Plastic Injection Molding Companies

Need A Plastic Injection Molding Company?

Look No Further Than Bosworth Plastics!

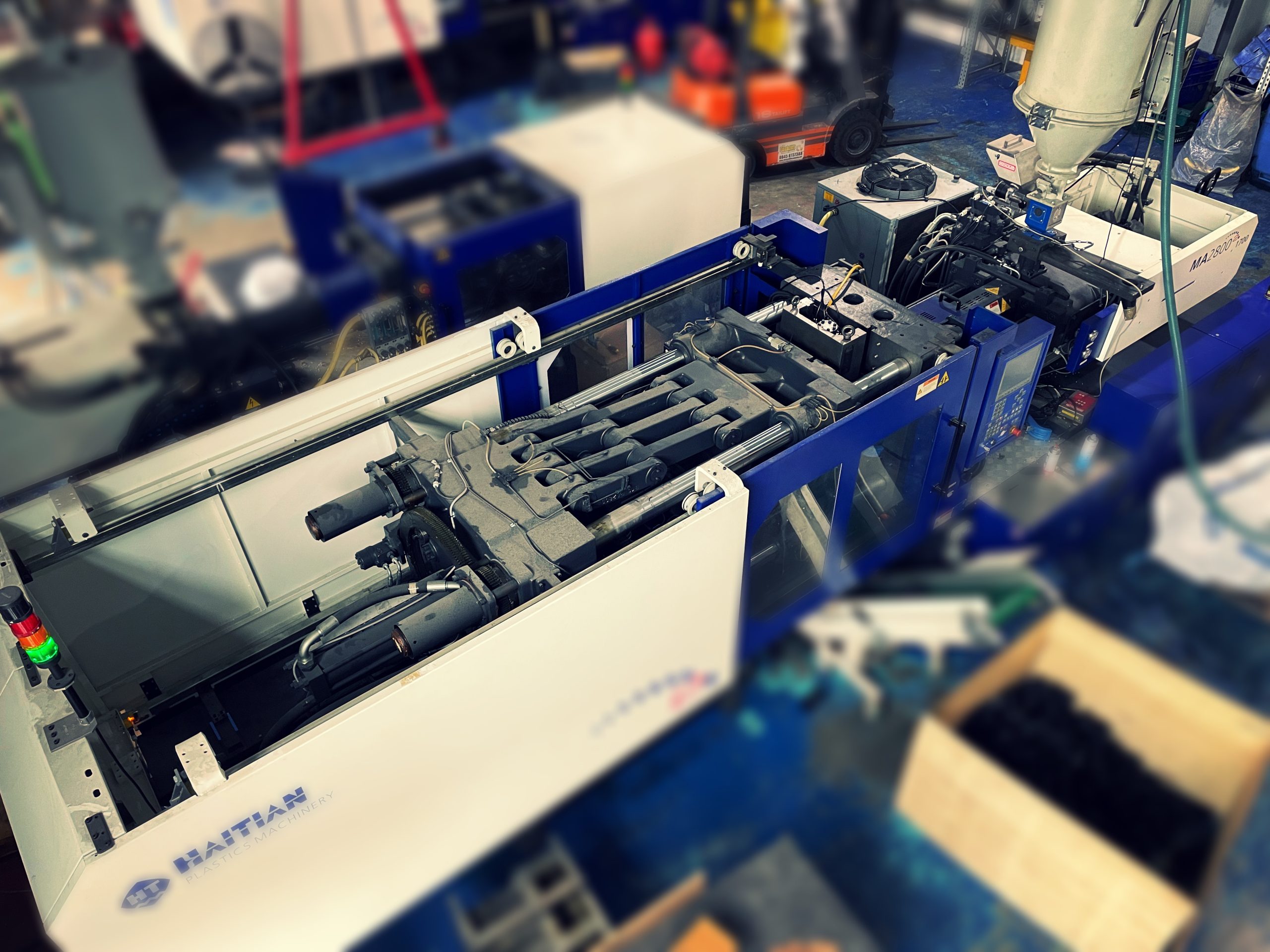

At Bosworth Plastics, we’re a plastic injection molding company dedicated to providing exceptional mold tooling services to our prestigious blue-chip clients throughout the UK and beyond.

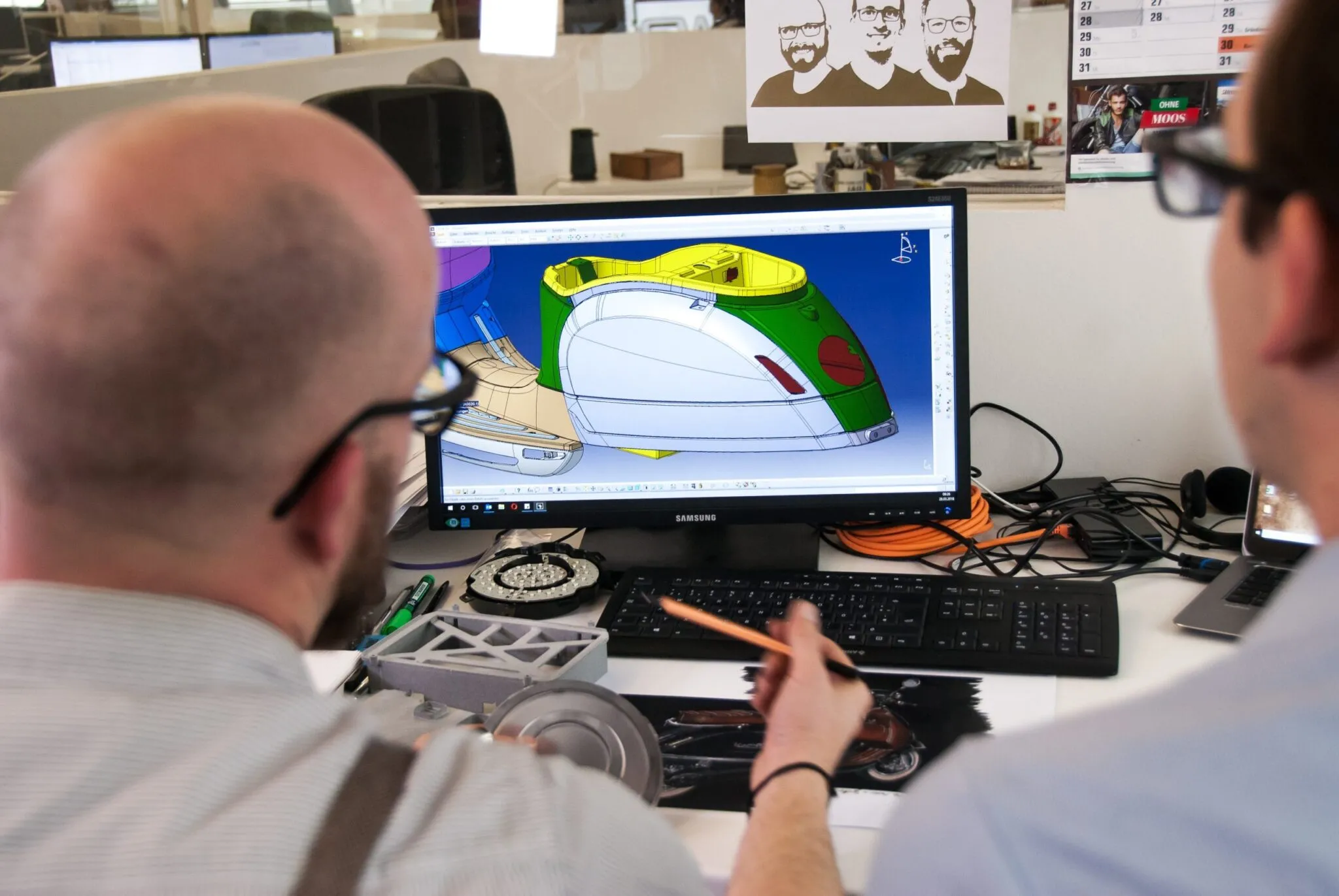

Our reputation is built upon an unwavering commitment to quality, precision engineering, and outstanding customer service. With a highly skilled team of specialists and the latest automated CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) technologies, we ensure that every project meets the most rigorous industry standards!

Based in our advanced facility in Leicestershire, our team of plastic injection molding experts combines technical proficiency with innovative problem-solving to deliver superior results. Whether you require bespoke tooling for specialised applications or high-volume production runs, Bosworth Plastics is fully equipped to handle your requirements!

What Do Plastic Injection Molding Companies Do?

What Does A Plastic Injection Molding Company Do?

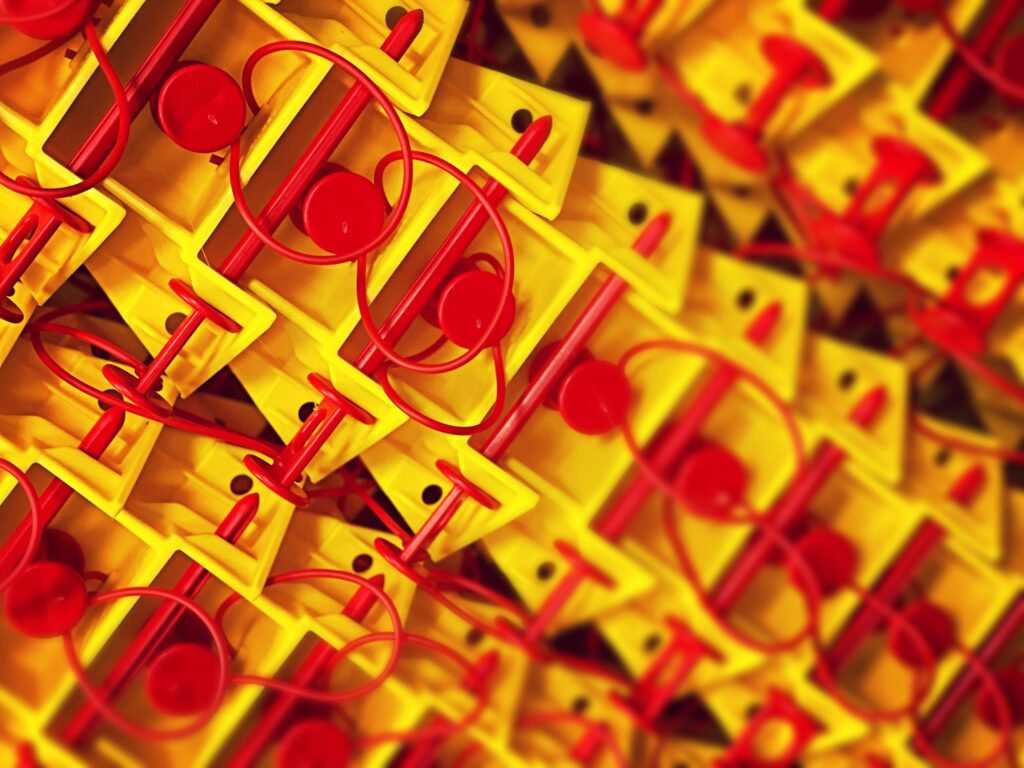

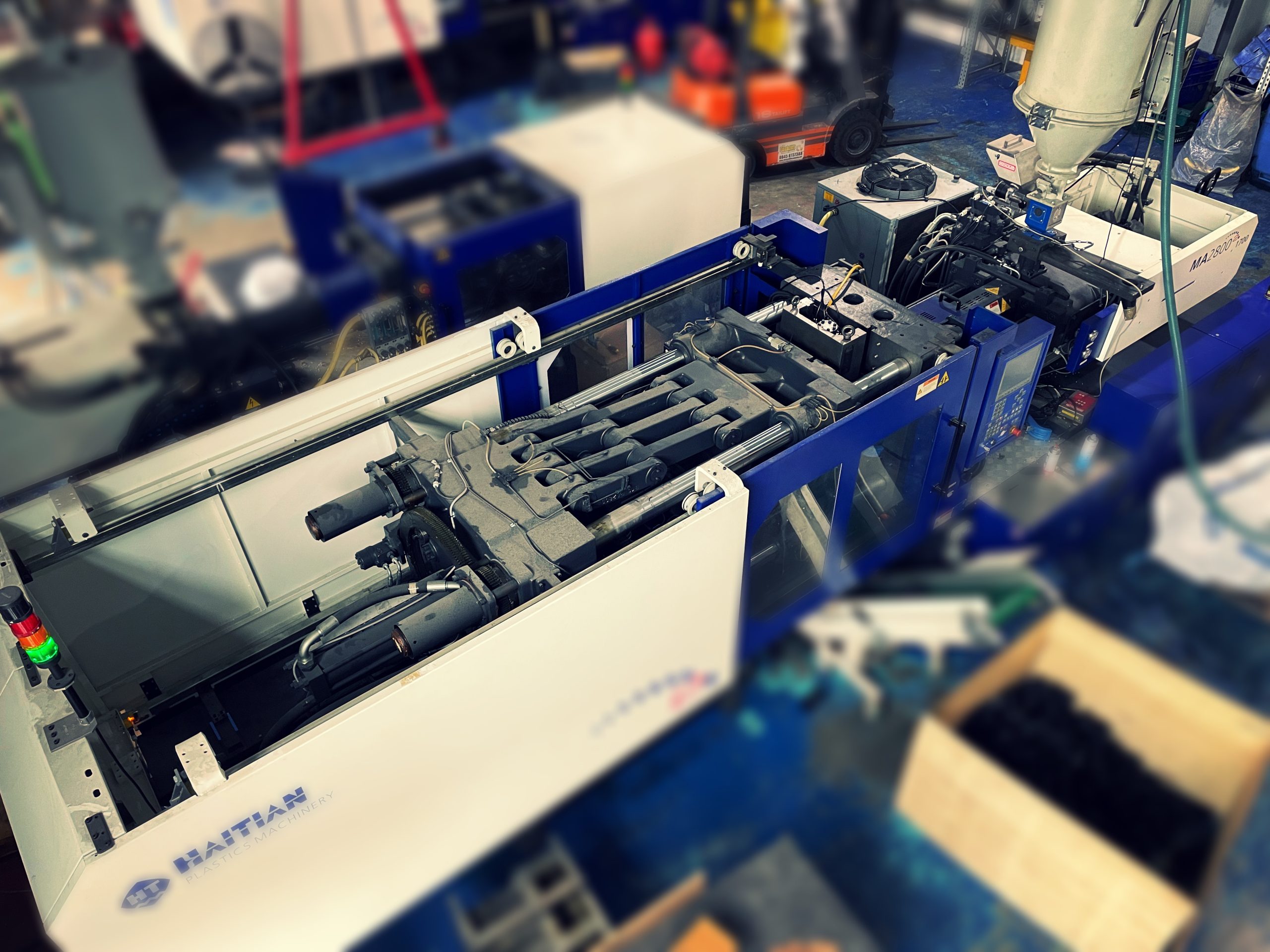

Plastic injection molding is a highly efficient manufacturing process used to produce precision-engineered plastic components.

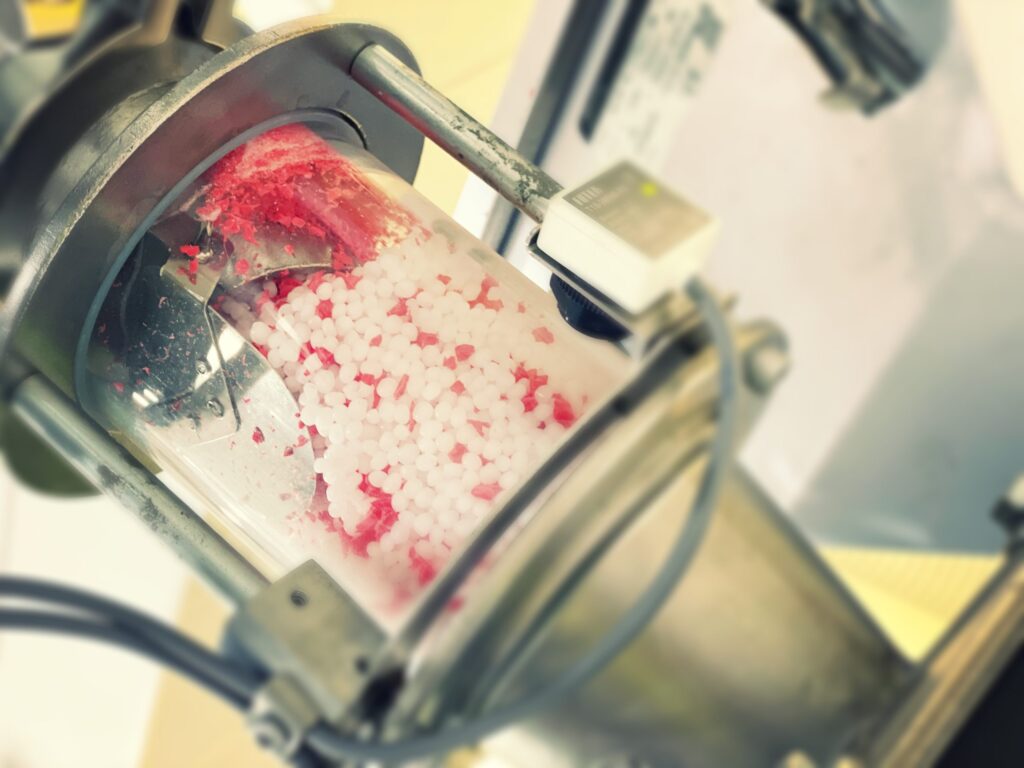

The technique involves melting raw plastic pellets and injecting the molten material into a pressurised mold cavity. Once inside the mold, the plastic cools and solidifies, taking on the desired shape before being ejected as a finished product.

This process is widely favoured for its ability to produce intricate geometries with exceptional accuracy and repeatability. From small, delicate components to large industrial parts, plastic injection molding is a versatile solution that serves a wide range of industries.

The Applications Of Plastic Injection Molding

The adaptability of plastic injection molding makes it indispensable across numerous sectors, including:

- Healthcare – Used for medical devices, syringes, surgical instruments, and diagnostic equipment.

- Automotive – Used for dashboard components, interior trim, engine parts, and lightweight structural elements.

- Aerospace – Used for high-strength, lightweight components for aircraft and spacecraft.

- Consumer Goods – Used for packaging, household items, electronic enclosures, and toys.

- Industrial Manufacturing – Used for machine components, fittings, and custom tooling.

At Bosworth Plastics, we leverage our extensive industry expertise and cutting-edge technology to produce molds that meet the exacting standards of these diverse applications. Our stringent quality control measures ensure that every component we manufacture adheres to the highest levels of performance.

The Future Of The Manufacturing Industry?

The manufacturing industry is undergoing a significant transformation, driven by advancements in technology such as CAD/CAM systems, automation, and robotics.

These innovations have revolutionised plastic injection molding, enhancing efficiency, accuracy, and scalability.

The Role Of CAD And CAM In Modern Manufacturing

- CAD (Computer-Aided Design) – This system enables engineers to create detailed 3D models of products, providing a digital blueprint for mold design.

- CAM (Computer-Aided Manufacturing) – Once the design is finalised, CAM software translates it into machine-readable instructions, ensuring precise and efficient production.

The seamless integration of these systems facilitates a smooth transition from design to manufacturing, reducing errors and accelerating lead times.

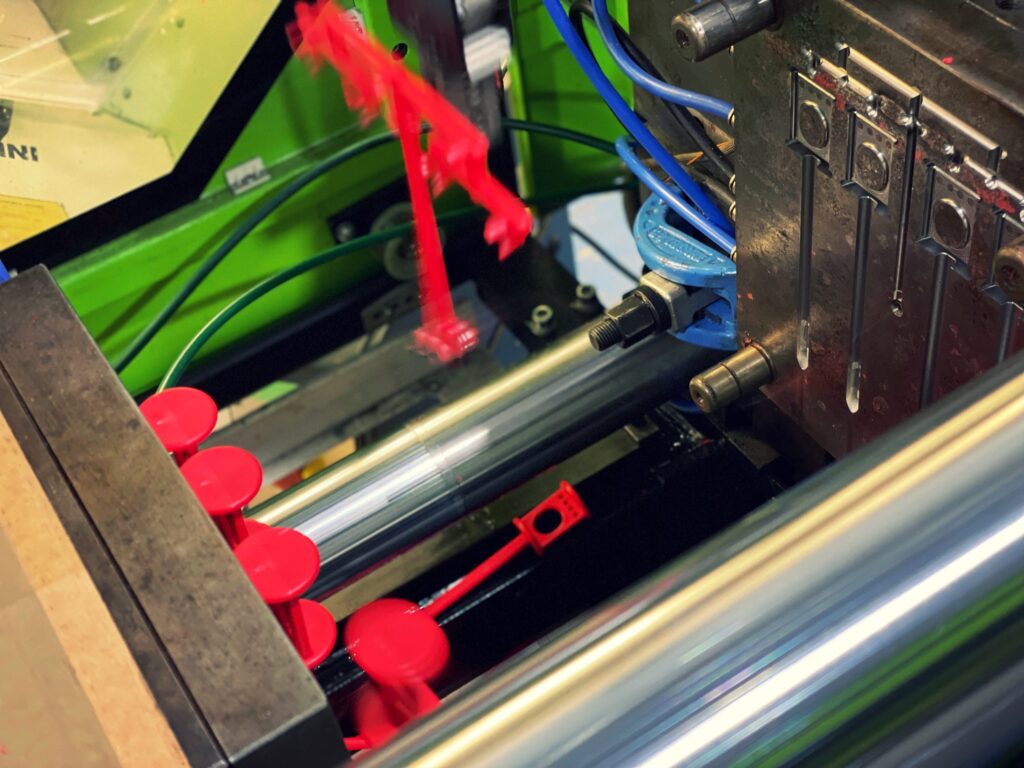

Automation has dramatically improved the efficiency of plastic injection molding by handling repetitive tasks with unmatched speed and precision.

Key applications include:

- Material Handling – Automated systems consistently feed raw plastic pellets into machines.

- Mold Loading/Unloading – Robotics ensure exact placement and removal of molds.

- Quality Inspection – Automated vision systems detect defects in real-time, maintaining stringent quality standards.

By minimising manual intervention, these technologies enhance productivity while reducing the risk of errors, making them indispensable in modern manufacturing.

Why Choose Us When You Need A Plastic Injection Molding Company?

Why Choose Us When You Need Plastic Injection Molding Companies?

At Bosworth Plastics, we focus on precision, innovation, and expert craftsmanship, ensuring our clients receive the best possible products.

Our advanced facilities are equipped with the latest CAD, CAM, and automated technologies, operated by a highly skilled team with years of industry experience.

Here’s what sets us apart:

Innovative Technology

We continuously invest in the latest manufacturing technologies to maintain the highest industry benchmarks. Our state-of-the-art machinery is capable of processing an extensive range of raw materials, from standard thermoplastics to high-performance engineering polymers.

This versatility allows us to provide tailored solutions that align precisely with your project specifications. By integrating automation and precision engineering into our processes, we achieve unparalleled accuracy in every mold we produce.

Furthermore, we are committed to sustainable manufacturing practices, implementing waste-reduction strategies across our production lines. This not only minimises our environmental impact but also ensures cost-efficient solutions for our clients.

Tailored Services

We understand that every client has unique requirements, so a generic approach is insufficient for delivering optimal results.

That is why we offer fully customised mold tooling solutions, meticulously designed to meet your business objectives, technical demands, and quality expectations.

Our philosophy is rooted in collaboration and transparent communication. From the initial design consultation to final production, our specialists work closely with you to ensure the end product aligns perfectly with your vision.

We actively incorporate your feedback at every stage, guaranteeing that the finished mold tool not only fulfils functional requirements but also adheres to stringent quality control measures for market-ready performance.

Our comprehensive service offering spans the entire production lifecycle, including:

- Prototyping – Testing designs for feasibility and performance before full-scale production

- Tool Design – Engineering molds with precision using advanced CAD software

- Mold Manufacturing – Crafting durable, high-performance tools with exacting tolerances

- Full-Scale Production – Delivering consistent, high-quality components at volume

Supported by our dedicated customer service team, we ensure a seamless experience from concept to completion. Should any issues arise, we are committed to resolving them swiftly and effectively.

Quality Assurance

Quality assurance is the foundation of our operations. To uphold the highest standards, we employ ISO-certified quality management systems that govern every stage of our manufacturing process.

This rigorous framework ensures that each mold tool we produce meets the exacting demands of our distinguished clientele.

Our quality control process begins with the careful selection of raw materials and extends through every phase of production, culminating in a thorough final inspection.

By maintaining stringent checks, we guarantee that every tool leaving our facility meets the precision, durability, and performance required for even the most demanding applications.

When you choose Bosworth Plastics, you invest in a service that exemplifies engineering excellence!

Cost-Effective Rates

We recognise that commercial success depends not only on superior quality but also on cost efficiency. That is why we deliver premium mold tooling services at highly competitive rates.

Through optimised production techniques and economies of scale, we maximise efficiency to provide outstanding value without sacrificing quality. Our approach ensures that clients achieve an excellent return on investment (ROI) while maintaining the high standards essential in today’s marketplace.

Whether you are a start-up seeking affordable tooling solutions or an established manufacturer requiring large-scale production support, we offer a financially viable pathway to success.

Reliable Timekeeping

In the fast-paced manufacturing sector, meeting deadlines is crucial. Delays can disrupt supply chains, strain client relationships, and damage business reputations.

That’s why our team is dedicated to adhering to all agreed timelines, ensuring that your mold tools are delivered on schedule, without exception. Through efficient planning and advanced manufacturing techniques, we proactively mitigate potential bottlenecks, allowing you to proceed with confidence knowing your project is in expert hands!

Contact Us If You Need A Plastic Injection Molding Company!

As a leading provider of plastic injection mold tooling services, we are committed to delivering excellence at every stage of production. Our customer-focused approach ensures that you remain central to the manufacturing process, from initial prototyping to full-scale production.

If you have any questions about our services or would like to discuss your project requirements, our expert team is ready to assist. Contact us today to schedule a consultation and receive a free, no-obligation quote.

At Bosworth Plastics, we do not just manufacture molds—we build enduring partnerships founded on quality, reliability, and innovation. Let us help you bring your vision to life with precision-engineered solutions tailored to your specific needs!

If You Need Top-Quality Plastic Injection Molding Companies, Make Sure You Contact Us!

Plastic Injection Moulded Product Specialist