Custom Injection Mold

Need Custom Injection Molding?

Look No Further Than Bosworth Plastics!

At Bosworth Plastics, we specialise in delivering high-quality custom injection molding for businesses across the UK and beyond. We’re always optimising our services, constantly refining our processes with the latest in CAD, CAM, and automation to deliver faster turnaround times, cost-effective solutions, and consistently outstanding products.

Innovation is at the heart of what we do. Through ongoing research and development, we collaborate with industry experts and embrace new technologies to keep improving. This commitment means our clients don’t just get great service—they get exceptional results that exceed expectations!

What Is Plastic Injection Molding?

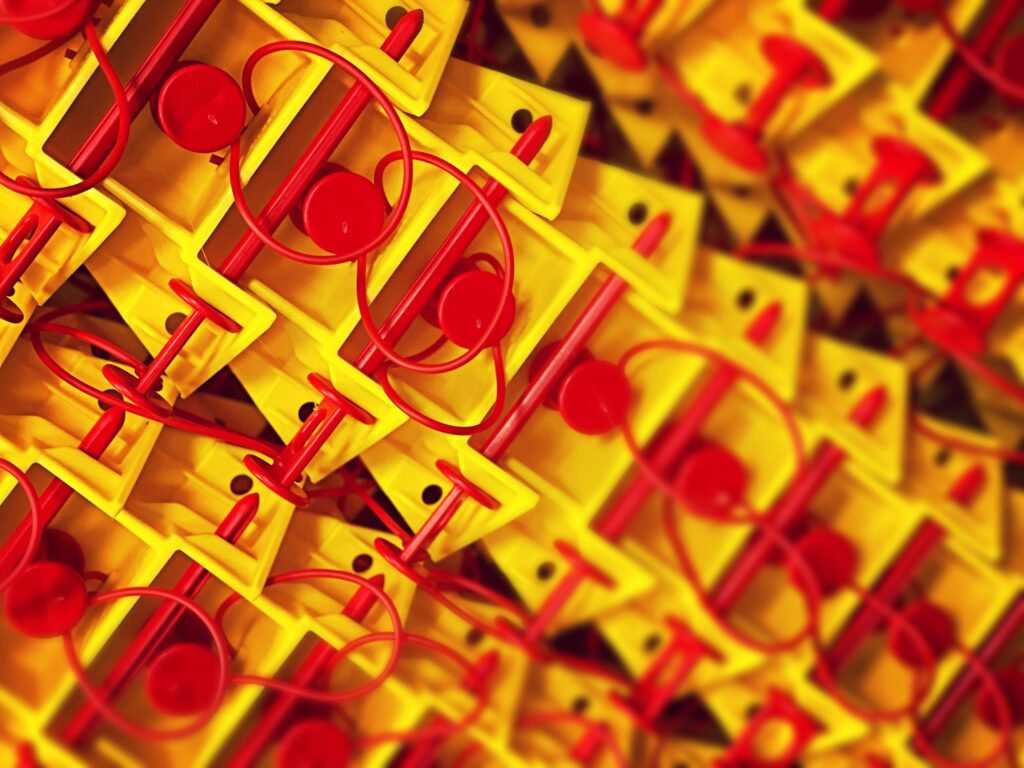

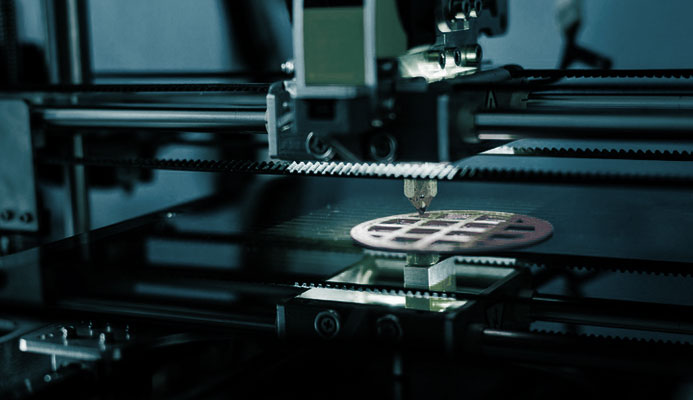

Plastic injection molding is a highly efficient way to produce precise, high-quality plastic parts and products.

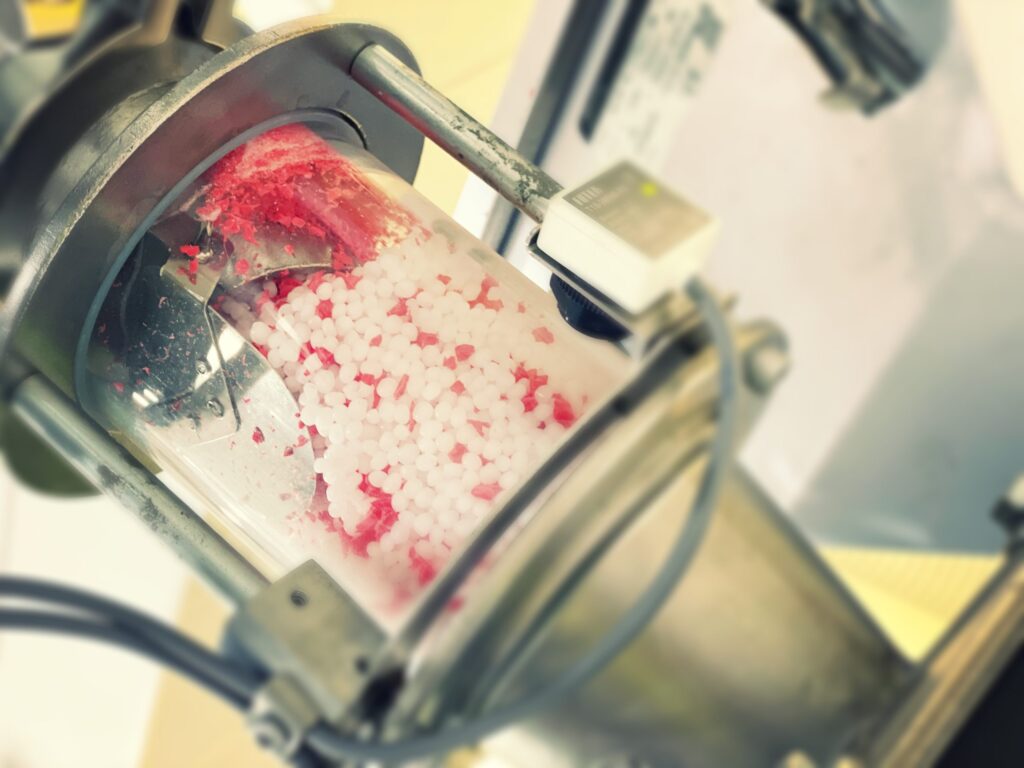

It works by melting plastic pellets and injecting the liquid material into a mold under pressure. As the plastic cools and hardens, it takes on the exact shape of the mold, creating a finished product ready for use.

This process is used across many industries to manufacture everything from small, intricate components to large, durable parts. Its versatility and precision make it a go-to method for producing a wide range of plastic products at scale.

Which Sectors Use Custom Injection Molding?

Plastic injection molding is a common manufacturing method for countless industries, from automotive and aerospace to healthcare, consumer goods, and electronics. Its versatility makes it essential for producing a huge range of products, both big and small.

At Bosworth Plastics, we combine the latest technology with expert craftsmanship to deliver high-quality outcomes. Quality control is at the heart of everything we do, with our skilled team working closely to ensure every product meets the highest standards of precision and excellence.

The Future Of Manufacturing?

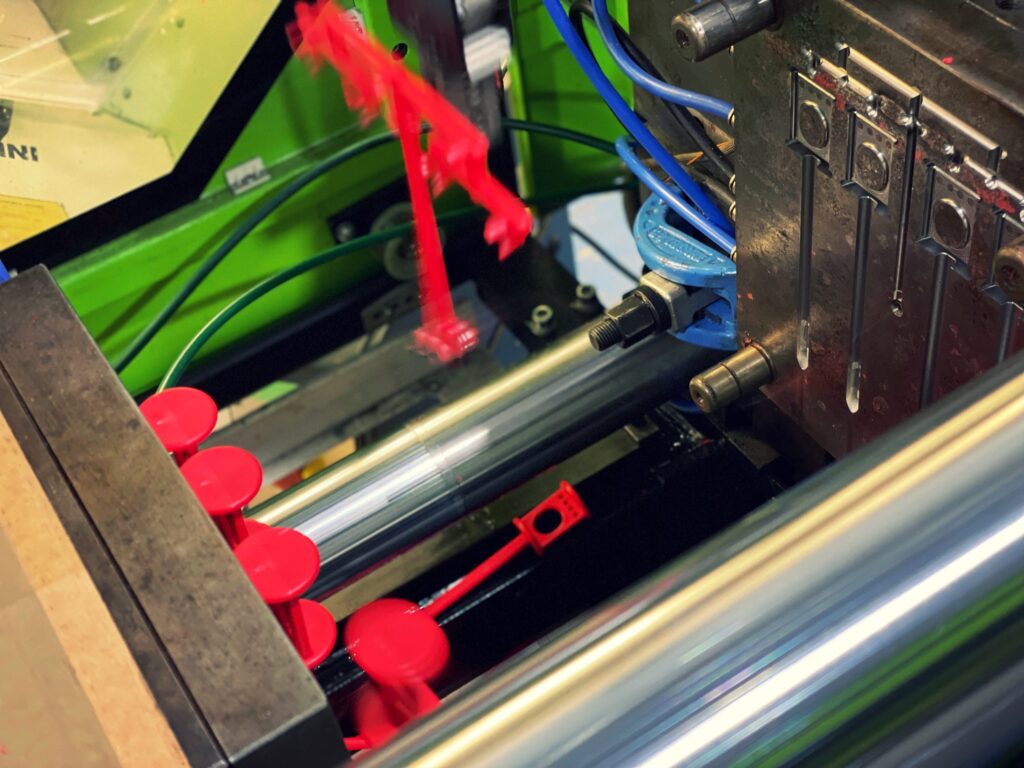

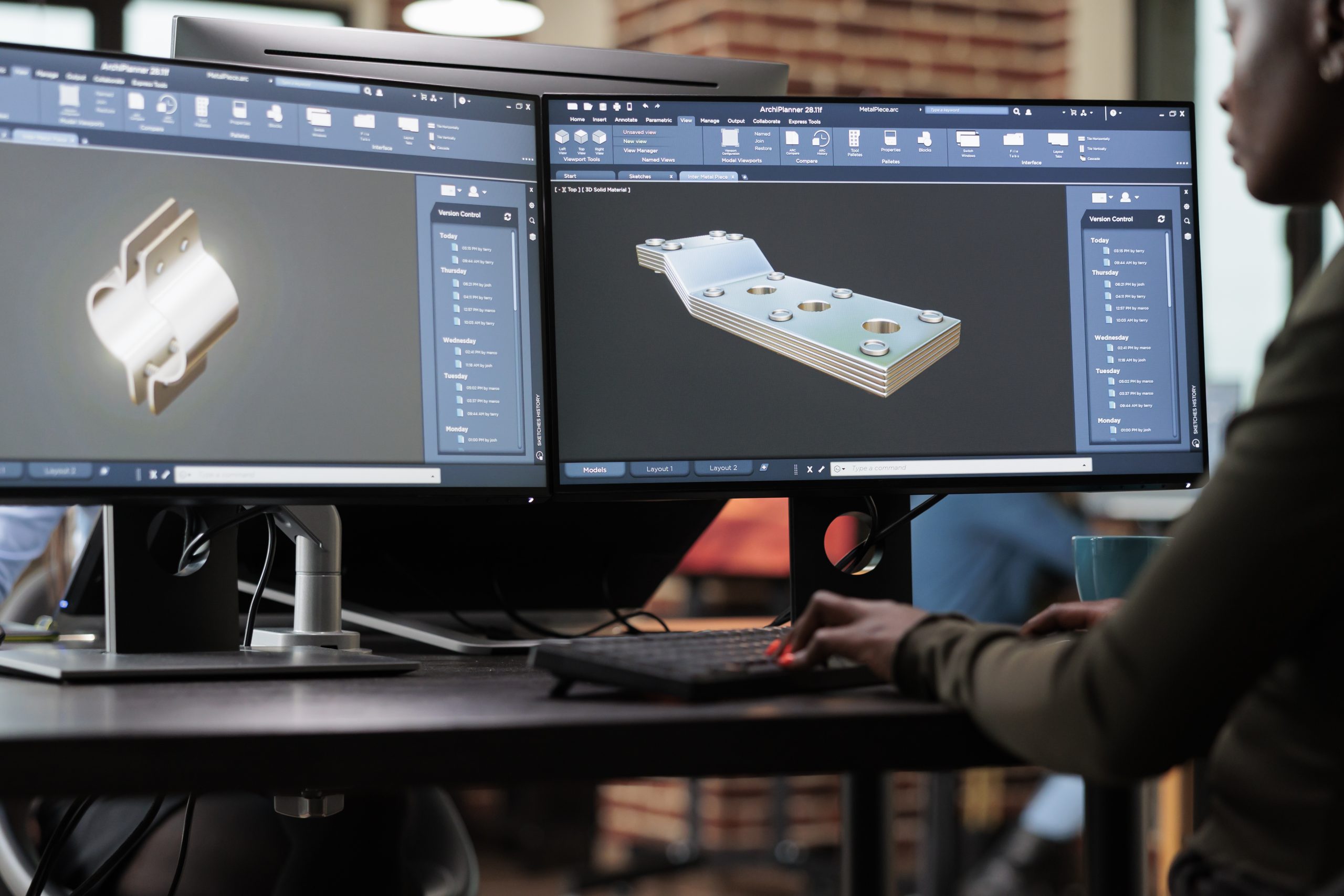

Plastic injection molding has come a long way, thanks to advancements in technology. By integrating computer-aided design (CAD), computer-aided manufacturing (CAM), automation, and robotics, the process has become more efficient, precise, and reliable.

CAD software is where it all begins, creating highly detailed 3D designs that serve as the blueprint for the final product. CAM then takes over, converting those designs into machine-readable instructions, ensuring every stage of production follows the exact specifications.

Automation and robotics further streamline the process, handling tasks like material loading, mold operation, part ejection, and quality checks with incredible speed and accuracy. Not only does this improve efficiency, but it also minimises errors, leading to high-quality results every time.

Why Choose Us When You Need A Custom Injection Mold?

At Bosworth Plastics, we focus on precision, innovation, and expert craftsmanship, ensuring our clients receive the best possible products.

Our advanced facilities are equipped with the latest CAD, CAM, and automated technologies, operated by a highly skilled team with years of industry experience.

Here’s what sets us apart:

Expertise In Plastic Injection Molding

With extensive experience across industries like automotive, aerospace, medical devices, and consumer electronics, we have the know-how to handle everything from custom mold tooling to high-volume production.

No matter how complex the project, we deliver with precision and reliability!

Cutting-Edge Technology

We use state-of-the-art machinery to create tooling from a variety of materials, including both standard plastics and high-performance polymers.

Our commitment to sustainability means we also minimise waste and reduce environmental impact at every stage of production.

Custom Solutions

Every project is unique, so we take a tailored approach.

Our engineers and designers work closely with you to develop mold tools that meet your exact requirements, ensuring the final product aligns with your vision and meets the highest quality standards.

Quality Assurance

We follow ISO-certified quality management systems to guarantee consistency and durability in everything we produce.

Every mold tool goes through rigorous quality checks, from material selection to final inspection, so you can trust that our products will stand the test of time.

Cost-Effective Solutions

High-quality production doesn’t have to come with a high price tag.

Our efficient manufacturing processes allow us to offer competitive pricing without compromising on quality, helping you maximise your return on investment.

Reliable Delivery, Every Time

We understand how critical deadlines are in manufacturing.

Our streamlined production and strong project management ensure your orders are delivered on time, every time, and in perfect condition.

Customer-Focused Service

We believe in collaboration and open communication. Our team is here to support you throughout the process, from concept to completion, ensuring you get the most value from our services.

At Bosworth Plastics, we’re more than just a supplier—we’re a trusted partner in bringing your ideas to life.

Get In Touch If You’re Looking For Custom Injection Molding!

At Bosworth Plastics, we’re here to support you with expert plastic injection mold tooling, whether you need a single prototype or full-scale production. With our experience and resources, we can bring your project to life with precision and efficiency.

Ready to get started? Reach out to our team today—we’re here to help!

If You Need A Top-Quality Custom Injection Mold, Make Sure You Contact Us!

Plastic Injection Moulded Product Specialist