Injection Molding Contract Manufacturing

Looking For Injection Molding Contract Manufacturing Services?

Make Sure You Contact Us!

At Bosworth Plastics, we provide top-quality injection molding contract manufacturing services for blue-chip companies across the UK and beyond.

Our team of highly skilled specialists use the latest automated CAD and CAM technology to ensure exceptional results every time, while a commitment to precision, reliability, and professionalism is at the heart of everything we do.

What Is Plastic Injection Molding?

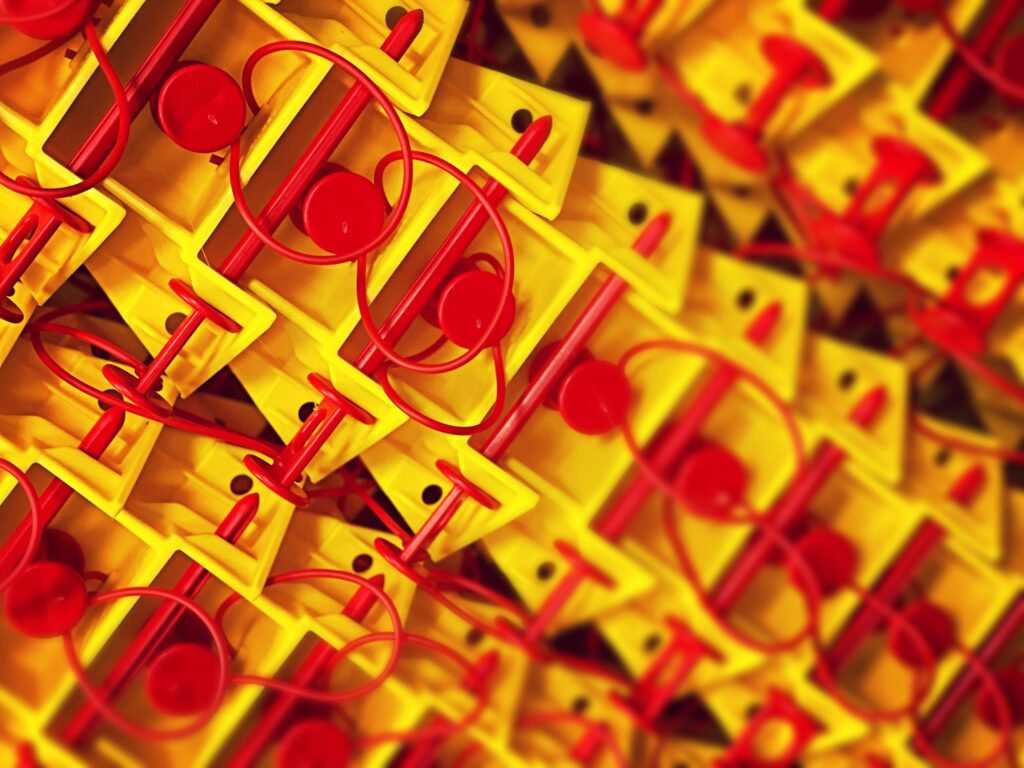

Plastic injection molding is a precise manufacturing method used to create plastic parts and products to exact specifications.

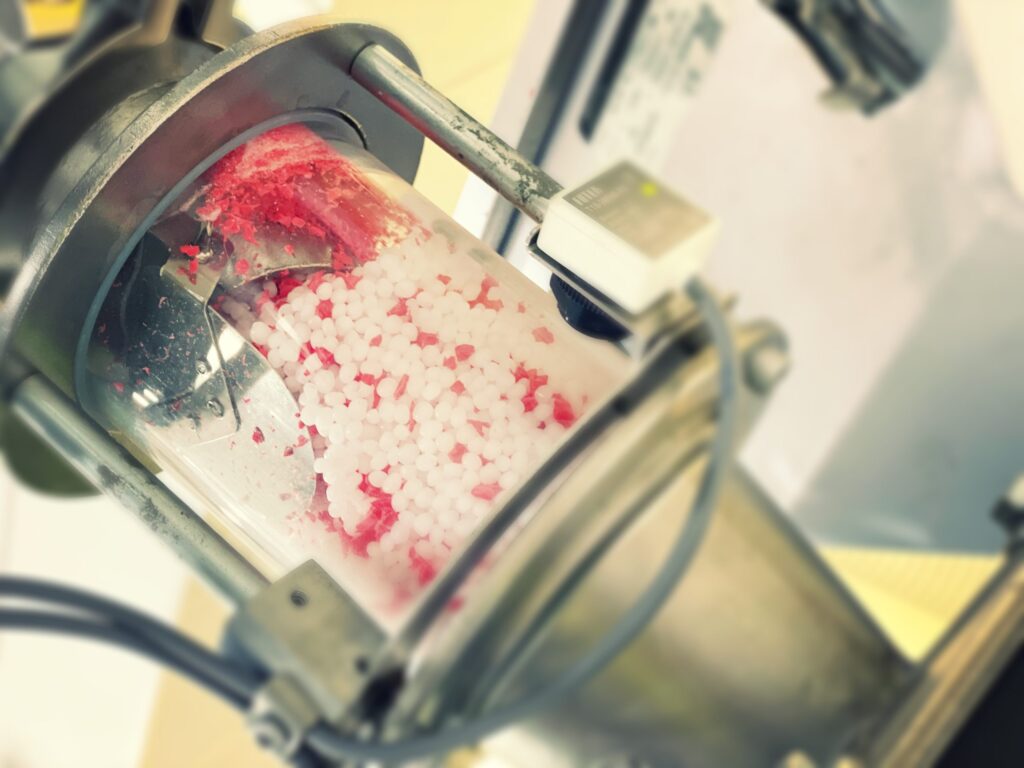

The process starts by melting raw plastic pellets, which are then injected into a pressurised mold. As the plastic cools and hardens, it takes on the shape of the mold, forming the final product.

This advanced technique transforms raw plastic into high-quality finished goods using specialised machinery. It’s widely used across industries to produce a huge variety of plastic components, from small intricate parts to large, durable items.

The Applications Of Plastic Injection Molding

Plastic injection molding is a critical component in the development and manufacturing of nearly all plastic products available on the global market.

Its adaptability makes it suitable for a vast array of industries, including healthcare, automotive, consumer goods, and aerospace. The ability to produce both intricate small parts and larger components with precision has made plastic injection molding indispensable to modern manufacturing.

At Bosworth Plastics, we bring together extensive industry expertise and advanced technology, all governed by stringent quality control protocols. This ensures we consistently deliver high-precision, high-quality results that meet the exacting standards of our clients.

Meanwhile, our team of skilled professionals collaborates seamlessly across all stages of production, ensuring effective communication and reliable knowledge transfer throughout the entire process.

The Future Of The Manufacturing Industry?

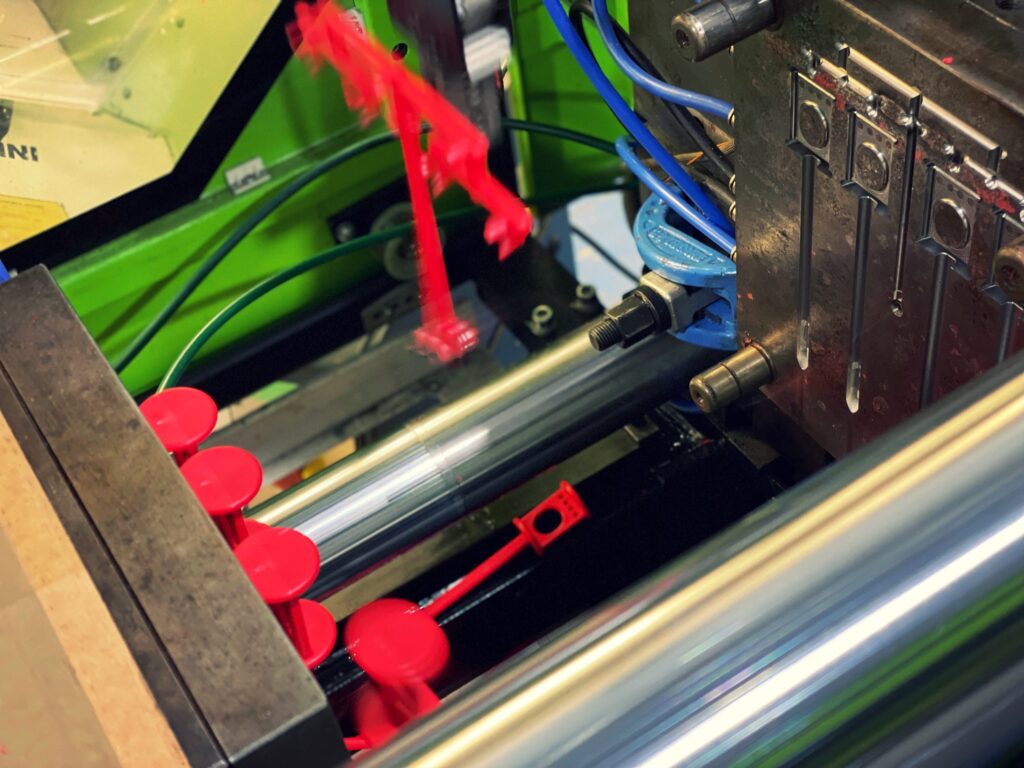

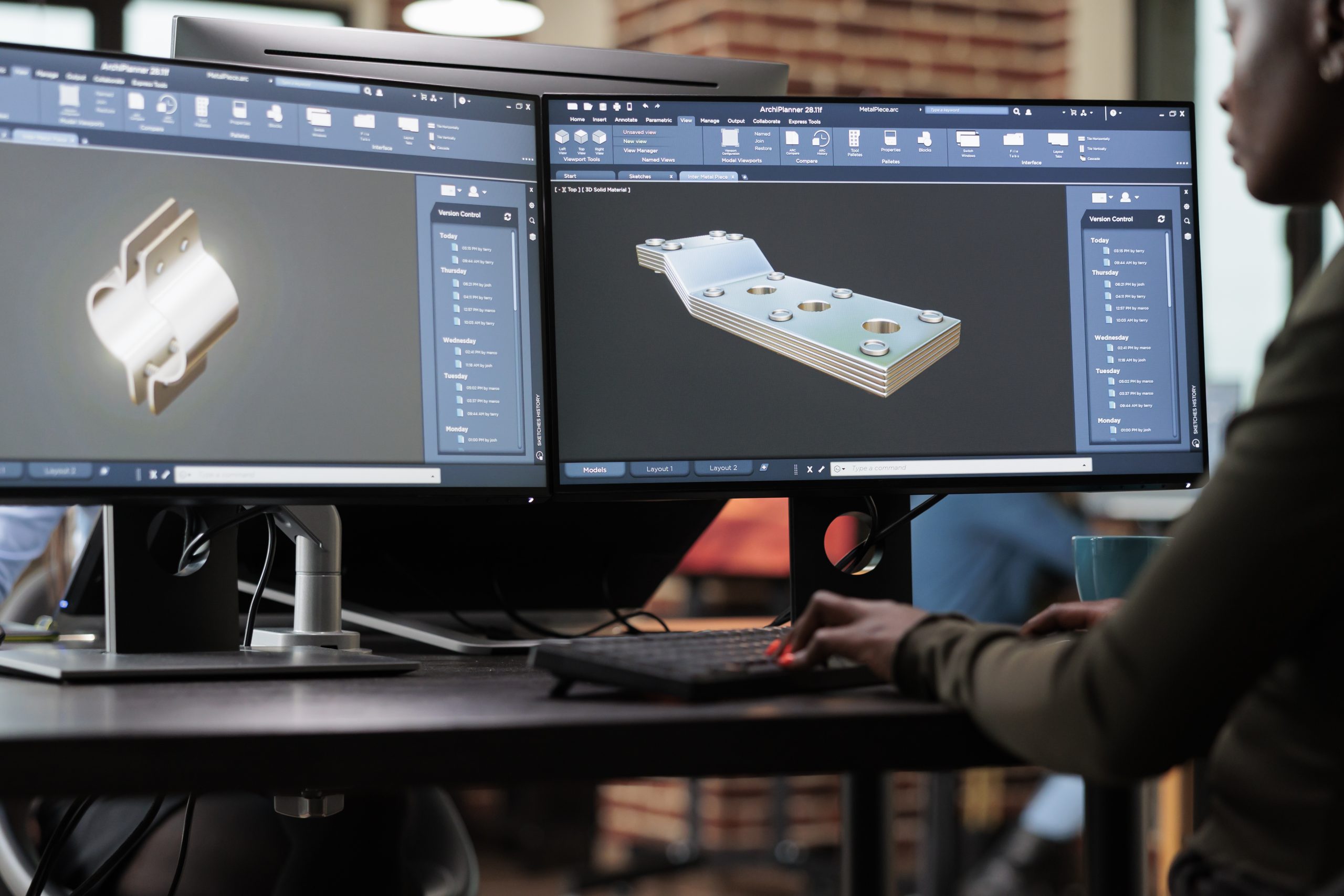

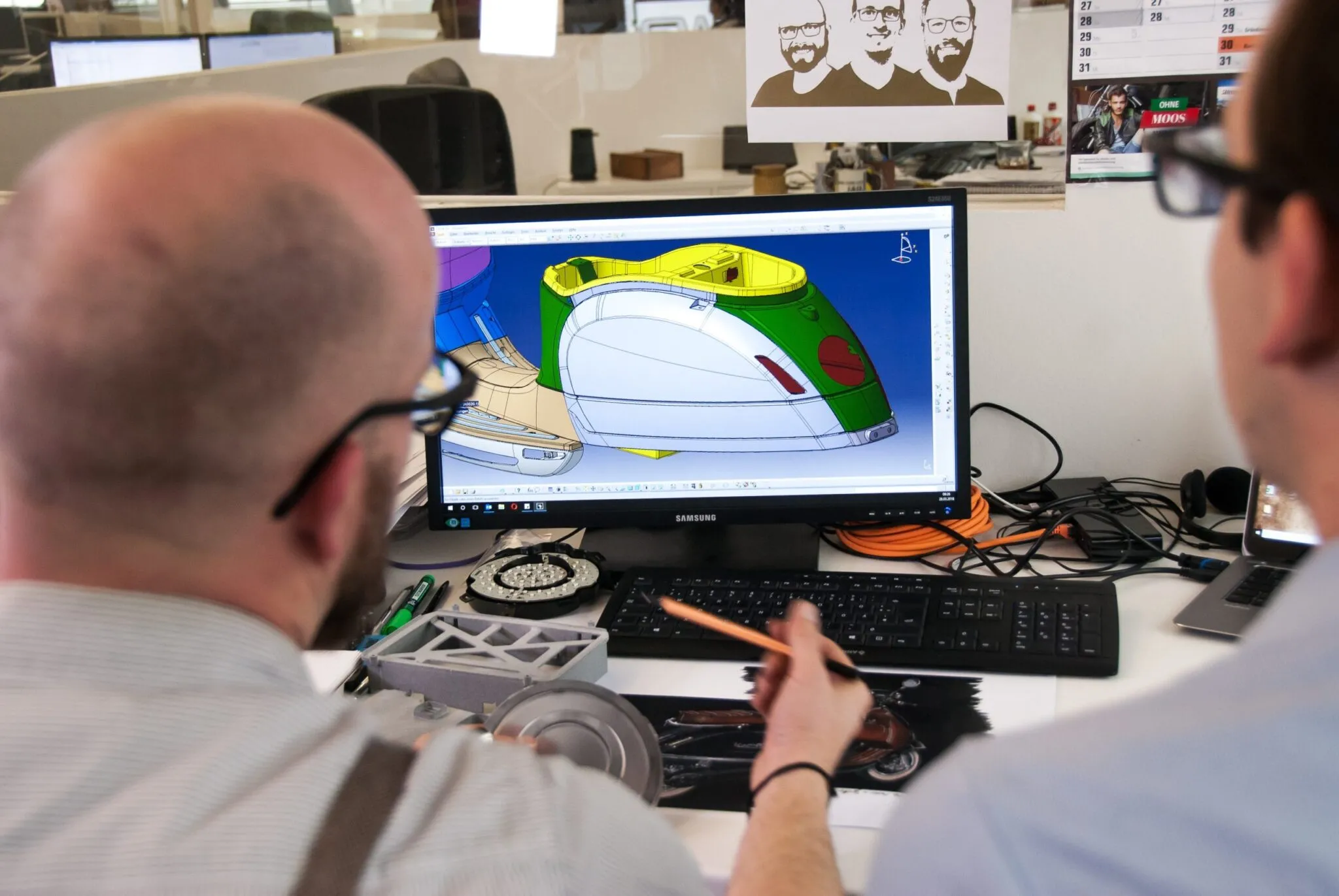

Modern manufacturing has been transformed by advances in technology like computer-aided design (CAD), computer-aided manufacturing (CAM), automation, and robotics.

These tools work together to streamline both product development and production, helping manufacturers achieve greater efficiency, precision, and consistency.

The process typically begins with CAD software, which is used to create detailed 3D models of the product. These designs then feed directly into the CAM system, which translates them into machine-readable instructions—providing a clear, automated workflow from concept to production.

Automation and robotics have further enhanced the plastic injection molding process by speeding up production and maintaining high levels of accuracy. Tasks such as material handling, mold loading, part ejection, and quality inspection can all be carried out quickly and consistently by automated systems.

This reduces the risk of human error, boosts efficiency, and helps maintain exceptional quality across every stage of production.

Why Choose Us For Injection Molding Contract Manufacturing?

When you work with Bosworth Plastics, you’re partnering with a dedicated team of injection molding experts operating from our advanced facility in Leicestershire, UK.

Our clients benefit from decades of industry experience, a commitment to quality, and access to cutting-edge technology designed to meet the demands of modern manufacturing.

Here are just some of the reasons to choose us as your manufacturing partner:

Innovative Technology

At Bosworth Plastics, we leverage the latest manufacturing technologies and equipment to deliver consistently high-quality results.

Whether working with everyday commodity plastics or high-performance polymers, our advanced machinery allows us to create precise tooling across a wide range of materials—ensuring versatility and exceptional accuracy.

We’re also committed to responsible manufacturing. Our processes are designed to minimise waste and reduce environmental impact, helping us meet our sustainability targets without compromising on quality.

Tailored Services

No two projects are the same—and neither are our solutions. We take the time to understand your business and its specific requirements, offering fully tailored services that align with your goals, timelines, and specifications.

Collaboration is at the heart of how we work. Our team partners closely with you throughout the design and development process to ensure the final product reflects your vision and meets all necessary quality standards.

From initial prototypes through to full production, we deliver a seamless experience backed by responsive, professional support every step of the way!

Quality Assurance

Delivering consistent quality is our top priority. That’s why we operate under ISO-certified quality management systems to ensure every mold tool meets the highest industry standards.

Plus, we carry out detailed quality checks at every stage—from selecting the right materials to final inspection—so you can be confident in the reliability and performance of your finished product.

With Bosworth Plastics, you’re investing in precision and reliability!

Cost-Effective Rates

We believe that high quality doesn’t have to mean high cost. That’s because our exceptionally efficient production methods and smart use of resources help us deliver top-tier mold tooling at competitive prices.

By optimising our processes and leveraging economies of scale, we provide cost-effective solutions that support your bottom line—without compromising on performance or reliability.

Reliable Timekeeping

Timely delivery is essential in any project, and we take that responsibility seriously. Through careful project management and streamlined production workflows, we ensure your tooling is delivered on schedule—every time.

With Bosworth Plastics, you can count on dependable lead times and professional execution from start to finish.

Industry-leading Injection Molding Contract Manufacturing

At Bosworth Plastics, we’re here to be your reliable partner in plastic injection mold tooling.

Whether you’re starting with a prototype or gearing up for large-scale production, we have the expertise, technology, and experience to support you at every stage. Our customer-focused approach means you’re always in control—we’ll work closely with you to ensure your goals are met with precision and care.

Have questions or ready to get started? Get in touch with our expert team today to schedule a consultation and receive a free, no-obligation quote!

Plastic Injection Moulded Product Specialist