In the dynamic world of UK manufacturing, Bosworth Plastics stands proud as a trusted name in injection moulding – known not only for quality and precision, but for a clear commitment to investment, innovation, and engineering excellence.

For over 20 years, we’ve been moulding the future of countless products and components across a wide range of industries. But what really sets us apart? Let’s take you behind the scenes of our operations to show how we bring ideas to life – with accuracy, consistency, and unmatched capability.

A Testament to Investment

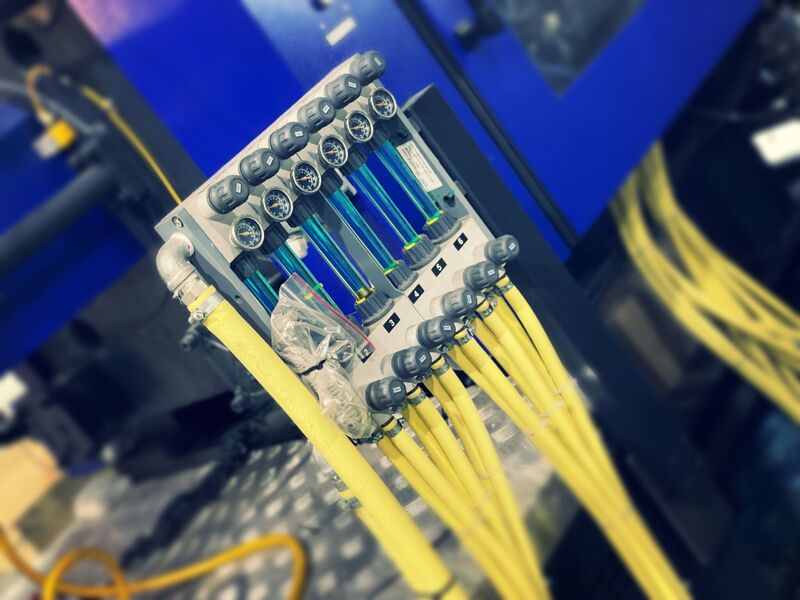

At Bosworth Plastics, we see our mould shop not just as a workspace, but as a living expression of our ambition and high standards. Every investment, whether in cutting-edge machinery, automation, or skilled personnel, reflects our goal of delivering exceptional results for every project, large or small.

From design to delivery, our facilities are optimised to support quality, flexibility, and speed – ensuring we meet the evolving demands of modern manufacturing.

The Power of Machinery

At the heart of our business lies our impressive line-up of injection moulding machines, ranging from 90 tonnes to 390 tonnes in capacity. This diversity enables us to handle a broad spectrum of projects in-house, from intricate technical parts to larger structural components.

Each machine operates with the precision our clients have come to rely on – and with robotics integrated into our processes, we take that precision even further. Robotics enable greater consistency, enhanced efficiency, and the ability to run ‘lights-out production’ where required – offering uninterrupted manufacturing with the highest quality standards maintained.

A Symphony of Technology and Expertise

What you’ll find at Bosworth Plastics is more than just machinery. You’ll find a team of passionate professionals, each bringing experience and specialist knowledge to the table. Our engineers, technicians and quality control teams work together to ensure that every part we produce is made to exacting specifications.

From the first concept to the final product, every stage of the moulding journey is handled with care, precision, and a dedication to getting things right.

Why Choose Bosworth Plastics?

✅ Over 20 years of injection moulding experience

✅ Versatile machine capacity (90–390 tonnes)

✅ Advanced automation & robotics

✅ In-house expertise and customer-focused service

✅ Trusted UK manufacturer

Whether you’re launching a new product or scaling up production of an existing one, Bosworth Plastics is ready to support you with the technology, capacity, and know-how to make it happen.

Ready to bring your next project to life?

Get in touch with our team to learn more about our injection moulding capabilities – and discover why more UK manufacturers are choosing Bosworth Plastics as their go-to moulding partner.