Bespoke Plastic Mouldings

Need Top-Quality Bespoke Plastic Mouldings?

Look No Further Than Bosworth Plastics!

At Bosworth Plastics, we lead the way in providing bespoke plastic mouldings for discerning British businesses. Our commitment to staying at the forefront of innovation is reflected in the continuous updates to our processes, incorporating the latest advancements in CAD, CAM, and automated technologies. This proactive approach enables us to offer quick turnaround timescales, cost efficiency, and premium-quality products to our valued clientele.

In our dedication to innovation, we embark on extensive research and development initiatives. Collaborating with industry experts, we leverage cutting-edge technologies to foster continuous learning, growth, and development across the organisation.

This ensures that our clients not only receive an exceptional standard of service, but also achieve prestigious results that surpass their expectations.

What Is Plastic Injection Moulding?

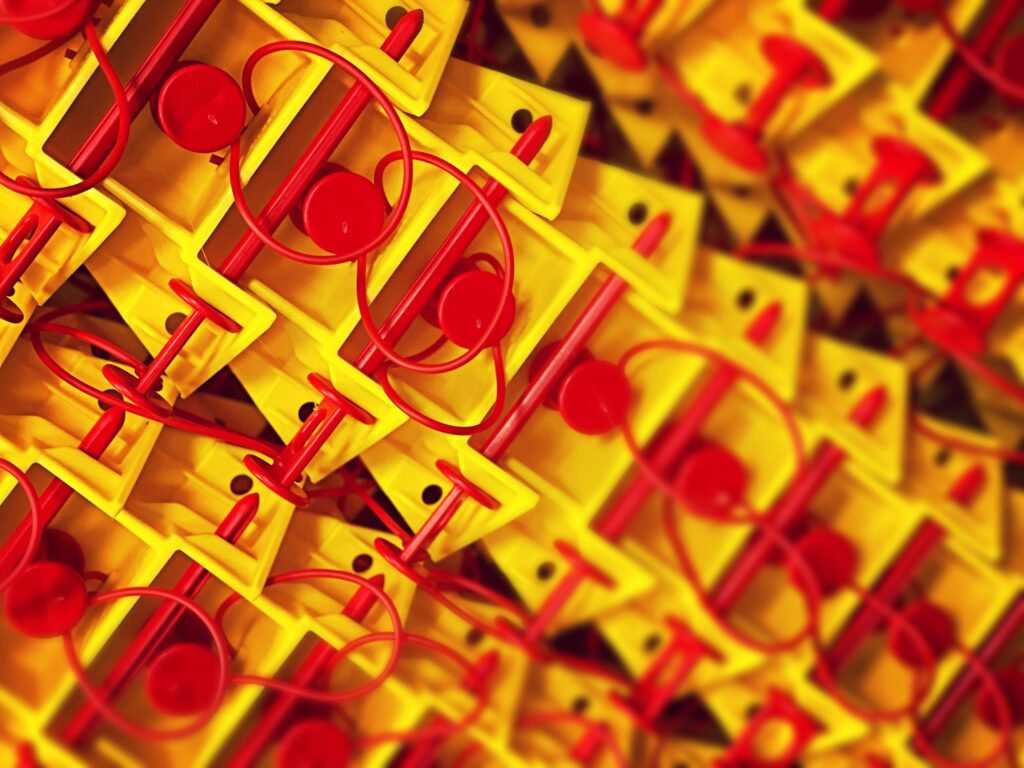

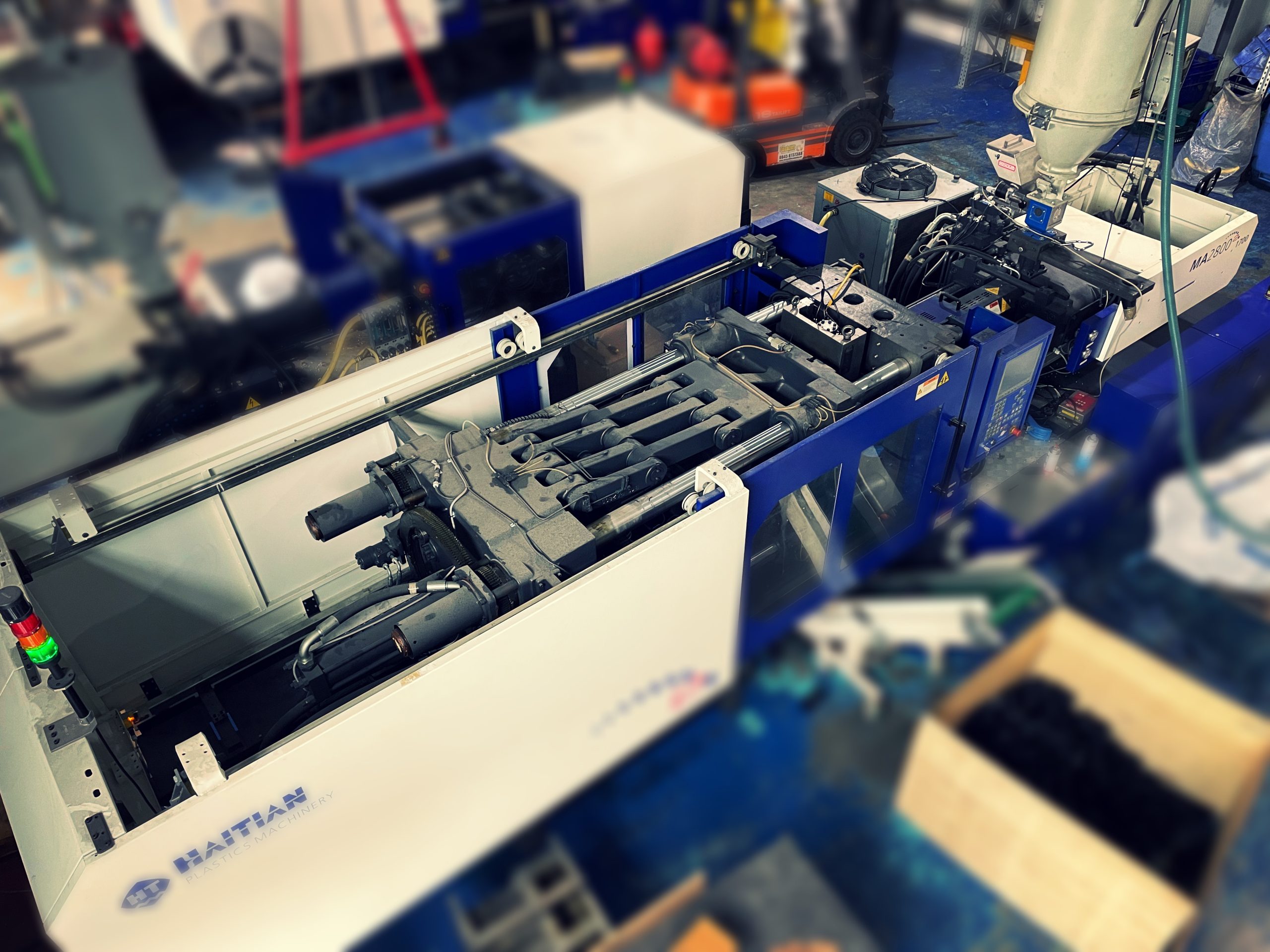

Plastic injection moulding is an advanced manufacturing technique employed to craft high-quality plastic parts and products with precision. This intricate process utilises specialised machinery and moulds to transform raw plastic material into fully finished, market-ready products.

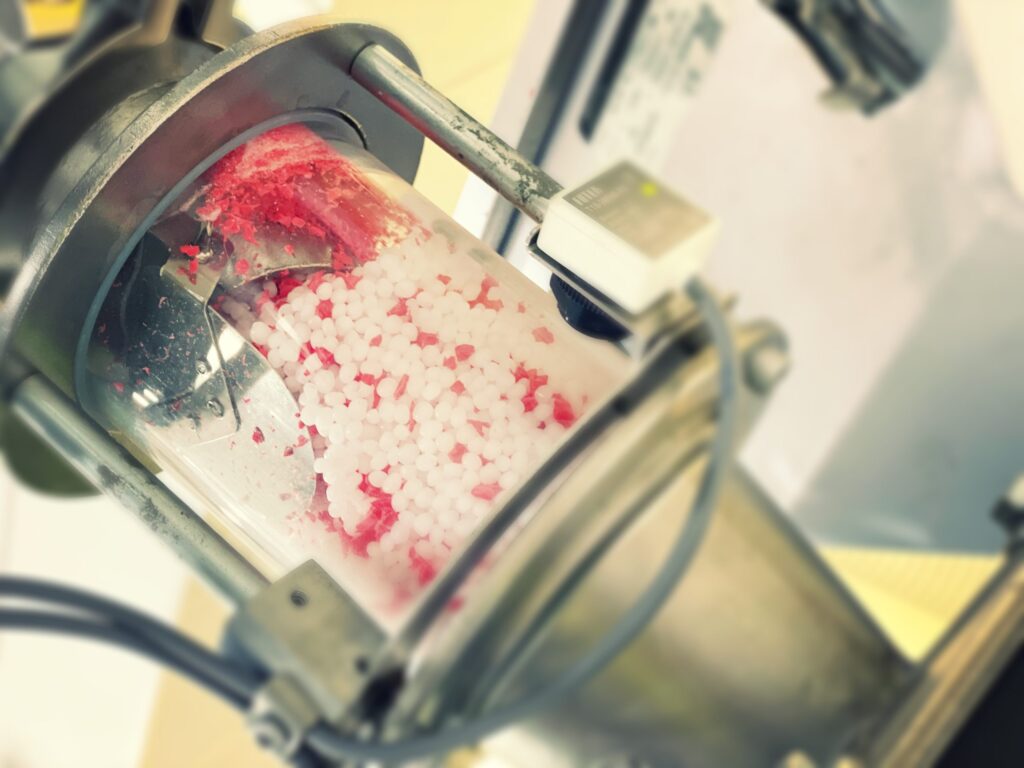

Now, let’s delve into how it operates. Initially, plastic pellets undergo melting and are then injected into a pressurised mould cavity. Within the mould, the plastic cools and hardens, taking on the specified shape.

Widely adopted across numerous industries, this method caters to a diverse array of applications and product sizes.

Which Sectors Use Bespoke Plastic Mouldings?

Due to its versatility across a wide range of sectors, plastic injection moulding emerges as a key player in developing virtually any product in today’s marketplace.

Industries routinely employing plastic injection moulding processes encompass automotive, aerospace, healthcare, consumer goods, and electronics.

Here at Bosworth Plastics, we integrate cutting-edge technology and superior craftsmanship into our manufacturing processes.

Our commitment revolves around prioritising quality control throughout our operations, with our skilled professionals working collaboratively to ensure excellence and precision in our finished products.

The Future Of Manufacturing?

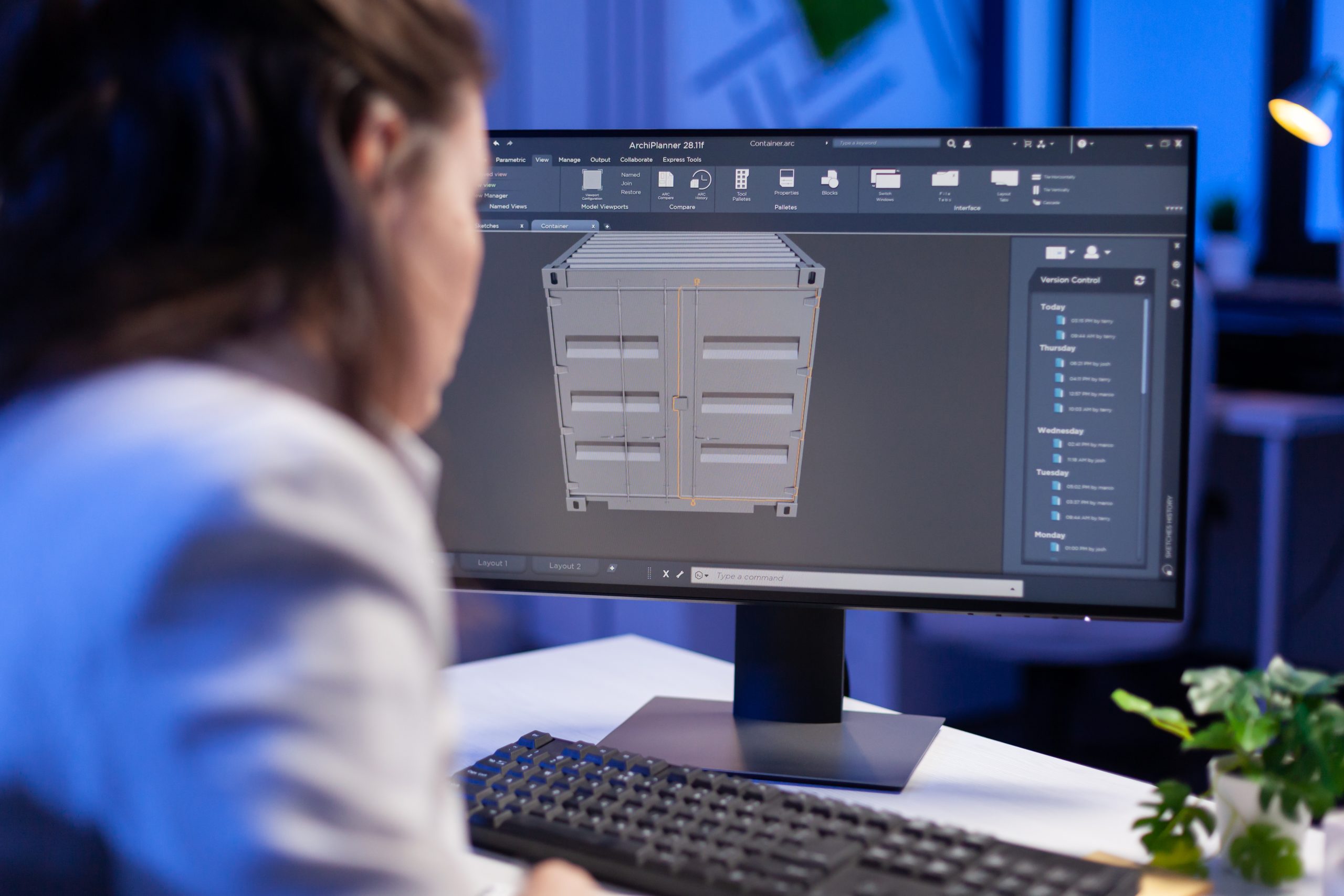

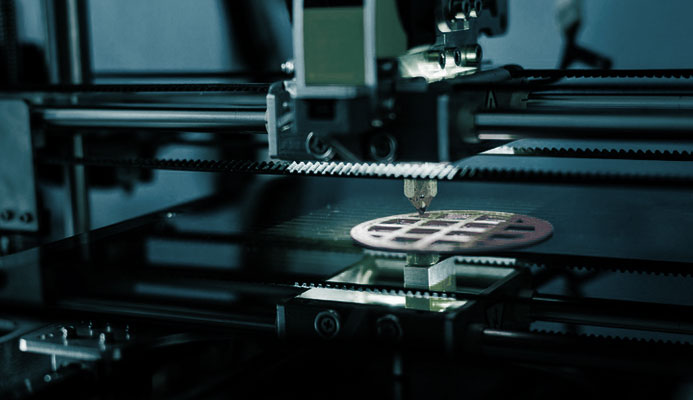

Plastic injection moulding integrates cutting-edge technology, embracing the latest advancements such as computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, alongside automation and robotics. This amalgamation enhances both product development and production processes.

Working together, CAD and CAM systems each play distinct but equally significant roles. CAD technology takes the lead, creating detailed 3D designs with high precision, providing manufacturers with an accurate and well-defined blueprint for the final product.

Following this, CAM systems translate these intricate designs into machine-readable instructions. This simplifies the manufacturing process, fostering standards of accuracy and precision throughout.

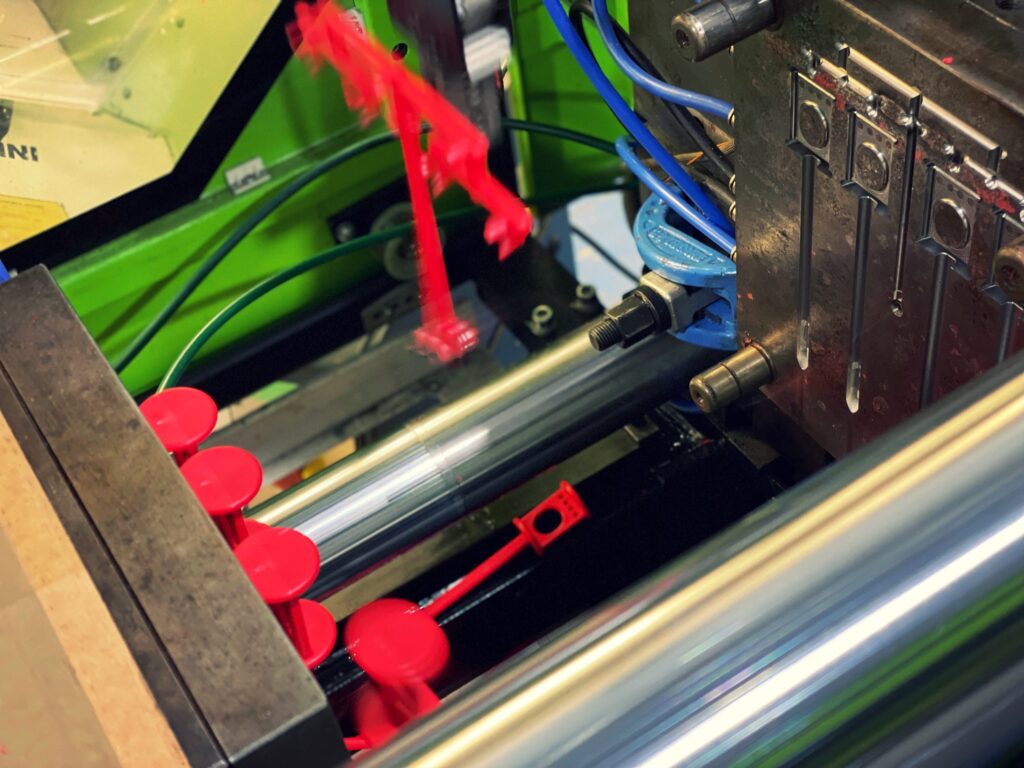

The efficiency of plastic injection moulding has been significantly heightened by the contributions of automation, Artificial Intelligence, and robotics.

Automated systems excel in tasks requiring exceptional accuracy and speed, such as material handling, mould loading, part ejection, and quality inspection.

This not only enhances productivity but also reduces the margin of error, ensuring exceptional results every time.

Why Choose Us?

At Bosworth Plastics, we take great pride in offering industry-leading plastic injection mould tooling services tailored for the UK’s manufacturing sector. Our commitment revolves around delivering exceptional quality standards, precision, and professional expertise to our esteemed clientele.

Our cutting-edge facilities house state-of-the-art CAD, CAM, and automated technologies, operated by a highly trained and experienced team of plastic injection moulding specialists.

Our services come with a myriad of benefits, including:

Plastic Injection Moulding Expertise

Recognising that innovation demands a wealth of industry expertise, our operations are informed by the knowledge and experience of our team of industry experts.

Whether it’s custom mould tooling, intricate components, or high-volume production, we possess the expertise to deliver high-quality results.

With extensive experience across various industries – from automotive and aerospace to medical devices and consumer electronics – we can meet all your plastic injection mould tooling needs to an exceptional standard.

Cutting Edge Technology

We ensure compliance with even the most rigorous industry standards through leveraging state-of-the-art technology.

Our machines can craft tooling using a wide range of raw materials, from commodity plastics to high-performance polymers, ensuring superior versatility and precision in all your projects.

In addition, our commitment to sustainability principles guides us to minimise waste and environmental impact at every stage of the manufacturing process.

Custom Solutions

Understanding the uniqueness of every project, we adopt a tailored approach, offering custom solutions according to your needs and specifications.

Our team of experienced engineers and designers collaborates with you, prioritising a customer-centred approach to ensure that your mould tool aligns with your vision and meets stringent quality standards.

We offer a comprehensive solution to your mould tooling needs, from prototyping to production, with exceptional customer support throughout the process.

Quality Assurance

Quality remains paramount throughout our manufacturing processes. That’s why we utilise ISO-certified quality management systems to ensure that every tool we produce measures up to our clients’ standards.

Our dedication to quality is demonstrated through rigorous quality control checks throughout our production process, from material selection to final inspection.

You can trust us to deliver superior quality products that withstand the test of time!

Competitive Pricing

Recognising the importance of cost-effectiveness, we offer customers the benefits of premium-quality production at reasonable rates.

Our cost-effective solutions leverage efficient production processes and economies of scale, allowing you to maximise your ROI while maintaining the quality of your products.

On Time, Every Time

We understand that staying on schedule is essential for achieving and maintaining a professional reputation for your business.

Our streamlined production processes, coupled with rigorous project management, ensure that your orders are consistently delivered on time, and in perfect condition.

Customer-Centred Services

Putting our clients first, we take pride in collaborative work and remain open to feedback or concerns regarding your product development.

Our customer support team is dedicated to assisting you throughout your journey with us, ensuring you derive the utmost value from our services.

Get In Touch!

At Bosworth Plastics, we are your reliable partner for plastic injection mould tooling services. Whether you’re dealing with small prototypes or engaging in large-scale production, we possess the expertise and extensive resources to meet your production needs.

Interested in discussing your project? Take the next step and schedule a consultation with our expert team today.

If You’re Looking For Top-Quality Bespoke Plastic Mouldings, Make Sure You Contact Us!

Plastic Injection Moulded Product Specialist