Injection Molding Automotive

Searching For Top-Quality Automotive Plastic Injection Molding Companies?

Look No Further Than Bosworth Plastics!

As one of the UK’s leading automotive plastic injection molding companies, Bosworth Plastics is proud to deliver premium-quality mold tooling services to our blue-chip clients in the automotive sector.

We hold quality standards, accuracy, and professionalism paramount across all our services, using only highly trained and experienced specialists, alongside cutting-edge automated CAD and CAM technologies.

When you choose Bosworth Plastics, you gain access to the knowledge of our team of plastic injection molding experts, based at our state-of-the-art facilities!

What Is Plastic Injection Molding?

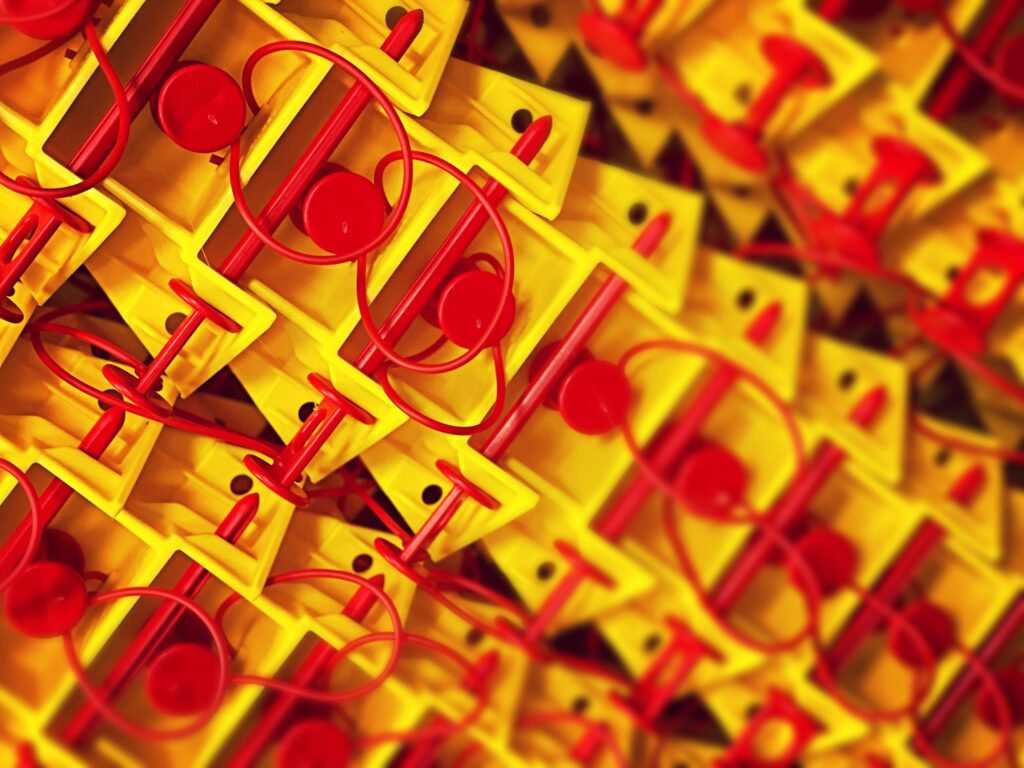

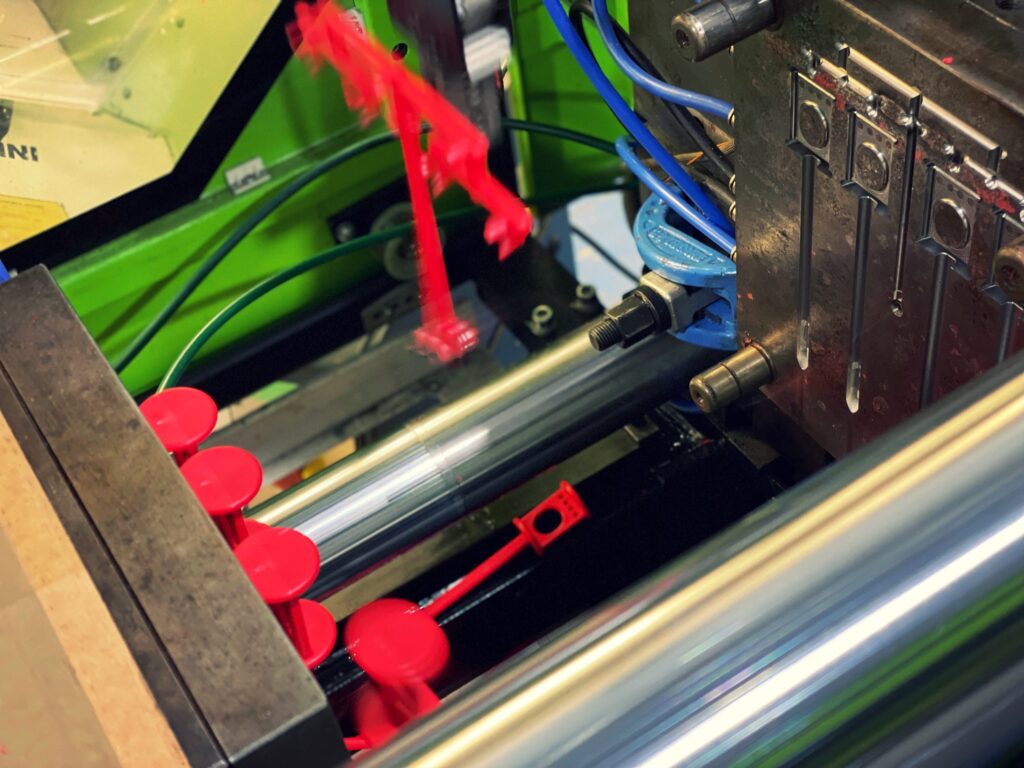

Plastic injection molding is a manufacturing process used to precision-craft plastic parts and products to specification.

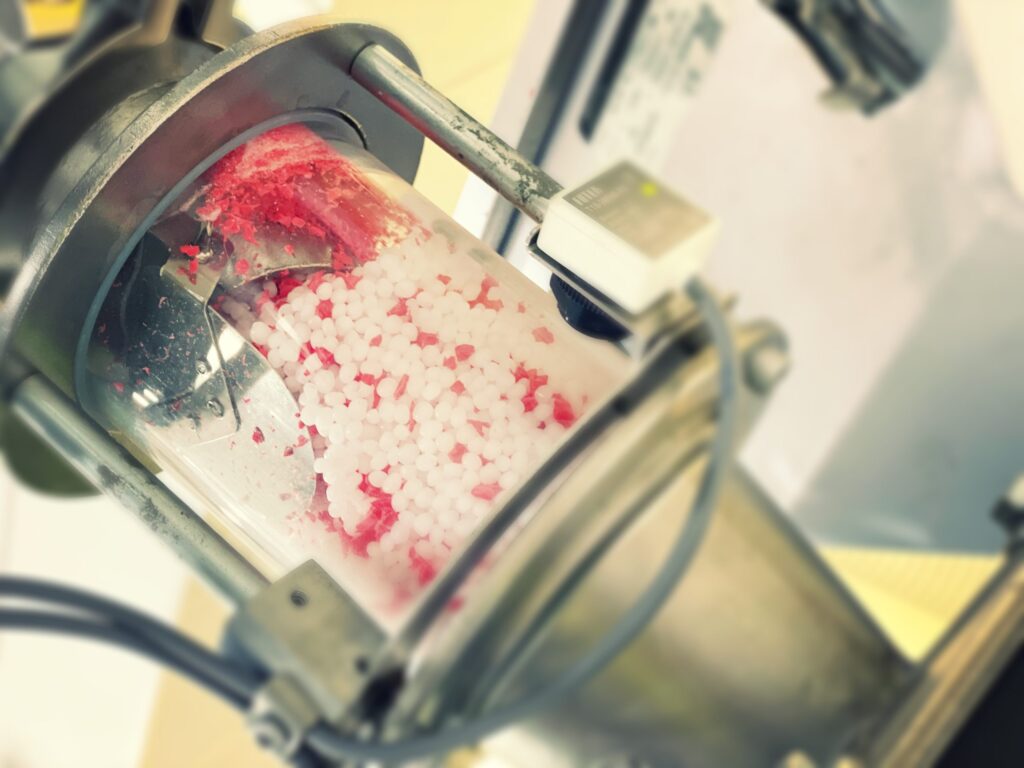

First, the molding process begins by melting the raw plastic pellets. When melted, the plastic is then injected into a pressurised mold cavity, where it cools and hardens, to form the desired shape.

This advanced process turns raw plastic material into finished products, ready for the global market, using specialist machinery. Many industries use this process to make plastic products of various sizes and applications.

The Injection Molding Automotive Applications

Plastic injection molding is used in the product development and manufacturing processes of nearly every plastic product on the global market.

Capable of producing both small and large parts as required, the plastic injection molding process has become indispensable for the automotive manufacturing sector.

At Bosworth Plastics, we are proud to pair a wealth of knowledge and experience with state-of-the-art technology, managed under rigorous quality control standards. This winning combination produces exceptional results for our clients, maintaining high standards of quality and precision in our final products.

Our skilled professionals work collaboratively throughout our processes, ensuring effective communication and information transfer.

The Future Of Automotive Plastic Injection Molding Companies

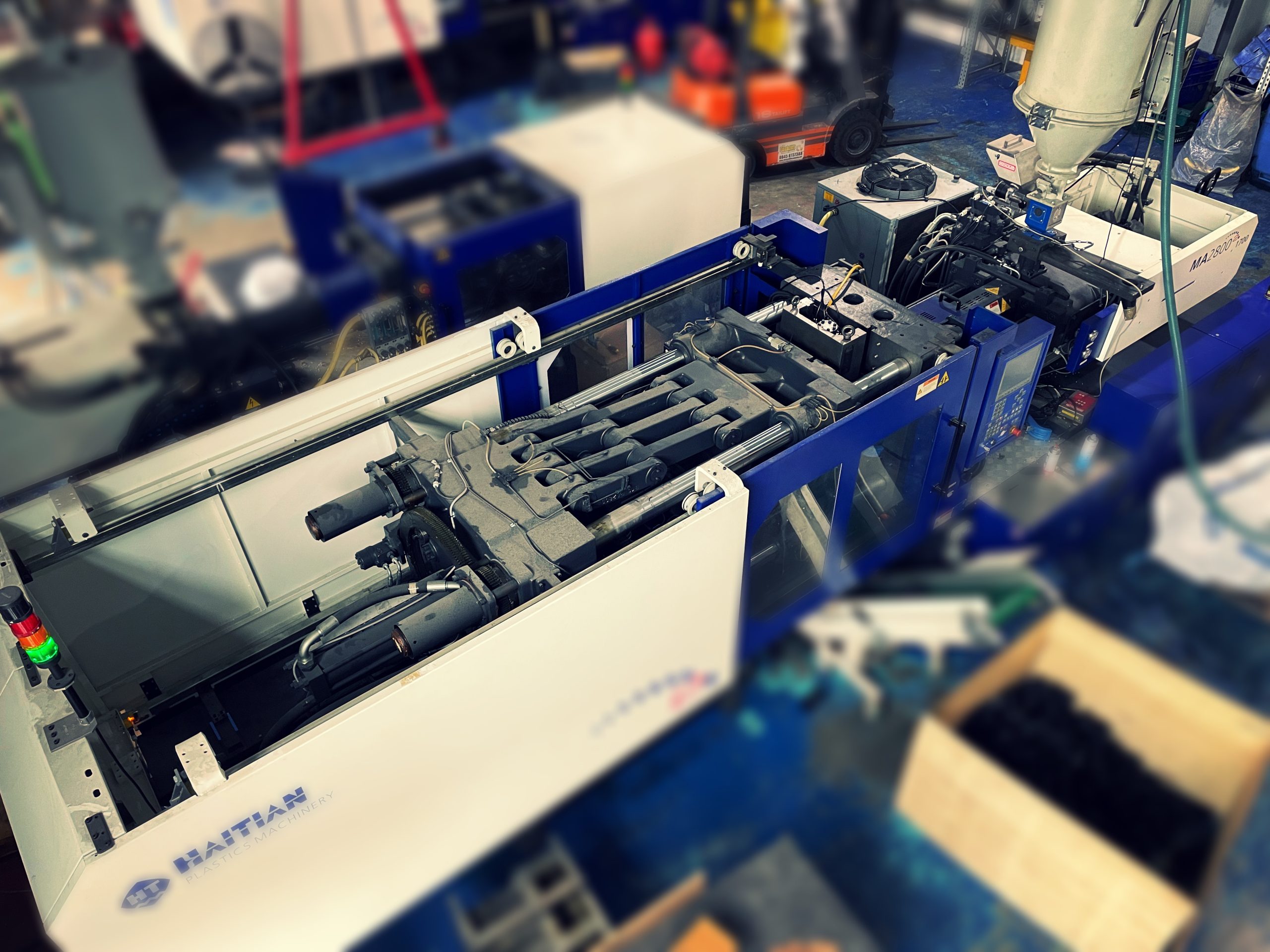

Thanks to the latest technological developments such as computer-aided design (CAD), computer-aided manufacturing (CAM), automation, and robotics, the product development and production processes can now be easily streamlined for enhanced automotive manufacturing.

The two types of computer-aided system are combined to provide comprehensive support. First, the CAD system is used to produce exact 3D designs, which creates a usable blueprint for the product.

The CAM system then uses these designs to produce a set of machine-readable instructions. This guarantees a streamlined manufacturing experience, where accurate results are ensured at all stages of the production process.

In addition, automation and robotics have enabled the plastic injection molding process to produce high-quality results quickly, improving efficiency and speed.

Automated systems are suitable for tasks that demand high levels of accuracy at rapid rates, such as material handling, mold loading, part ejection, and quality inspection. This promotes efficiency while reducing human error.

Why Choose Us?

At Bosworth Plastics, we are your trusted partner for plastic injection mold tooling services. Whatever your requirements, we have you covered, as our customer-centred approach will put you in the driving seat of the manufacturing process!

From the initial prototyping process to large-scale production, we have the skills, experience, and technology required to handle your production needs.

We offer a wide range of benefits to all our clients, such as:

Innovative Technology

At Bosworth Plastics, we harness cutting-edge technology and equipment to support our services, ensuring that they meet the strictest of automotive industry standards.

From commodity plastics to high-performance polymers, our machines are capable of crafting tooling using a diverse range of raw materials, delivering versatile capabilities and exceptional accuracy.

We minimise our waste and environmental impact throughout our production processes, ensuring we meet our sustainability goals.

Tailored Services

We understand that no two clients are the same.

That’s why, when you choose Bosworth Plastics, you will be provided with services that are specifically tailored to your business’ requirements. We offer custom solutions that meet your project goals and specifications, ensuring that you always get what you need from us.

In addition, we believe that communication and collaboration are essential to ensuring high-quality results. Therefore, our team of plastic injection mold tooling specialists will work in collaboration with you, putting you front and centre of their design process.

This ensures that your finished mold tool aligns precisely with your vision – and with the quality control standards necessary to create an exceptional product.

Meanwhile, our comprehensive solutions span all phases of our production process from prototyping to production, complimented by our exceptional customer support services.

We are always open to any feedback you may have, and in the unlikely event that you have any concerns or queries, will do our utmost to resolve them quickly and effectively.

Quality Assurance

Quality assurance is held paramount to ensure customer satisfaction with the standard of our tooling. At Bosworth Plastics, we use ISO-certified quality management systems to ensure effective quality assurance throughout our manufacturing processes. This ensures that each finished tool meets the high standards of our prestigious clientele.

Using rigorous quality control checks throughout our production process, from material selection to final inspection, we are committed to ensuring exceptional quality standards every time. When you choose Bosworth Plastics, you can be sure you’ll receive top-quality products with every order!

Cost-Effective Rates

At Bosworth Plastics, we understand that in order to sell, products need not only to be high-quality, but also retailed at a marketable price. That’s why we ensure our high-quality services are delivered at reasonable rates.

Using efficient production processes and economies of scale, our cost-effective solutions enable you to increase your ROI while maintaining your quality standards.

Reliable Timekeeping, Every Time

We understand that effective timekeeping is critical for ensuring your professional reputation.

At Bosworth Plastics, we are committed to maintaining strict manufacturing schedules, using rigorous project management and streamlined production processes to get your project finished on time, every time.

Choose us for reliable services from expert professionals!

If You’re Looking For Top-Quality Automotive Plastic Injection Molding Companies, Make Sure You Contact Us!

If You’re Looking For Top-Quality Injection Molding Automotive Companies, Make Sure You Contact Us!

Plastic Injection Moulded Product Specialist