Custom Injection Molding Companies

Looking For Top-Quality Custom Injection Molding Companies?

Look No Further Than Bosworth Plastics!

At Bosworth Plastics, we are proud to be one of the UK’s leading custom injection molding companies, helping businesses across the UK bring their ideas to life with precision and quality. We’re always innovating, continuously updating our processes with the latest in CAD, CAM, and automation to deliver faster turnaround times, cost-effective solutions, and top-tier products.

Innovation drives everything we do. Through ongoing research and development, we work with industry experts to stay ahead of the curve, embracing new technologies that improve our capabilities and keep us growing.

For our clients, this means more than just great service—it means exceptional results that exceed expectations!

What Is Plastic Injection Molding?

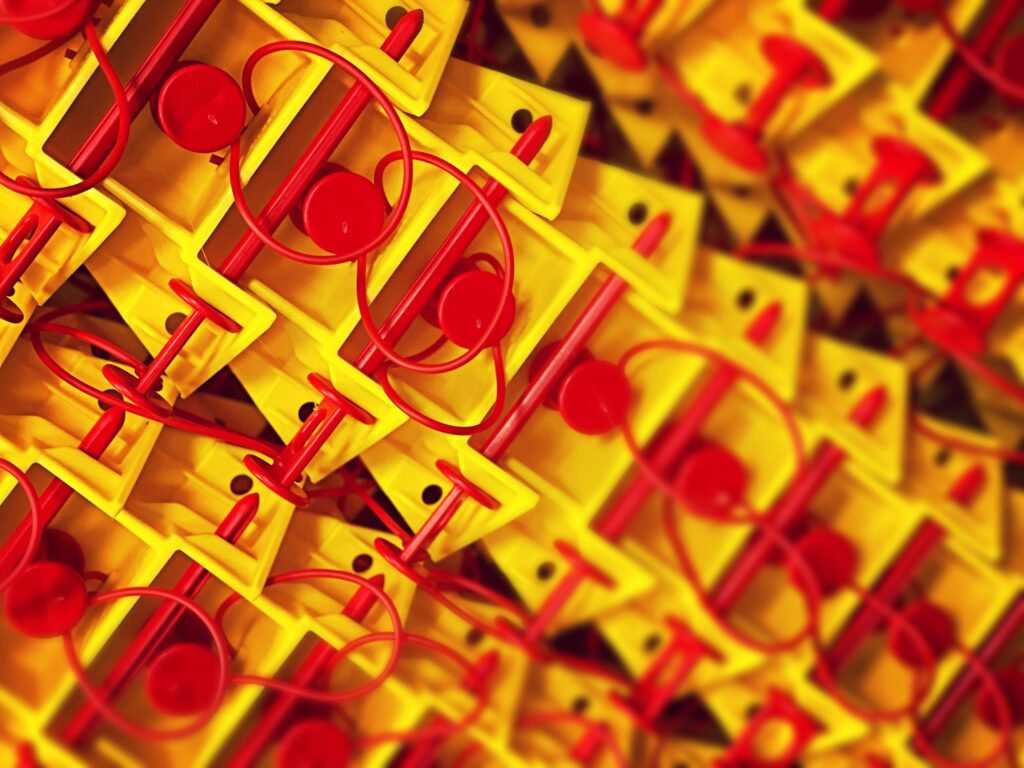

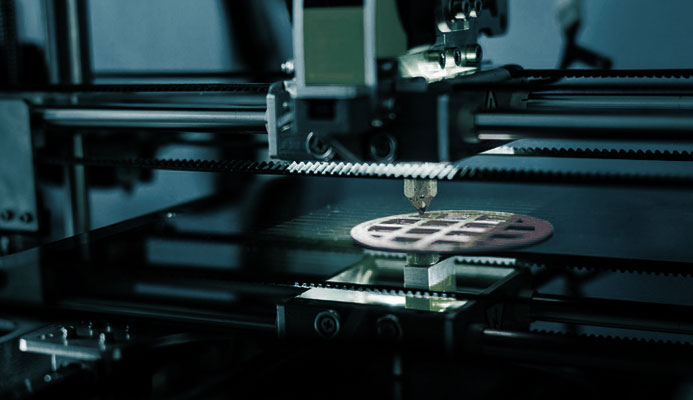

Plastic injection molding is a highly efficient way to produce precise, high-quality plastic parts and products.

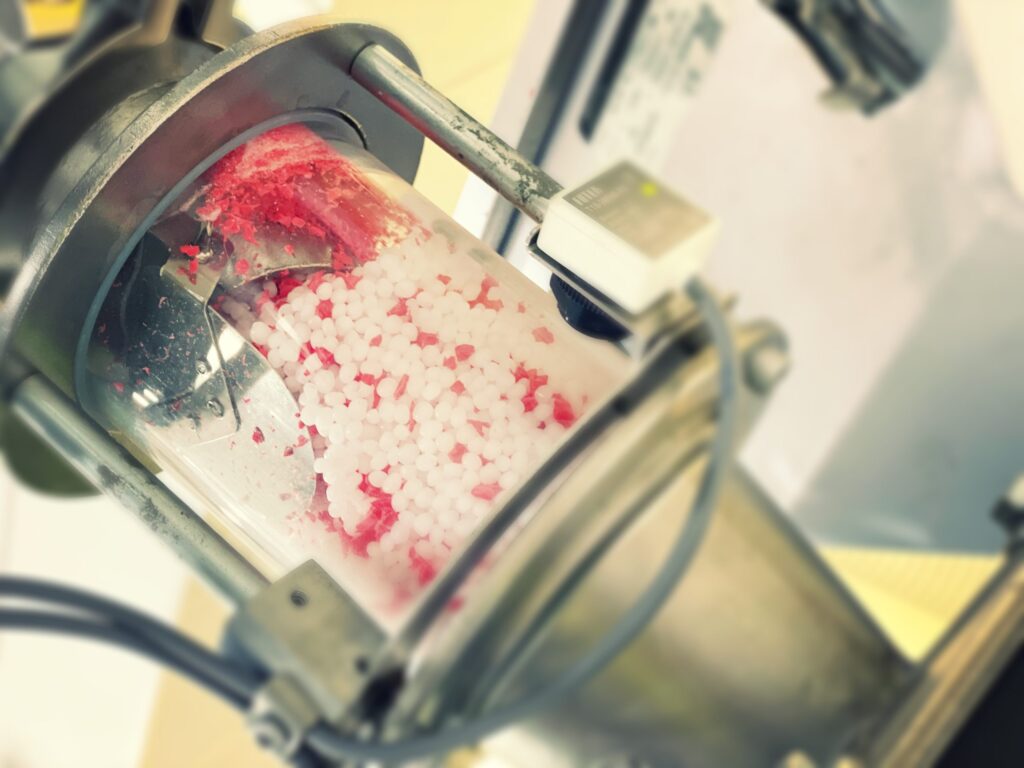

It works by melting plastic pellets and injecting the liquid material into a mold under pressure. As the plastic cools and hardens, it takes on the exact shape of the mold, creating a finished product ready for use.

This process is widely used across industries, from automotive and aerospace to healthcare and consumer goods, making everything from small intricate components to large durable parts.

Its versatility and accuracy make it a reliable manufacturing method for countless applications.

Which Sectors Use Plastic Injection Molding?

Plastic injection molding is a vital manufacturing process used across countless industries, from automotive and aerospace to healthcare, consumer goods, and electronics. Its versatility makes it essential for creating everything from small, intricate components to large, durable parts.

At Bosworth Plastics, we combine advanced technology with industry-leading craftsmanship to deliver high-quality results.

Excellence is at the heart of everything we do, with our expert team working together to ensure every product meets the highest standards of precision.

The Future Of Manufacturing?

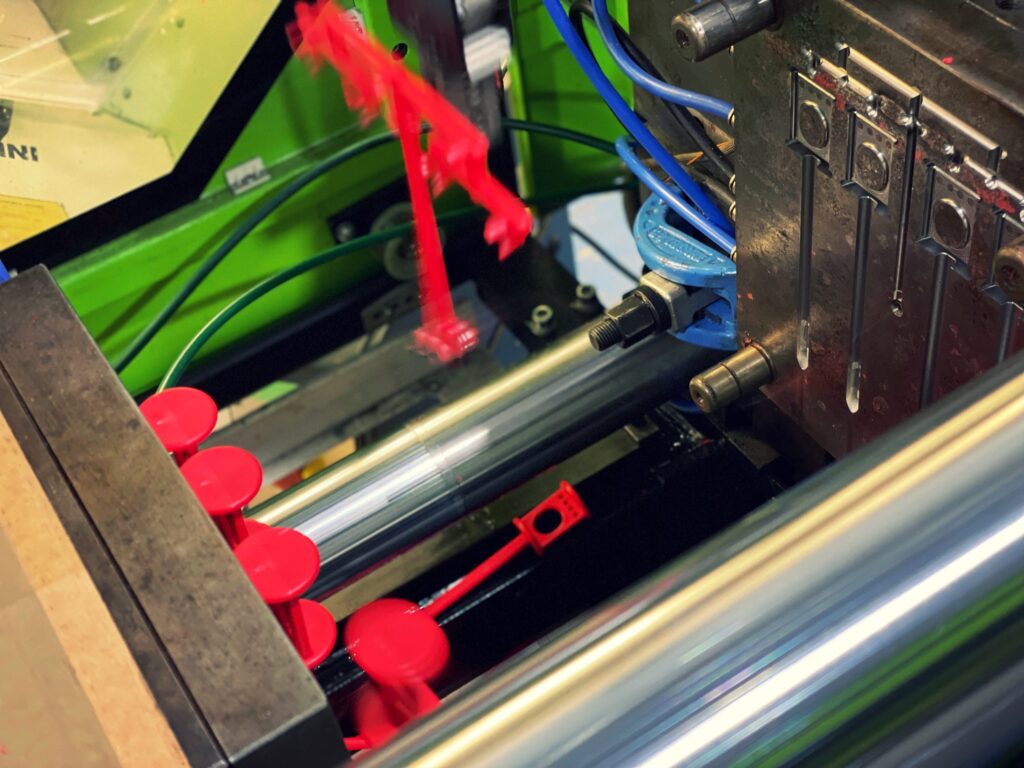

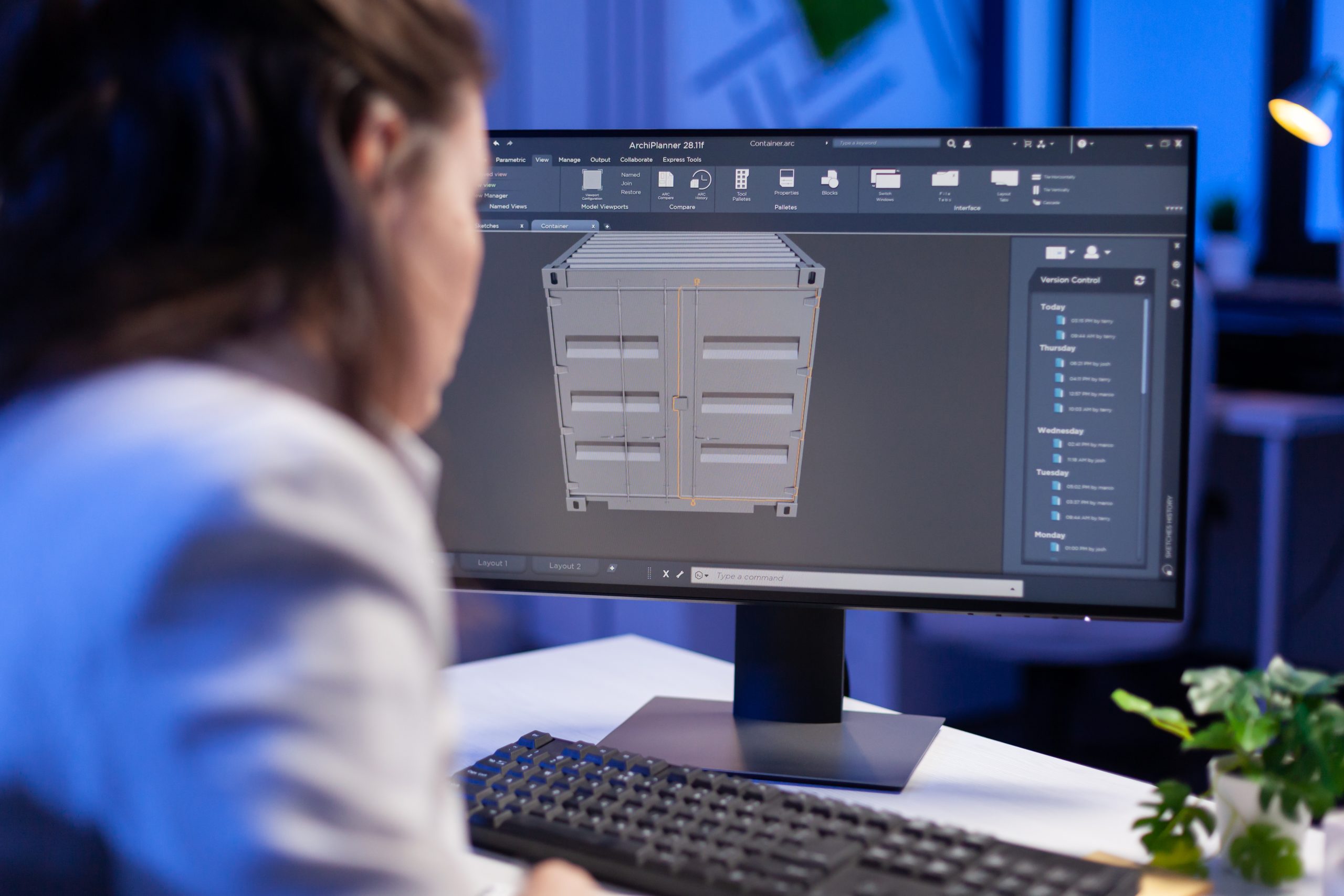

In recent times, plastic injection molding has evolved to incorporate computer-aided design (CAD), computer-aided manufacturing (CAM), automation, and robotics. These advancements have transformed both product development and production, making the process faster, more precise, and highly efficient.

CAD plays a key role in the early stages, creating detailed 3D designs that serve as an exact blueprint for the final product. CAM then takes over, converting these designs into machine-readable instructions that guide the manufacturing process with pinpoint accuracy.

Automation and robotics further enhance efficiency by handling tasks like material loading, mold operation, part ejection, and quality checks. This not only speeds up production but also ensures consistency, thereby reducing errors and delivering high-quality results every time.

Why Choose Us If You’re Looking For Custom Injection Molding Companies?

At Bosworth Plastics, we take pride in offering industry-leading plastic injection mold tooling services designed specifically for the UK manufacturing sector. Our focus is on delivering exceptional quality, precision, and professional expertise to meet the needs of our valued clients.

Our state-of-the-art facilities are equipped with the latest CAD, CAM, and automated technologies, all operated by a skilled team of plastic injection molding specialists.

Here’s what we can offer:

Plastic Injection Molding Expertise

Innovation requires deep industry knowledge, and our team is packed with experts who bring years of experience to every project.

Whether you’re looking for custom mold tooling, intricate components, or high-volume production, we have the expertise to deliver outstanding results.

From automotive and aerospace to medical devices and consumer electronics, we have the experience to meet your mold tooling needs to the highest standards.

Cutting Edge Technology

We use the latest technology and equipment to ensure we meet even the most stringent industry standards.

Our machines can handle a wide range of raw materials, from standard plastics to high-performance polymers, giving you flexibility and precision for every project.

We also prioritise sustainability, aiming to reduce waste and minimise environmental impact at each stage of the process.

Custom Solutions

Every project is unique, which is why we offer tailored solutions to meet your specific needs.

Our experienced engineers and designers work closely with you to ensure that your mold tool is designed to your exact specifications and meets rigorous quality standards.

From prototyping to production, we offer comprehensive solutions with exceptional customer support along the way!

Quality Assurance

Quality is at the core of everything we do. We follow ISO-certified quality management systems to ensure every mold tool we produce meets your standards.

Our rigorous quality control checks cover everything from material selection to final inspection, so you can rely on us to deliver durable, high-quality products that stand the test of time.

Competitive Pricing

We understand the importance of keeping costs in check without sacrificing quality.

By streamlining our production processes and taking advantage of economies of scale, we offer cost-effective solutions that help you maximise your return on investment while maintaining product excellence.

On-Time Delivery

Meeting deadlines is crucial, and we’re committed to delivering your orders on time and in perfect condition.

Our efficient production processes, combined with effective project management, ensure that your products are always delivered as promised.

Customer-Centred Services

We put our clients first, fostering a collaborative approach and staying open to feedback throughout the development process. Our dedicated customer support team is always available to assist, ensuring you get the most out of our services and achieve the best possible results for your project.

At Bosworth Plastics, we’re more than just a supplier—we’re a trusted partner in bringing your ideas to life with precision and quality!

Get In Touch!

At Bosworth Plastics, we’re here to be your trusted partner for all your plastic injection mold tooling needs. Whether you’re working on small prototypes or large-scale production, we have the expertise and resources to support your project every step of the way.

Ready to get started? Give us a call!

If You’re Looking For Top-Quality Custom Injection Molding Companies, Make Sure You Contact Us!

Plastic Injection Moulded Product Specialist