Custom Injection Moulding

Need Top-Quality Custom Plastic Injection Moulding?

Look No Further Than Bosworth Plastics!

At Bosworth Plastics, we’re proud to be leaders in delivering custom plastic injection moulding services to discerning British businesses.

We continuously innovate our processes, embracing the latest advancements in CAD, CAM, and automation. This proactive mindset allows us to deliver quick turnaround times, lower costs, and top-notch products to our valued customers.

Our commitment to innovation goes beyond technology; we invest in extensive research and development. By collaborating with industry experts, we harness cutting-edge techniques that foster growth and learning throughout our organisation.

As a result, our clients benefit from not only exceptional service but also impressive results that constantly exceed their expectations!

What Is Custom Plastic Injection Moulding?

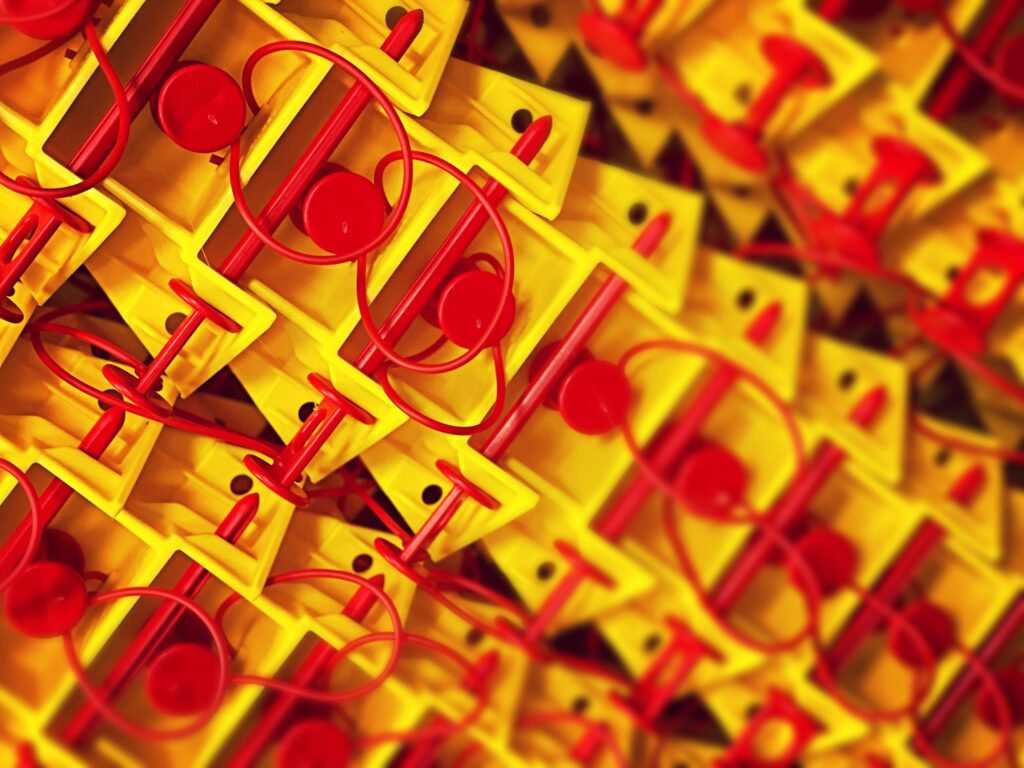

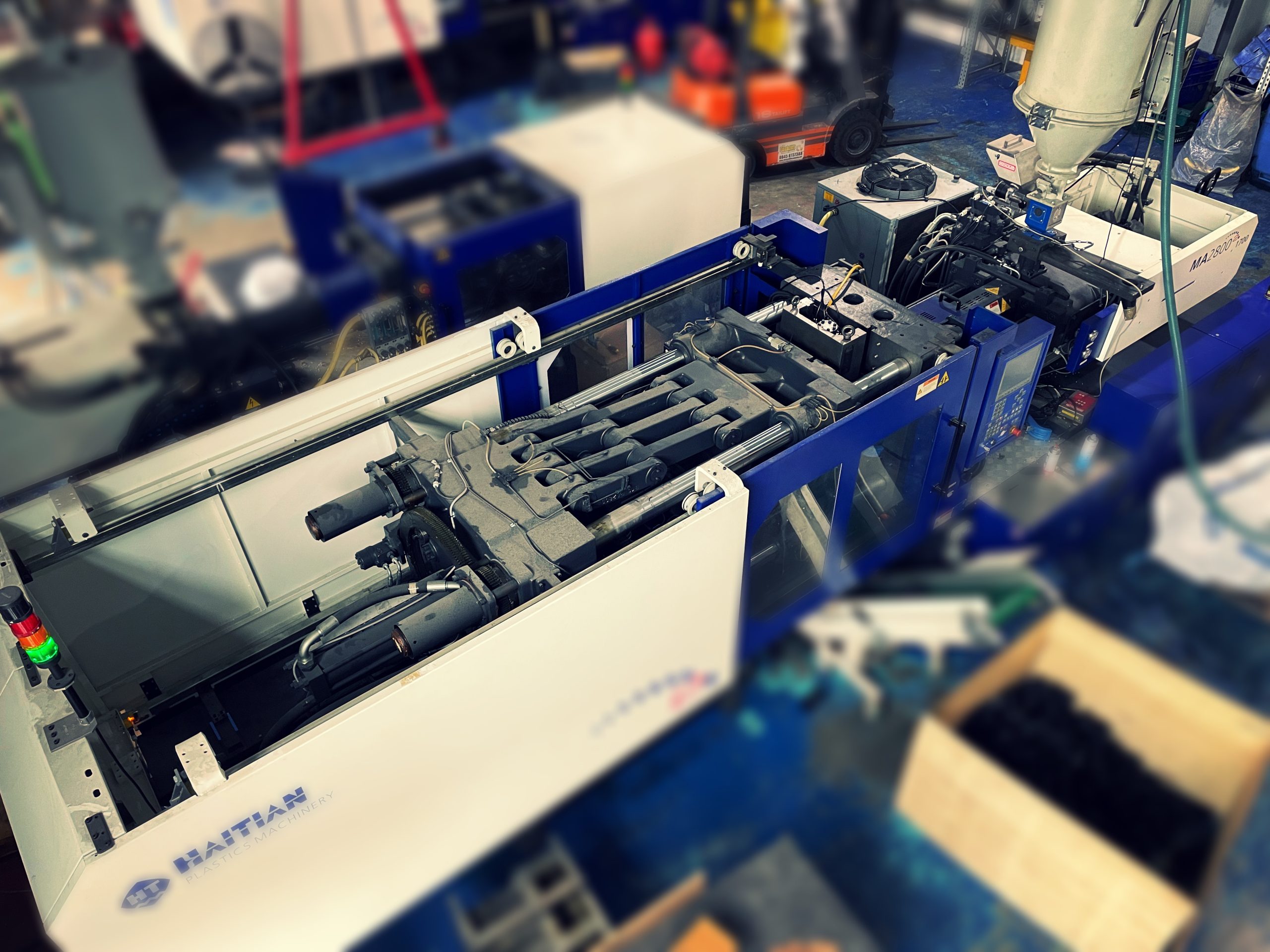

Plastic injection moulding is a sophisticated manufacturing method used to create high-quality plastic parts and products with accuracy.

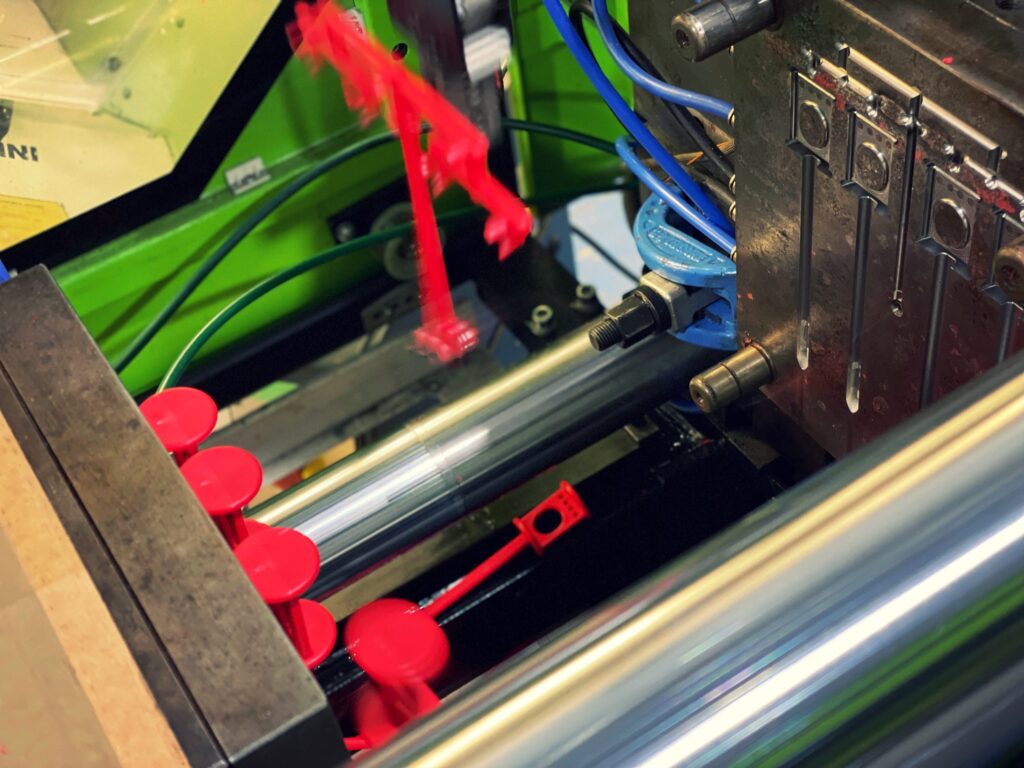

It involves the use of specialised machines and moulds to turn raw plastic materials into finished items that are ready for the market.

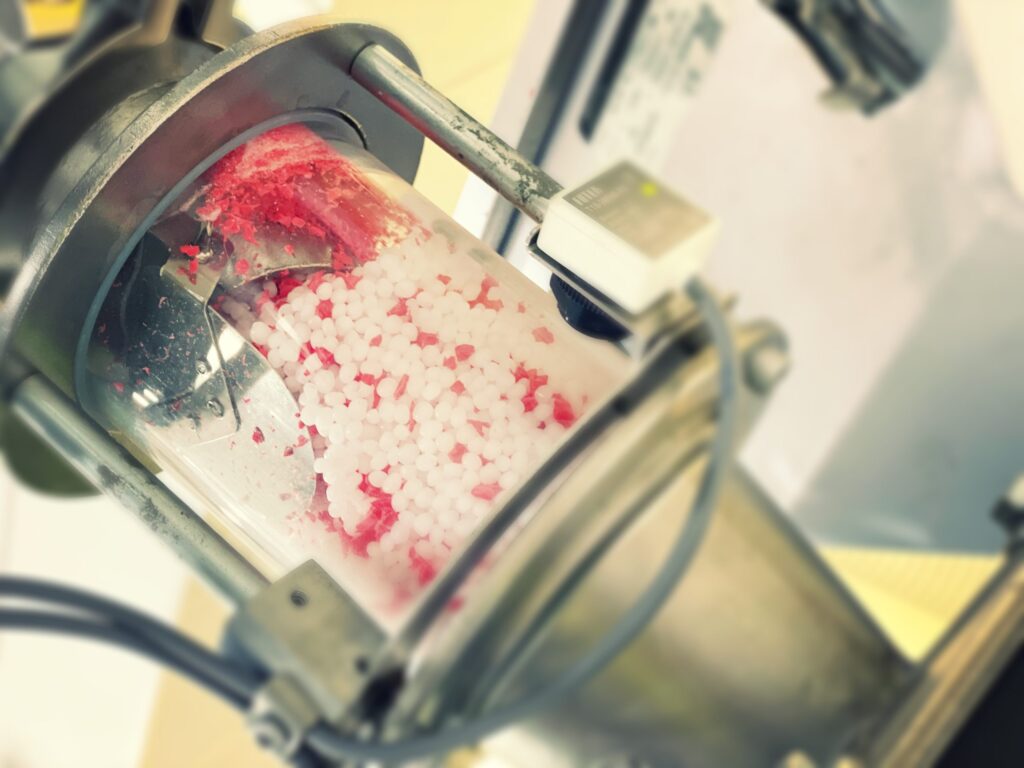

Here’s how it works: first, plastic pellets are melted down and then injected into a pressurised mould cavity. Inside the mould, the plastic cools and hardens, taking on the desired shape.

This technique is commonly used in various industries and is suitable for a wide range of applications and product sizes.

Which Sectors Use Custom Injection Moulding?

Plastic injection moulding plays a crucial role in creating products for a variety of industries, thanks to its adaptability. You’ll find it widely used in sectors like automotive, aerospace, healthcare, consumer goods, and electronics.

At Bosworth Plastics, we combine the latest technology with top-level craftsmanship in everything we make. Our focus is on maintaining high quality throughout our manufacturing process, with our talented team working closely together to deliver exceptional products with precision and care.

The Future Of Manufacturing?

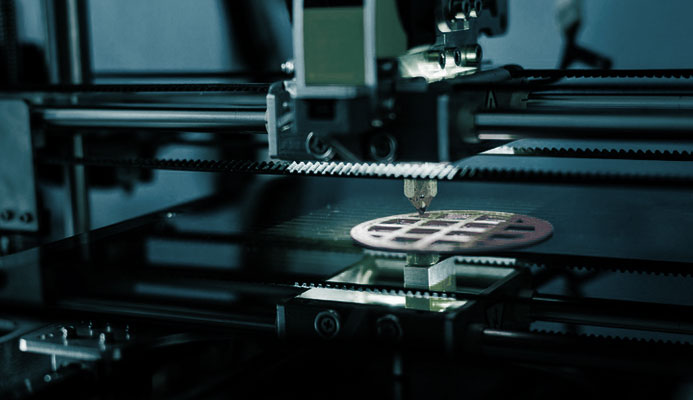

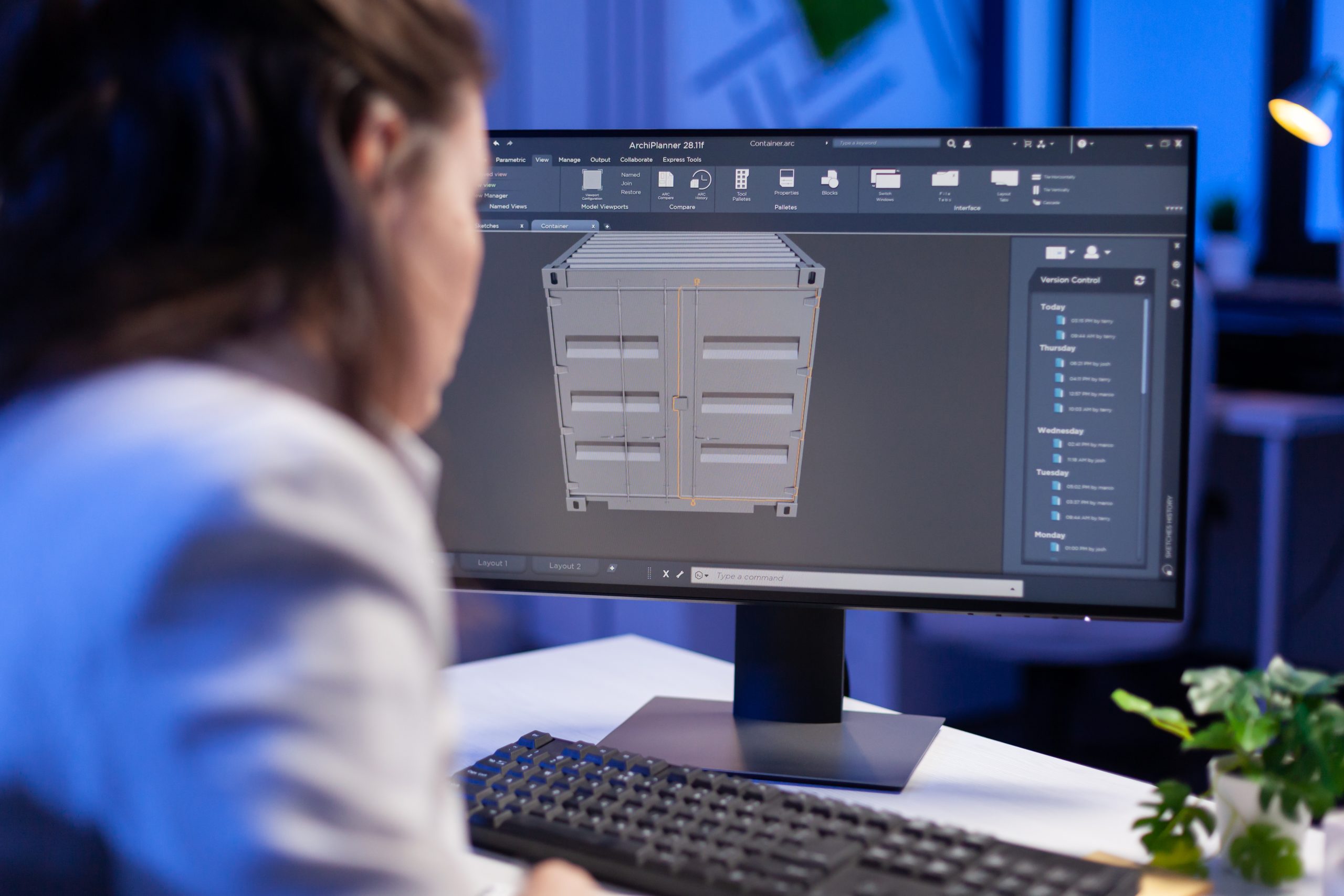

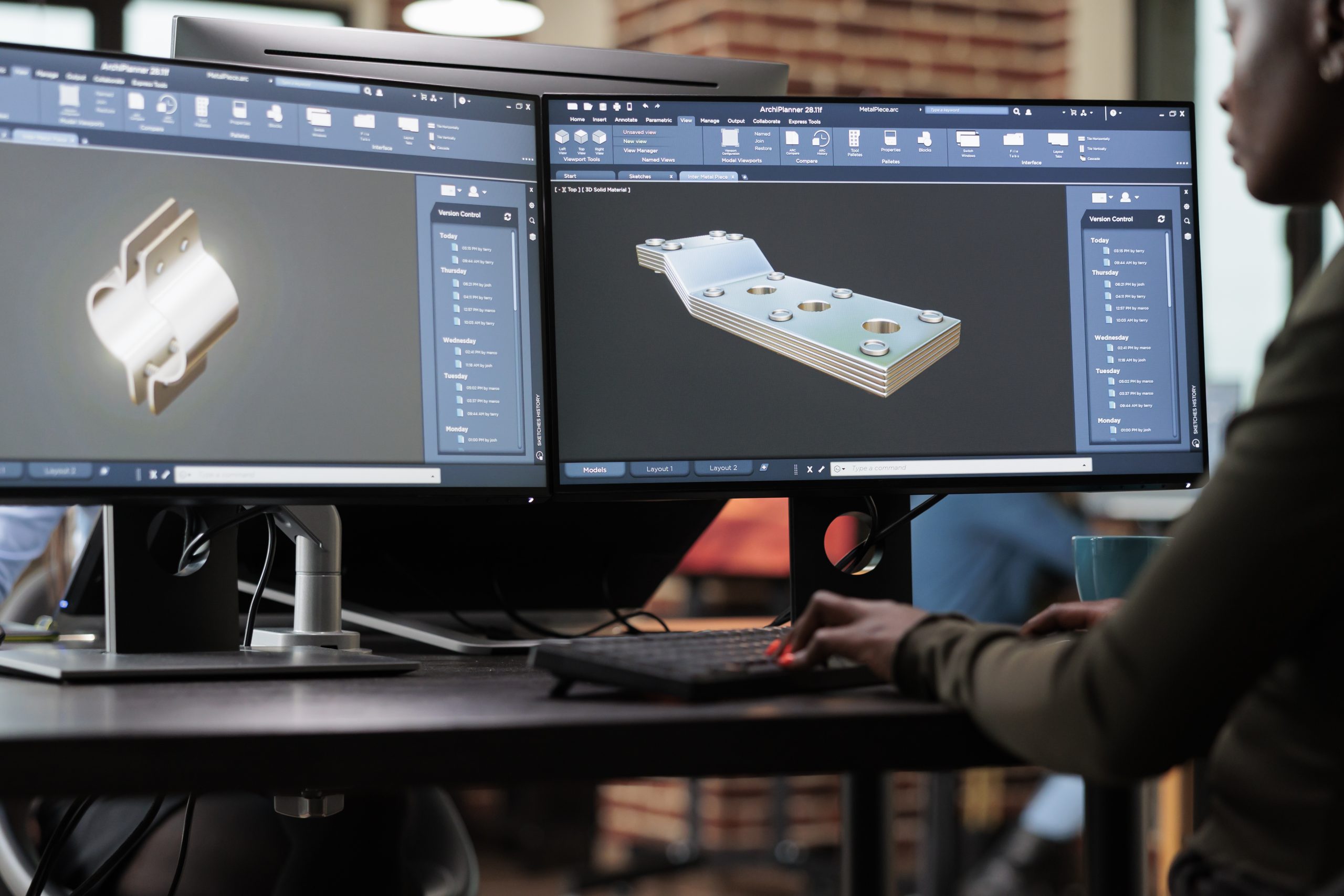

Plastic injection moulding combines the latest technology with innovative tools like computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, along with automation and robotics. This integration greatly improves both product development and the manufacturing process.

In this fast-paced approach, CAD and CAM each have their unique but important roles. CAD takes the first step by creating detailed 3D designs with incredible accuracy, giving manufacturers a clear and precise blueprint for the final product.

Next, CAM systems convert these complex designs into machine-readable instructions, streamlining the manufacturing process and ensuring high standards of accuracy and precision throughout.

In addition, automation and robotics have significantly boosted the efficiency of plastic injection moulding. Automated systems shine in tasks that require high levels of accuracy and speed, like handling materials, loading moulds, ejecting parts, and inspecting quality.

This not only boosts productivity but also minimises errors, making the whole process smoother and more reliable.

Why Choose Us For Custom Injection Moulding?

At Bosworth Plastics, we’re proud to offer top-notch plastic injection mould tooling services specifically designed for the UK manufacturing industry. Our goal is to provide exceptional quality, accuracy, and expertise to our valued clients.

Our advanced facilities are equipped with the latest CAD, CAM, and automated technologies, all operated by our skilled team of plastic injection moulding specialists.

Here’s what you can expect when you work with us:

Expertise In Plastic Injection Moulding

We know that innovation relies on solid industry knowledge, which is why our operations are guided by our experienced team.

Whether you need custom mould tooling, intricate components, or high-volume production, we have the expertise to deliver outstanding results.

With experience across many sectors—like automotive, aerospace, medical devices, and consumer electronics—we’re capable of meeting all your mould tooling needs to an exceptional standard.

Cutting Edge Technology

We’re dedicated to meeting even the toughest industry standards, using state-of-the-art technology and equipment.

Our machines can work with a variety of raw materials, from common plastics to high-performance polymers, giving you the versatility and precision you require for any project.

Plus, we prioritise sustainability, striving to minimise waste and reduce environmental impact throughout the manufacturing process.

Custom Solutions

Every project is unique, so we take a personalised approach to meet your specific needs.

Our experienced engineers and designers work closely with you, ensuring that your mould tool matches your vision while upholding the highest quality standards.

We’re here to provide a comprehensive solution for your mould tooling needs, from prototyping to production, with top-notch customer support every step of the way.

Quality Assurance

Quality is at the heart of everything we do. That’s why we use ISO-certified quality management systems to guarantee that every tool we produce meets your expectations.

Plus, our rigorous quality control processes, from material selection to final inspection, ensure that you receive products that are built to last.

Competitive Pricing

We understand the importance of cost-effectiveness, which is why we offer premium-quality production at fair prices.

Our efficient production methods and economies of scale help you get the best return on your investment while keeping quality high.

On Time Delivery, Every Time

We know that timely delivery is crucial for your business’s professional reputation.

Our streamlined production processes and meticulous project management ensure that your orders arrive when you need them, in perfect condition.

Customer-Centred Services

We put our clients first and take pride in working collaboratively, always welcoming feedback and taking your ideas about product development into account.

Meanwhile, our dedicated customer support team is here to assist you throughout your journey with us, ensuring you get the most value from our services.

Get In Touch!

At Bosworth Plastics, we’re here to be your trusted partner for all your plastic injection mould tooling needs. Whether you’re working on small prototypes or ramping up for large-scale production, we have the knowledge and resources to help you succeed.

Ready to chat about your project? Let’s take the next step together—schedule a consultation with our expert team today!

If You’re Looking For Top-Quality Custom Plastic Injection Moulding, Make Sure You Contact Us!

Plastic Injection Moulded Product Specialist