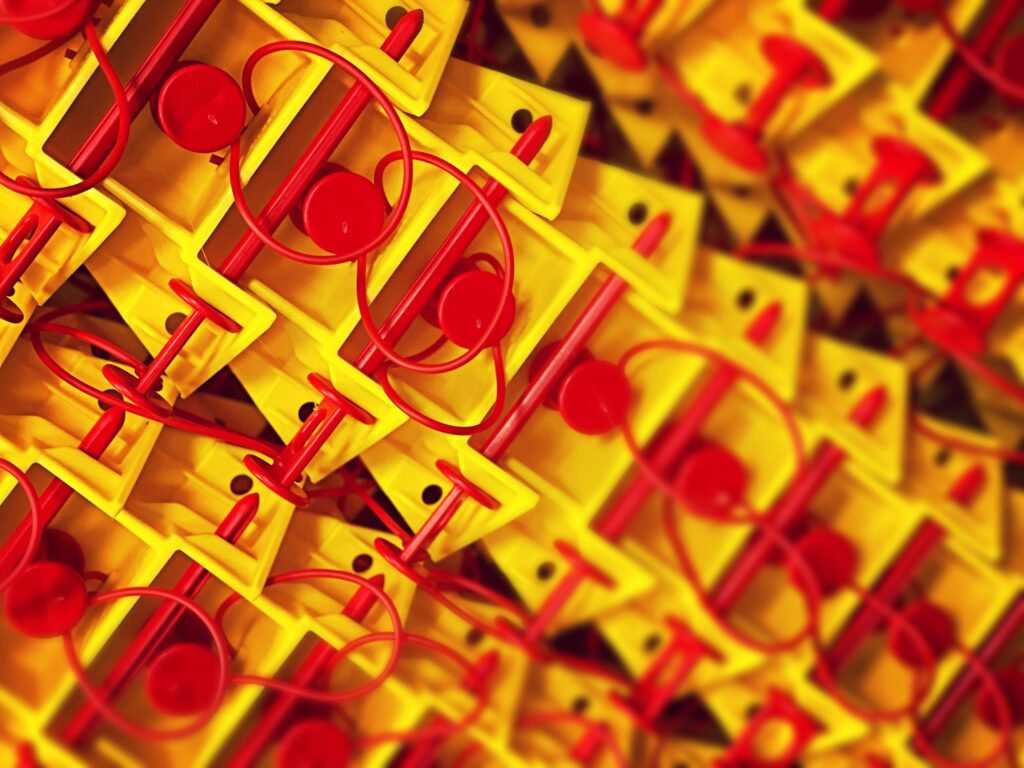

Precision injection molding is a specialised technique designed to create complex plastic parts with extremely tight tolerances and a high level of consistency.

While standard injection molding works well for less critical components, precision injection molding is essential when parts must meet strict specifications for dimensions, structural integrity, and overall quality.

This process is essential for manufacturing products for the medical, aerospace, automotive and electronics industries, among other sectors, where even minor inaccuracies can lead to product failures or performance problems.

Here are some key benefits of precision injection molding:

- Tight Tolerances: This method aims to produce parts with tolerances as tight as ±0.001 inches or even smaller, ensuring that each component meets the exact requirements.

- Advanced Molding Machines: To achieve the necessary precision, specialised machinery is required that can carefully control pressure, temperature, and injection speed.

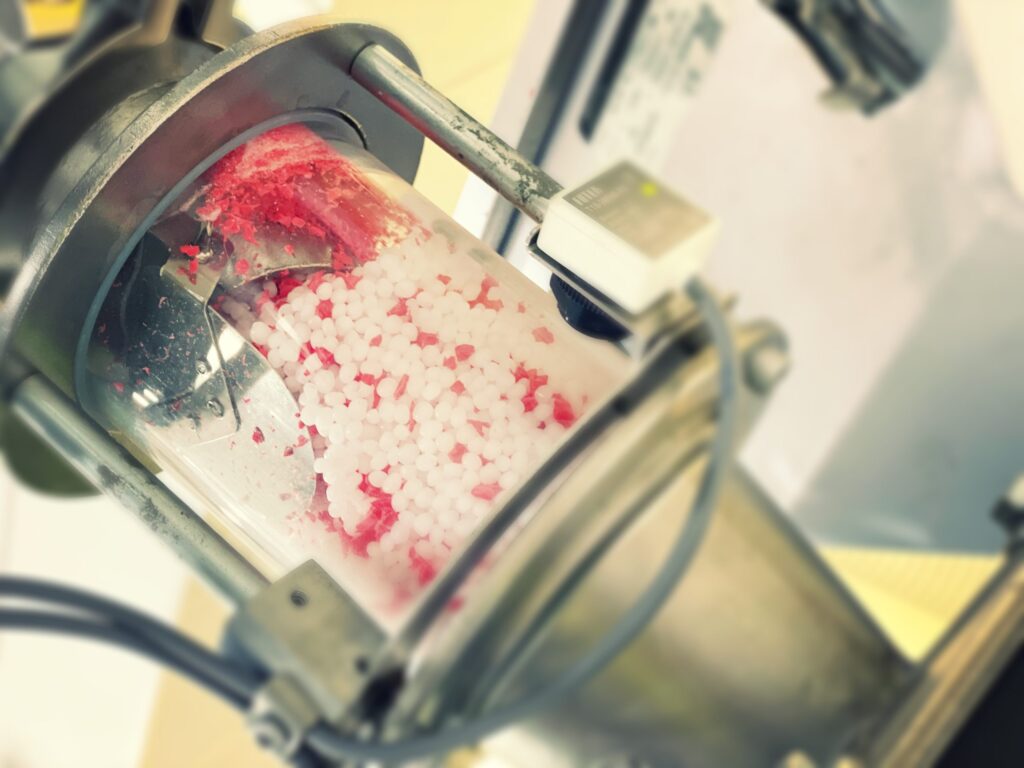

- High-Quality Materials: The materials used must have consistent properties, such as viscosity and shrinkage, to ensure that the final product meets high standards.

- Controlled Environment: Often, a cleanroom or controlled setting is needed to prevent contamination and other factors that could affect the accuracy of the molded

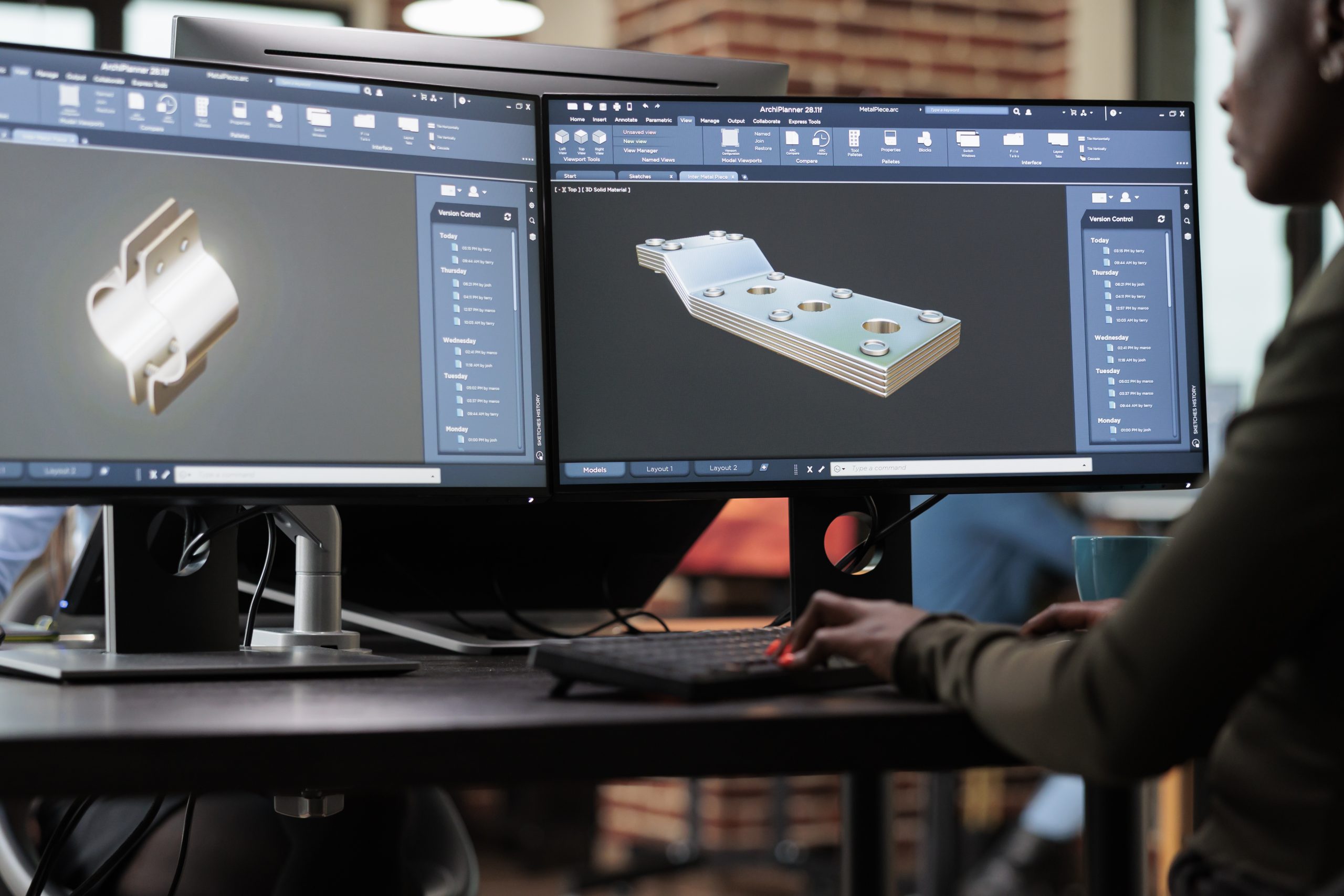

At Bosworth Plastics, we’ve invested in using cutting-edge technology and processes to meet the rigorous demands of precision injection molding, allowing us to produce parts that meet even the highest tolerances and quality standards.

How High Precision Injection Molding Differs From Standard Injection Molding

While standard and precision injection molding share some basic principles, there are significant differences that make precision molding unique.

- Tolerance And Accuracy

Standard injection molding is typically used for parts that don’t need extremely tight tolerances, usually falling between ±0.005 inches to ±0.020 inches. This level of precision works well for everyday consumer products and less critical components.

In contrast, precision injection molding is necessary for parts that require much tighter tolerances, often within ±0.001 inches or even smaller. This high level of accuracy is crucial in fields like medical devices or aerospace, where even slight variations can lead to product failures.

Precision molding excels at creating intricate, small components that must fit perfectly and meet strict performance standards. At Bosworth Plastics, we specialise in precision molding, enabling us to meet the exacting tolerances needed in specialised industries such as healthcare, electronics, and automotive.

- Material Selection And Control

In standard injection molding, material choice is often influenced by cost, durability, and ease of manufacturing. While these factors are important, the properties of the materials (like shrinkage and viscosity) don’t require as much stringent control as they do in precision molding.

On the other hand, precision injection molding demands meticulous oversight of material characteristics. Factors like flow properties, shrinkage rates, and temperature resistance must be carefully monitored and adjusted to ensure that the final product meets exact specifications. For example, certain medical devices or high-performance automotive parts may need particular materials to ensure greater structural integrity or heat resistance.

At Bosworth Plastics, we collaborate closely with our clients to identify the best materials for their precision molding projects and utilise advanced monitoring systems to manage material properties during the injection process, guaranteeing consistency and accuracy in every batch.

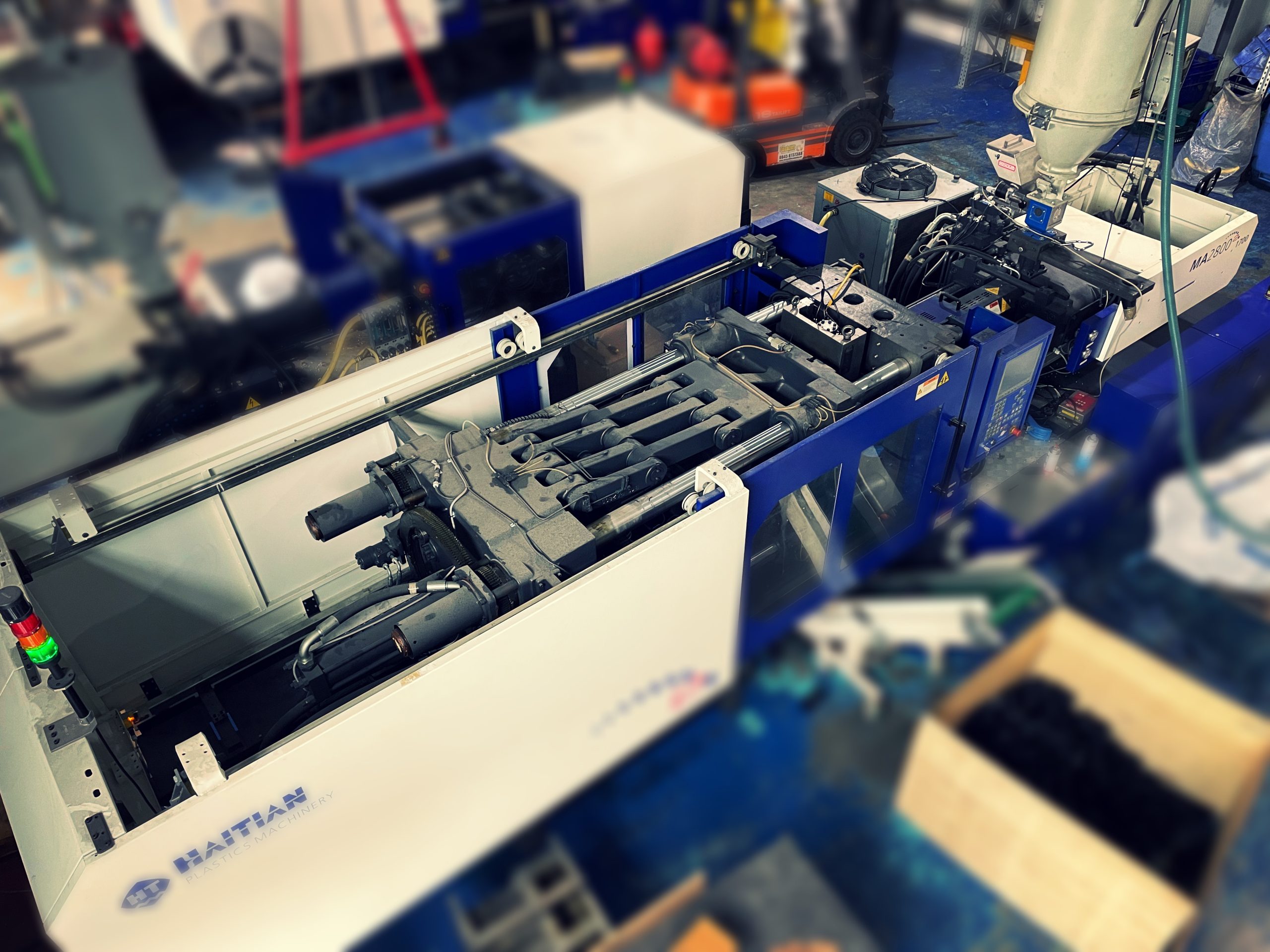

- Molding Equipment And Technology

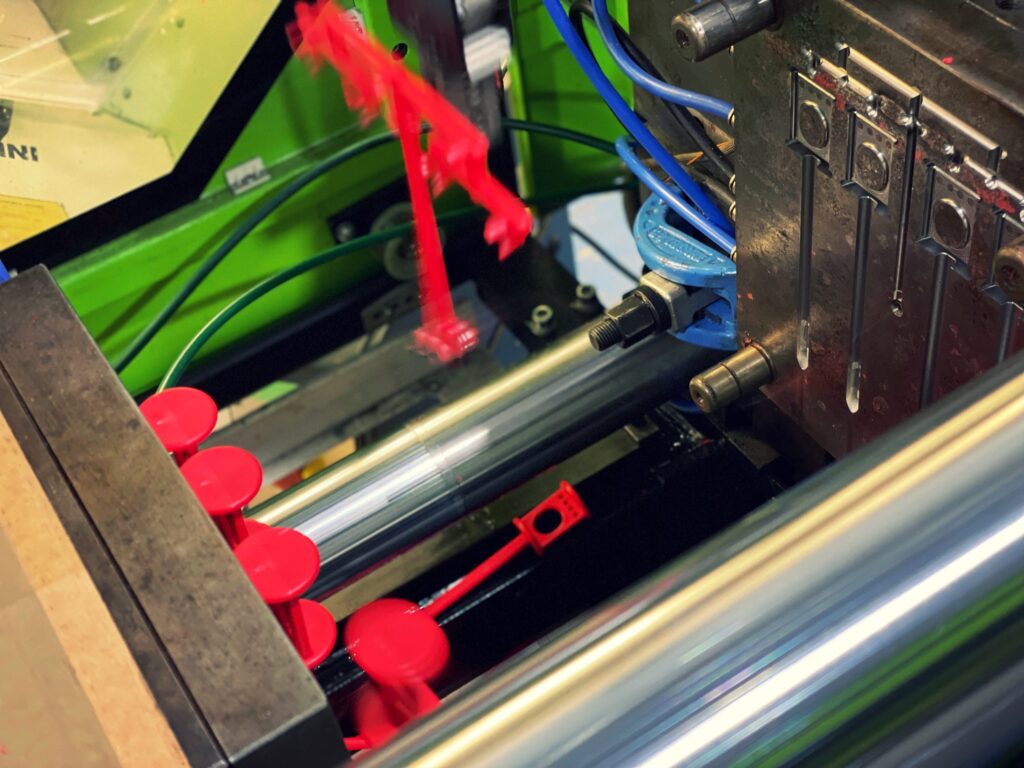

Both standard and precision molding use injection machines, but precision molding relies on more advanced and high-precision equipment. Standard molding machines often lack the control necessary to maintain tight tolerances, especially for complex shapes or small parts.

Precision injection molding machines, however, use sophisticated controls that allow for precise management of injection speed, pressure, and temperature. These machines can make micro-adjustments during the molding process, ensuring that every part is produced to the exact specifications.

At Bosworth Plastics, we harness cutting-edge precision molding machines fitted with the latest control systems to ensure accuracy and repeatability, capable of producing complex parts with tight tolerances, regardless of size or complexity.

- Production Environment

Standard injection molding can typically be carried out in regular manufacturing settings, but precision injection molding often requires a more controlled environment. For example, components intended for medical devices or aerospace applications must be manufactured in cleanrooms or spaces with minimal contamination to meet stringent safety and performance standards.

Bosworth Plastics is fully equipped to manage precision molding in cleanroom environments, offering added reassurance to our clients in the healthcare, aerospace, and other sectors.

The Applications Of High Precision Injection Molding

Precision injection molding plays a vital role in a variety of industries that demand high-quality, reliable components. At Bosworth Plastics, we cater to several sectors, including:

- Medical And Healthcare

In the medical field, devices and components often have intricate designs and are critical to patient care, which is why they rely on precision injection molding.

Surgical instruments, drug delivery systems, and diagnostic equipment all need to meet strict regulatory standards and be free from defects. Our precision molding guarantees that these parts are crafted with the utmost accuracy, ensuring they are safe, functional, and user-friendly.

At Bosworth Plastics, we focus on creating medical-grade components that comply with all relevant UK regulations, and our cleanroom manufacturing capabilities help us maintain a contamination-free production environment.

- Automotive

The automotive industry depends on precision injection molding for parts that require tight tolerances and high performance. Whether it’s engine components or interior parts, precision molding enables manufacturers to create durable, lightweight pieces that enhance vehicle performance and fuel efficiency.

We offer automotive manufacturers high-quality, precision-molded parts that meet their rigorous specifications, using materials that are designed to withstand heat, wear, and chemical exposure, ensuring the durability and reliability of our products.

- Electronics

In the electronics sector, precision injection molding is essential for producing small, complex parts like connectors, housings, and circuit board components. These pieces must be manufactured to exact specifications to ensure proper fit and functionality.

At Bosworth Plastics, we specialise in crafting precision-molded components for the electronics industry, utilising materials that provide excellent electrical insulation and thermal resistance.

- Aerospace

Aerospace components are held to exceptionally high safety and performance standards. Precision injection molding is crucial for producing parts that are lightweight, durable, and able to withstand extreme temperatures and pressures.

At Bosworth Plastics, we have the expertise to create precision-molded components for the aerospace industry, ensuring that each part meets the stringent regulatory requirements of this critical sector.

Why Choose Us To Be Your High Precision Plastic Injection Molding Company?

At Bosworth Plastics, we take pride in delivering exceptional precision injection molding services for all our clients.

Here’s what sets us apart and why businesses from various industries rely on us for their molding needs:

- State-of-the-Art Technology: We utilise advanced precision molding machines that come with the latest control systems, guaranteeing accuracy and consistency in every batch.

- Material Knowledge: Our expertise spans a broad spectrum of materials, from standard plastics to high-performance polymers, enabling us to cater to the unique requirements of each project.

- Cleanroom Manufacturing: For sectors like medical and aerospace, we provide cleanroom manufacturing capabilities to ensure that all components are created in a contamination-free setting.

- Experienced Team: Our skilled team of designers, engineers, and project managers has extensive experience in precision injection molding, allowing us to tackle even the most intricate projects with assurance.

- Commitment To Quality: We enforce rigorous quality control measures to ensure that every part we produce meets the highest standards of quality and precision.

About Us

At Bosworth Plastics, we’re proud to be your go-to partner for precision injection molding. Whether you’re in the medical, automotive, electronics, or aerospace sectors – or anything else – we have the skills, technology, and dedication to create parts that meet your specific needs, as our precision molding services ensure that every component is made with the utmost accuracy, reliability, and quality.

When you choose Bosworth Plastics, you can rest easy knowing your products are handled by experts every step of the way—from the initial concept all the way to completion!

Contact Us If You Need Top-Quality High Precision Injection Molding!

Contact Us If You Need Top-Quality High Precision Plastic Injection Molding!

Plastic Injection Moulded Product Specialist