Plastic Moulding Companies UK

Searching For Plastic Injection Moulding UK?

Look No Further Than Bosworth Plastics!

At Bosworth Plastics, we’re proud to deliver exceptional plastic injection moulding services to many blue-chip clients in the UK’s manufacturing sector. Our services are trusted by leading companies who rely on us for consistency, accuracy, and engineering excellence.

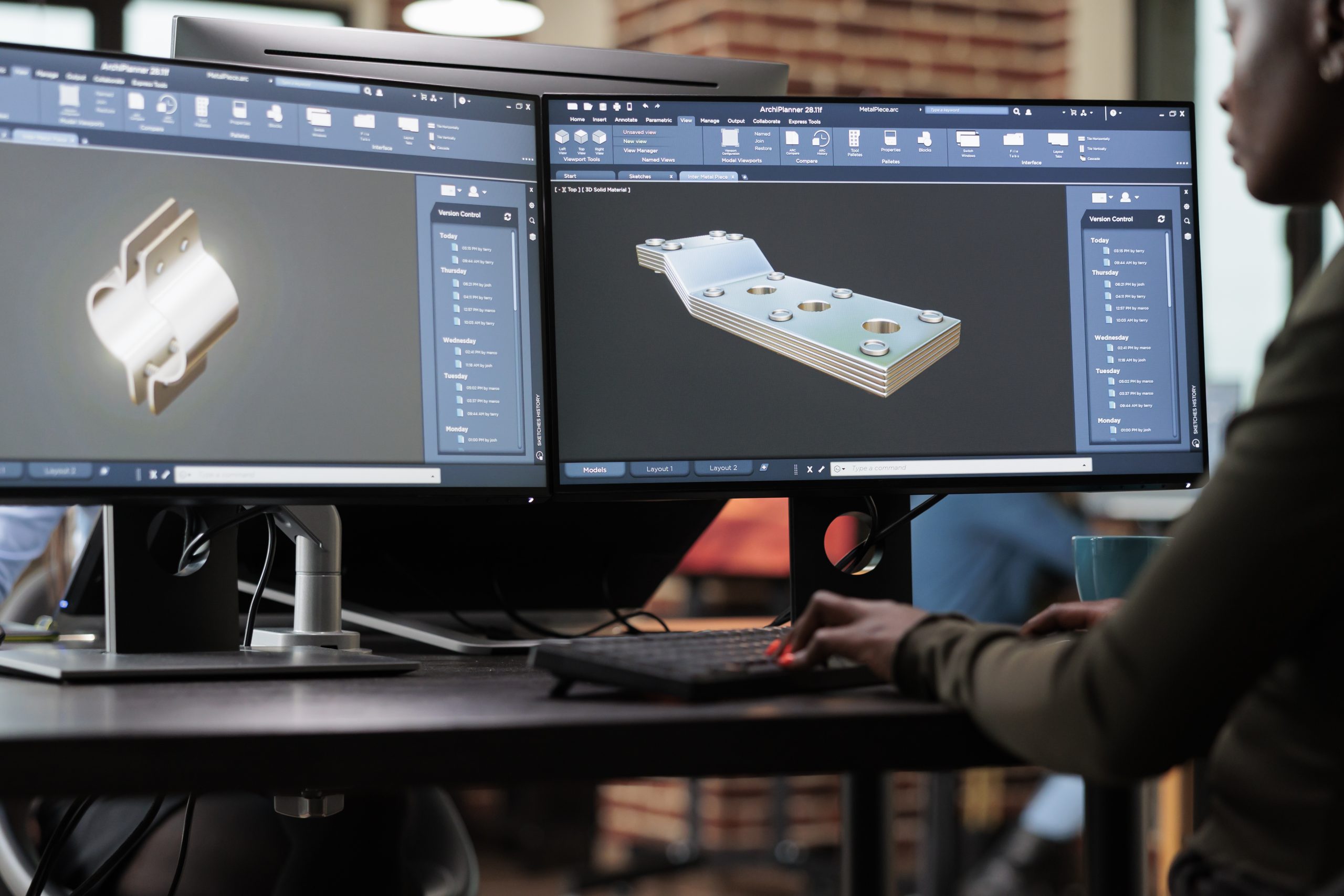

With a strong focus on precision, professionalism, and the latest technology, we ensure that every project we undertake meets the highest quality standards. Our team is composed of highly skilled specialists with years of experience in the field, supported by advanced, automated CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) systems.

This combination allows us to create precise, reliable mould tools for a wide range of industrial applications.

What Do UK Plastic Moulding Companies Do?

What Is Plastic Injection Moulding UK?

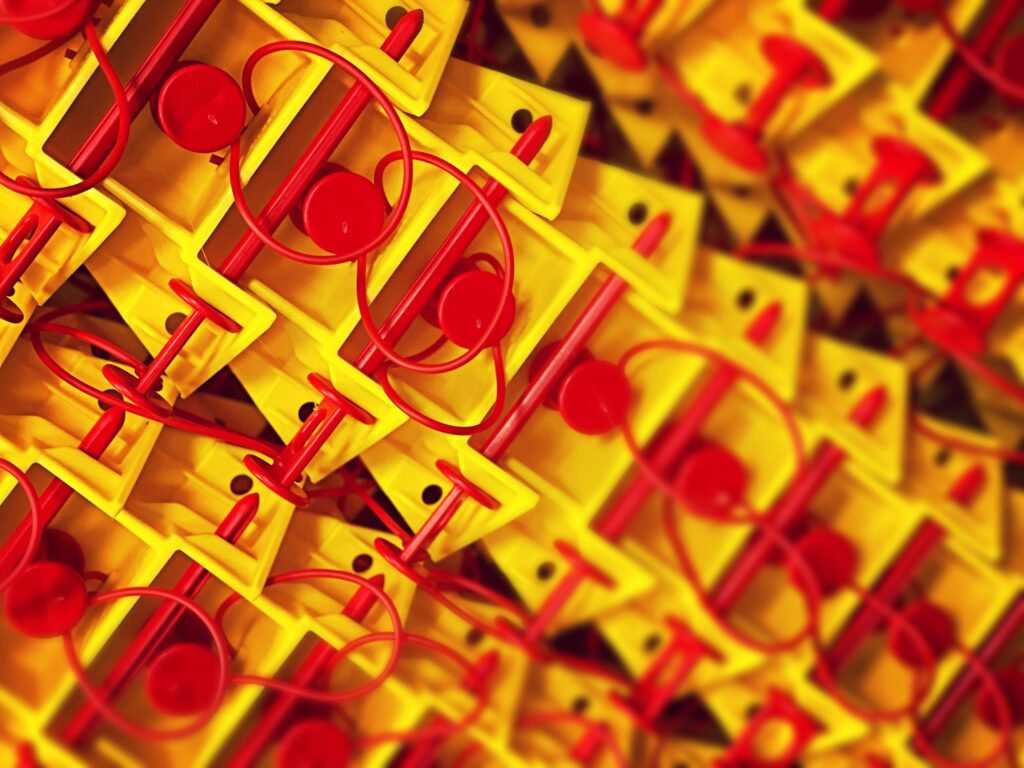

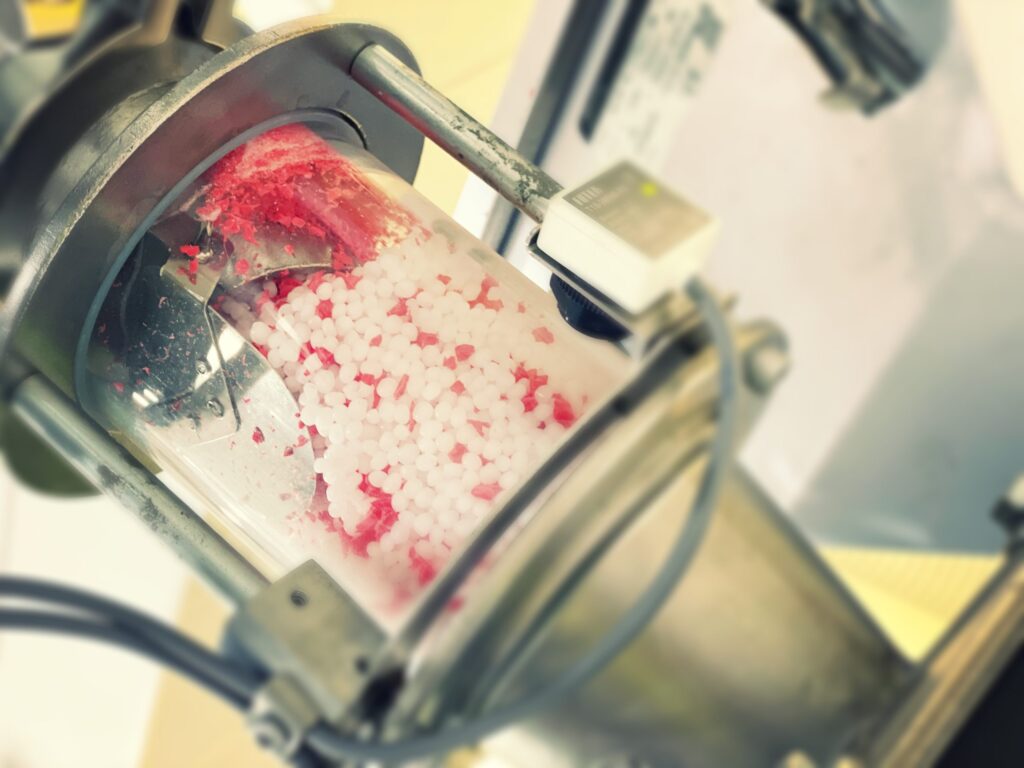

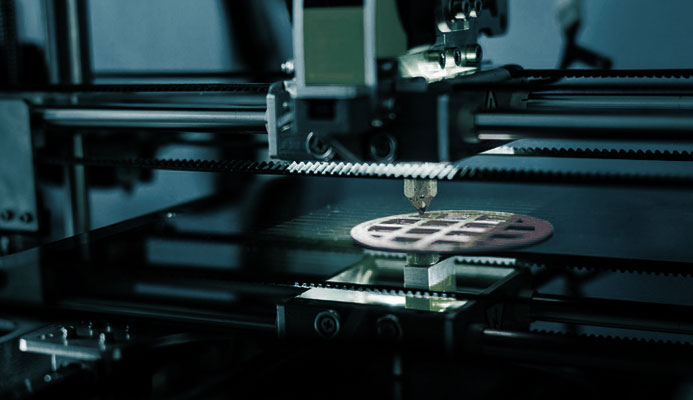

The plastic injection moulding process begins by melting plastic pellets, which are then injected into a steel or aluminium mould under high pressure. Once the molten plastic fills the mould cavity, it is cooled and hardened into the desired shape.

This method is incredibly efficient and is widely used to produce everything from simple plastic parts to complex, high-performance components. It is known for its ability to deliver high accuracy, repeatability, and speed, making it ideal for industries such as automotive, medical, electronics, consumer goods, and aerospace.

With modern machinery and automation, plastic injection moulding allows for tight tolerances and consistent part quality — even across millions of units.

The Applications Of Plastic Injection Moulding

Injection moulding is used in nearly every sector that relies on plastic components. Its versatility allows manufacturers to produce parts in various sizes, shapes, and levels of complexity — all with incredible consistency.

From medical devices and car dashboards to mobile phone housings and food packaging, injection moulding is a cornerstone of global production. It enables rapid product development, supports complex geometries, and ensures strength and durability where needed.

At Bosworth Plastics, we combine decades of experience with the latest production technologies to provide tooling solutions that empower manufacturers across all sectors.

We work closely with our clients to deliver moulds that perform flawlessly — even under demanding production conditions.

Plastic Injection Moulding: The Future Of The Manufacturing Industry?

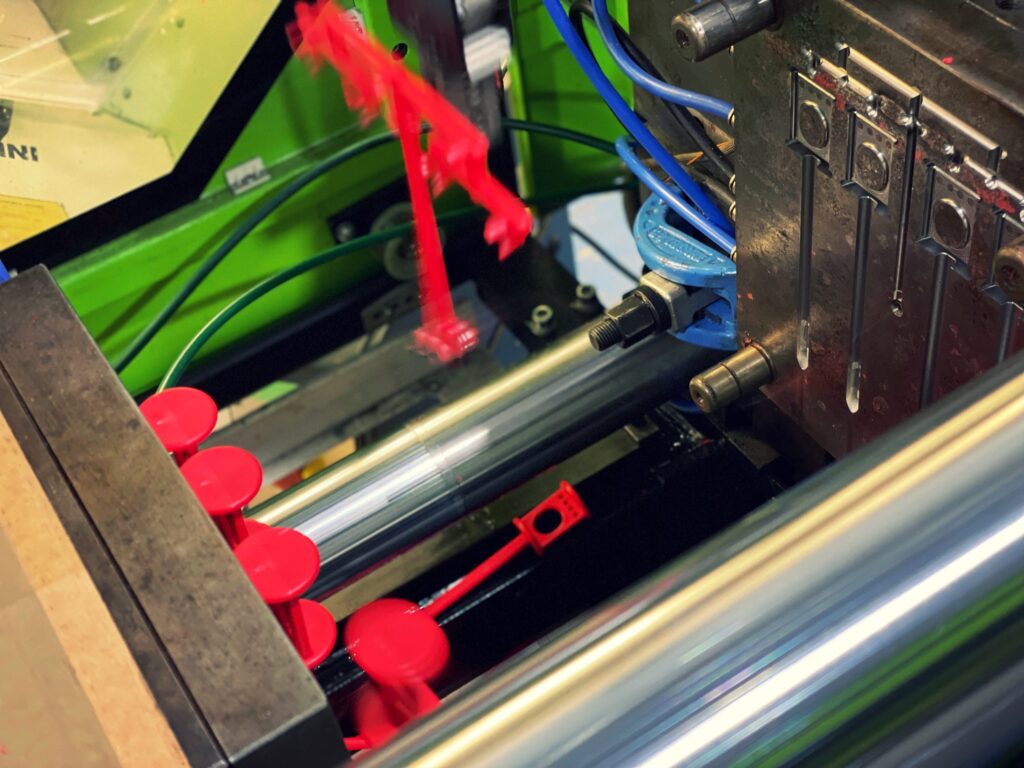

The future of manufacturing is digital, and plastic injection moulding is leading the charge. With innovations like CAD and CAM integration, robotics, and automated quality inspection, today’s moulding processes are faster, more accurate, and more cost-effective than ever.

CAD software allows designers to create precise 3D models of their components. These digital designs are then used by CAM software to generate the machine code required for manufacturing. This digital-to-physical workflow eliminates many traditional errors and dramatically accelerates the production timeline.

Automation now plays a vital role in tasks such as part ejection, mould loading, and in-line inspection. Robotics improve efficiency, reduce waste, and enhance consistency across production runs — all while reducing the need for manual intervention.

This synergy of technology and engineering expertise positions plastic injection moulding as a key player in the future of global manufacturing.

Why Choose Us When You Need Plastic Moulding Companies UK?

Why Choose Us When You Need Plastic Injection Moulding UK?

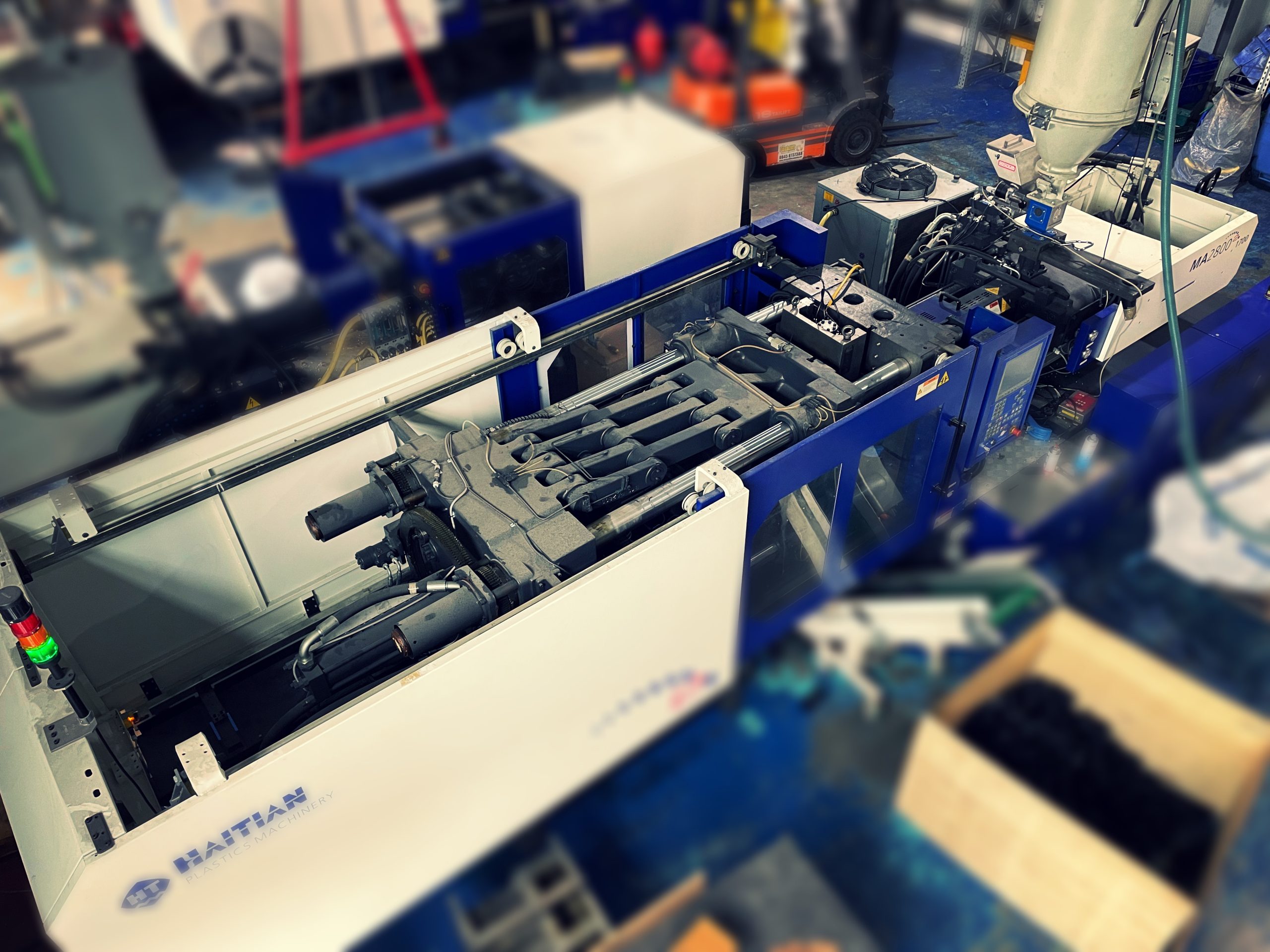

Choosing Bosworth Plastics means gaining access to a team of dedicated plastic injection moulding professionals, all working from our cutting-edge production facility in Leicestershire. From initial design through to delivery, we offer our clients full support and total confidence in the tooling we produce.

We’re proud to provide a comprehensive range of benefits, including:

Innovative Technology

At Bosworth Plastics, we make full use of industry-leading machinery, software, and automated systems to ensure that each mould tool we produce is both accurate and reliable.

Our capabilities allow us to work with a wide range of materials — from commodity plastics to high-performance, engineering-grade polymers — offering maximum versatility for our clients.

Plus, our integration of CAD/CAM technology allows us to turn complex 3D designs into real-world products quickly and efficiently. These tools improve design accuracy, reduce turnaround times, and allow for seamless transitions from digital concepts to physical products. Every part of the process is carefully managed to eliminate errors and enhance performance.

In addition, we are committed to sustainable production practices. By optimising our workflows and minimising material waste, we reduce our environmental impact without compromising on quality.

Meanwhile, our eco-conscious approach reflects our broader responsibility to the planet and aligns with our clients’ growing sustainability goals.

Tailored Services

We understand that every client is different, and every project comes with its own set of unique requirements. That’s why we don’t offer off-the-shelf solutions — we provide tailored mould tooling services designed to meet your specific business and production needs.

Whether you require a one-off prototype, a custom tool for low-volume production, or a fully scalable solution for mass manufacturing, we deliver mould tooling that supports your goals.

Our collaborative process places your needs at the forefront – from day one, our engineers work closely with you to understand your product, your timeline, and your technical requirements.

We also believe in clear communication and close client collaboration throughout every phase of the project. Our goal is to ensure that the finished tooling meets your expectations in both form and function. We’ll keep you informed, involved, and in control!

Our end-to-end solutions include everything from concept development and prototyping to final production and aftercare.

Plus, our customer support team is always available to address any questions or concerns. Your satisfaction is our priority, and we’re committed to ensuring a smooth, stress-free experience.

Quality Assurance

At Bosworth Plastics, quality is at the core of everything we do. To ensure that we meet — and often exceed — client expectations, we operate under ISO-certified quality management systems. These standards guide our entire manufacturing process, from raw material selection through to the final inspection of each tool.

Every mould tool is rigorously tested and inspected to verify its accuracy, durability, and suitability for the intended application. This includes comprehensive checks at each production stage, ensuring consistency and precision every time.

By choosing Bosworth Plastics, you’re investing in a tooling solution that supports long-term performance and repeatable results — critical factors in today’s fast-paced manufacturing landscape.

Cost-Effective Rates

High-quality tooling should also represent excellent value for money. At Bosworth Plastics, we are committed to offering premium services at competitive and transparent prices. We know that manufacturing success depends not just on quality but also on affordability.

Thanks to our efficient processes and ability to scale production, we help you reduce costs without compromising on standards.

By optimising our workflow and minimising downtime, we ensure that our clients get the most from their investment — improving ROI while maintaining the integrity and quality of their final products.

Reliable Timekeeping

We understand that timing is everything in manufacturing. Delays in tooling delivery can create costly disruptions in your production schedule and affect your bottom line. That’s why we take deadlines seriously.

At Bosworth Plastics, we apply structured project management techniques and precise scheduling systems to ensure that your tooling is delivered on time — every time. We build realistic timelines and stick to them, using streamlined workflows and proactive communication to keep projects moving forward efficiently. With Bosworth Plastics as your tooling partner, you can rest assured that your deadlines will be met, helping you maintain your production targets and meet market demand.

Contact Us If You Need Plastic Moulding Companies UK!

At Bosworth Plastics, we are proud to support manufacturers with reliable, high-quality injection mould tooling solutions. Whether you’re launching a new product or upgrading your existing tooling, we have the expertise, facilities, and technology to help you achieve your goals.

Our team is here to make your tooling process smooth, efficient, and successful — from initial concept to production-ready tool. With our customer-focused approach, we put your business at the centre of everything we do.

Ready to get started? Reach out today to book your free consultation and discover how Bosworth Plastics can help deliver your next project.

If You Need Plastic Injection Moulding UK, Make Sure You Contact Us!

Plastic Injection Moulded Product Specialist