Custom Plastic Injection Molder

Need A Top-Quality Custom Plastic Injection Molder?

Look No Further Than Bosworth Plastics!

At Bosworth Plastics, we are a highly trusted custom plastic injection molder for blue-chip companies working in vital industries throughout the UK.

Our dedication to excellence drives us to continuously refine our processes by integrating the latest developments in CAD, CAM, and automation into our workflow, keeping us at the cutting edge of innovation. This forward-thinking approach allows us to offer fast lead times, cost efficiency, and exceptional product quality to all our clients.

We’re committed to ongoing innovation through extensive research and development; by embracing advanced technologies and working closely with industry experts, we promote a culture of continuous learning, growth, and progress throughout our organisation. This enables us to deliver a level of service that not only meets – but exceeds – our clients’ expectations.

What Is Plastic Injection Molding?

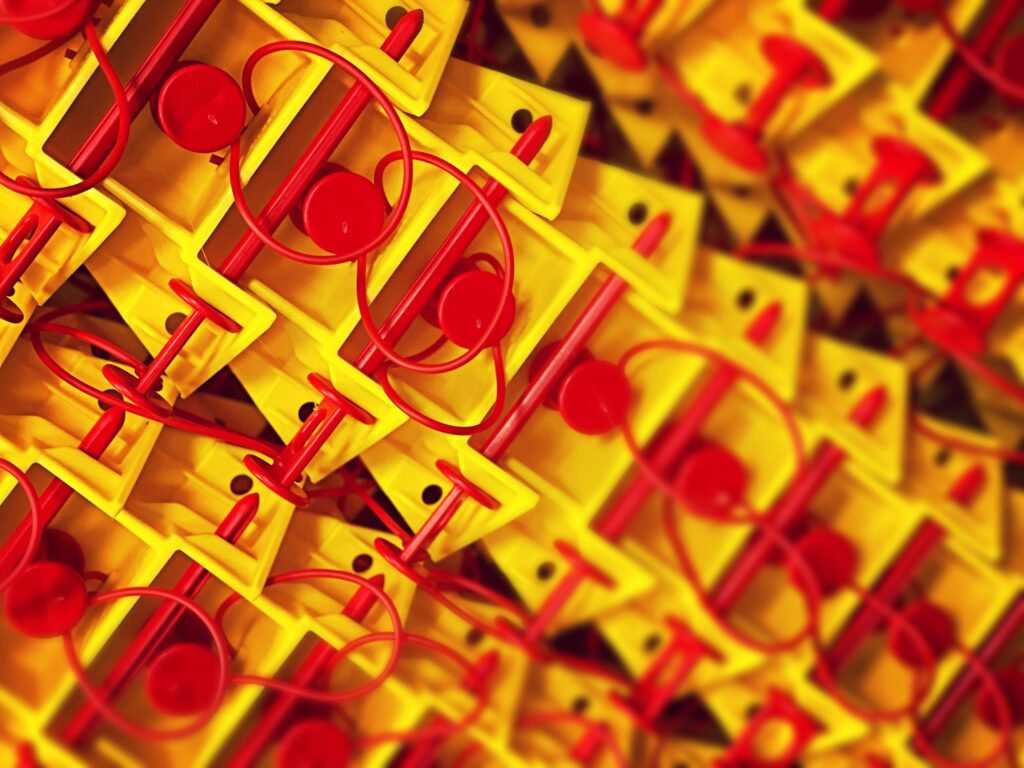

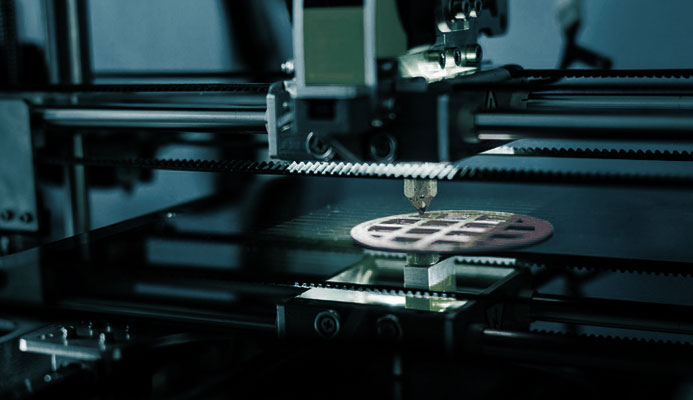

Plastic injection molding is a highly advanced manufacturing method used to produce precise, high-quality plastic components and products. This process involves the use of specialised machinery and molds to shape raw plastic into complete, market-ready items.

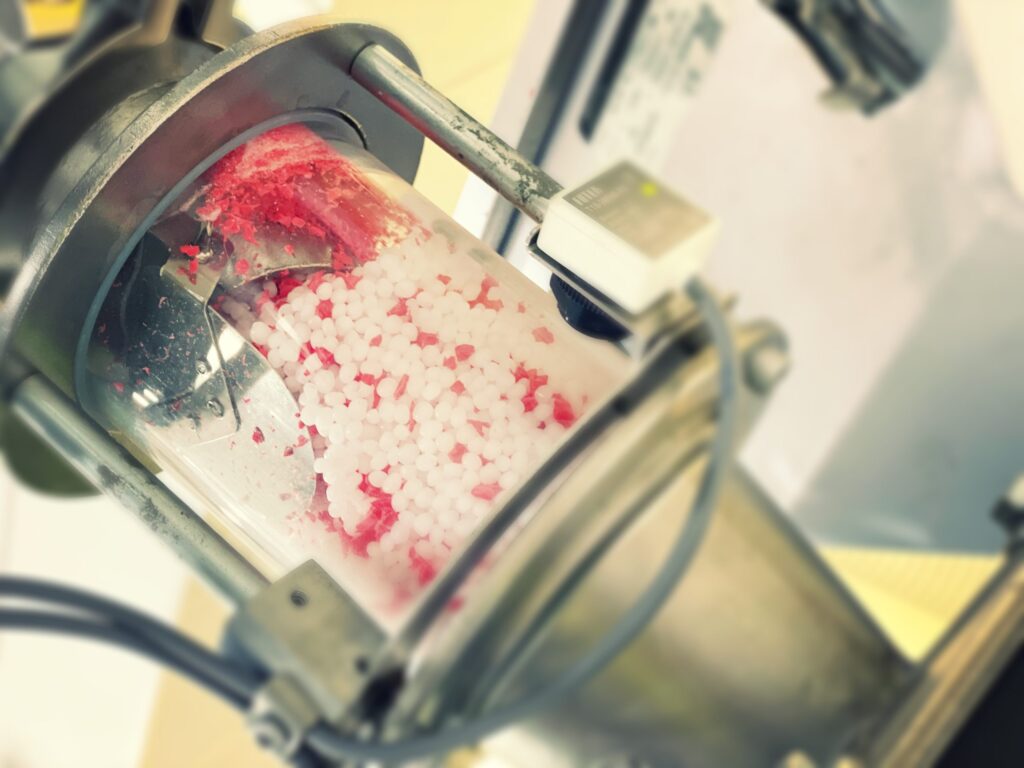

So, how does it work? First, plastic pellets are melted and injected into a mold cavity under pressure. Inside the mold, the plastic then cools and solidifies into the desired form.

Thanks to its adaptability, this technique is widely used across multiple sectors and is suitable for manufacturing products of all shapes and sizes.

Which Sectors Use Plastic Injection Molding?

Due to its flexibility and efficiency, plastic injection molding plays a vital role in the production of countless modern goods. Its ability to create both small and large components makes it indispensable in the manufacturing world.

Just some of the industries that frequently utilise plastic injection molding include automotive, aerospace, healthcare, consumer products, and electronics.

At Bosworth Plastics, we combine the latest technology with expert craftsmanship to ensure excellence across our production processes. Our strict quality control measures are embedded in every step of manufacturing, with our expert team working in unison to deliver products that meet the highest standards of accuracy and quality.

The Future Of Manufacturing?

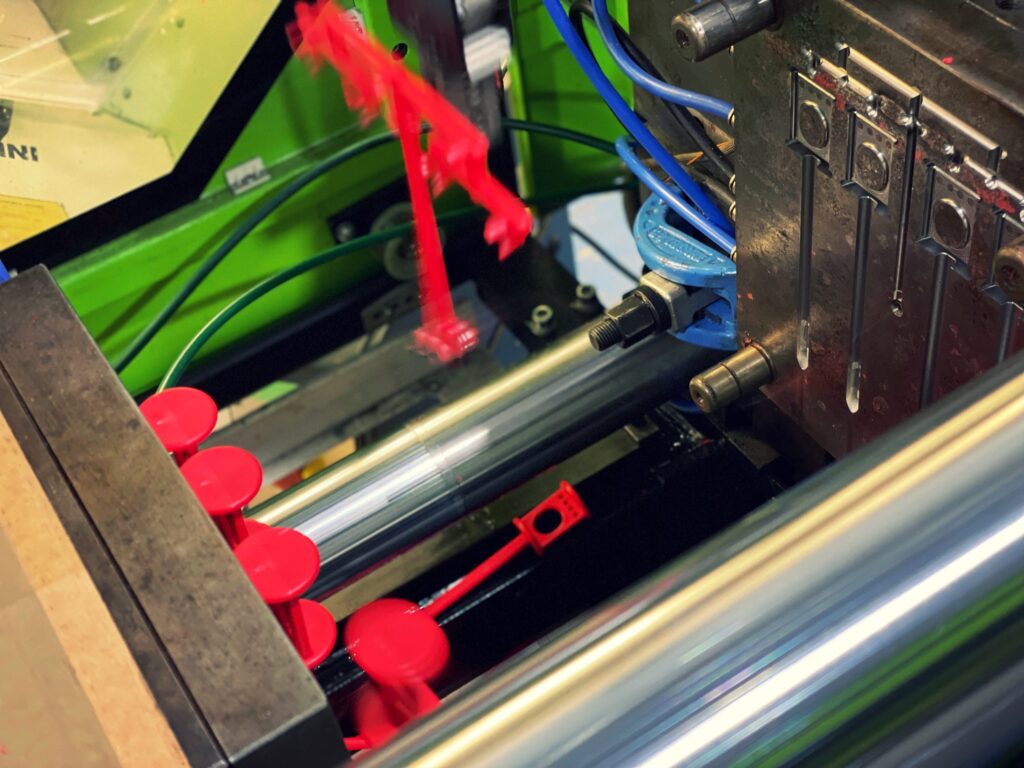

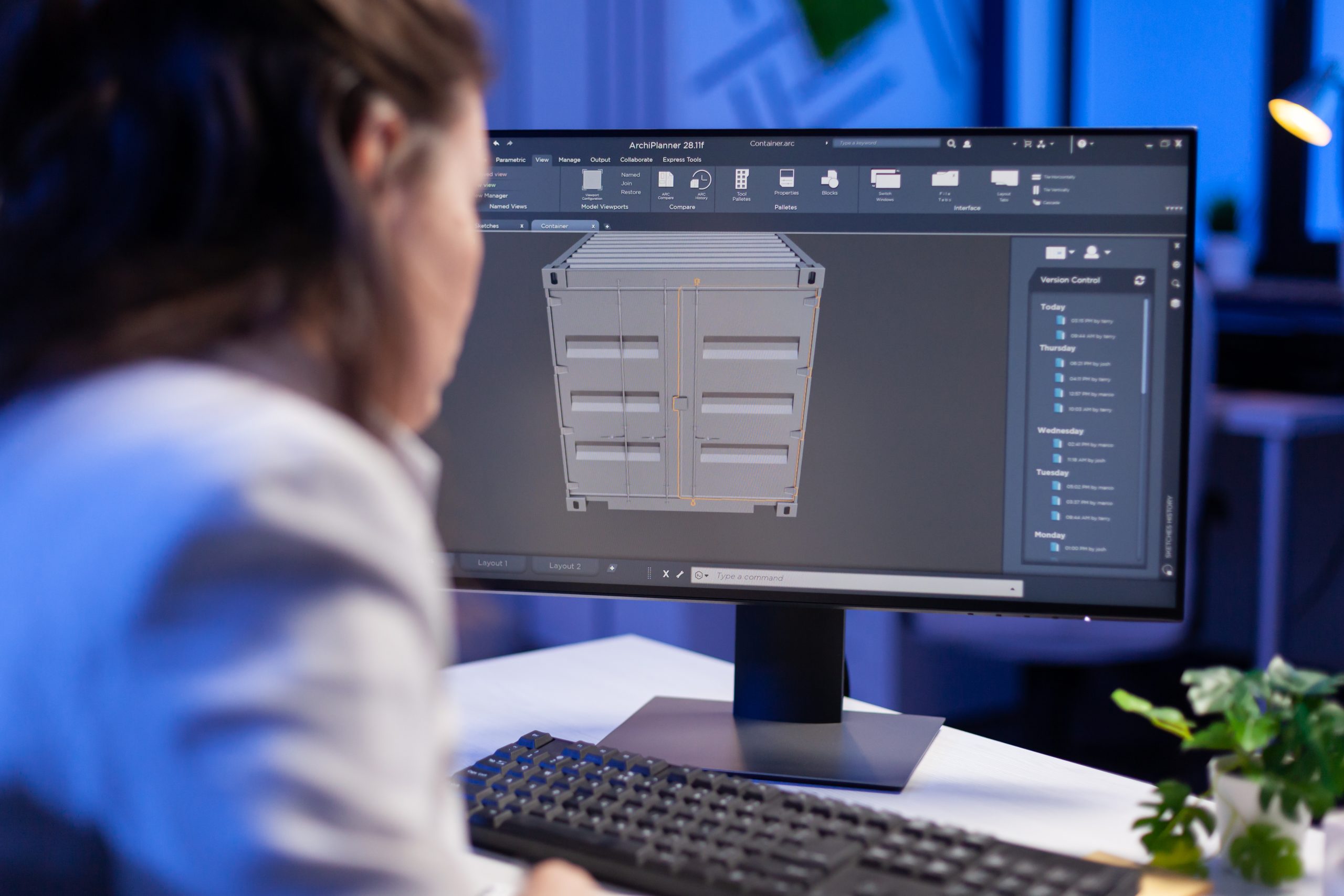

Plastic injection molding continues to evolve over time, incorporating innovative technologies such as computer-aided design (CAD), computer-aided manufacturing (CAM), automation, and robotics to enhance design and production.

In this streamlined process, CAD technology enables the creation of detailed 3D product models with outstanding precision. These designs serve as accurate blueprints for production.

CAM systems then convert these digital designs into machine instructions, helping to maintain exact standards during manufacturing. Automation and robotics have also revolutionised the molding process. These technologies boost productivity and consistency by performing tasks like material handling, mold loading, part ejection, and inspection with exceptional speed and accuracy – all while significantly reducing errors and delays.

Why Choose Bosworth Plastics To Be Your Custom Plastic Injection Molder?

Plastic Injection Molding Expertise

Innovation thrives on experience. That’s why our operations are powered by a team of skilled manufacturing experts.

Whether you need bespoke mold tooling, complex components, or large-scale production runs, the depth and breadth of our expertise guarantee consistent, high-quality results every time.

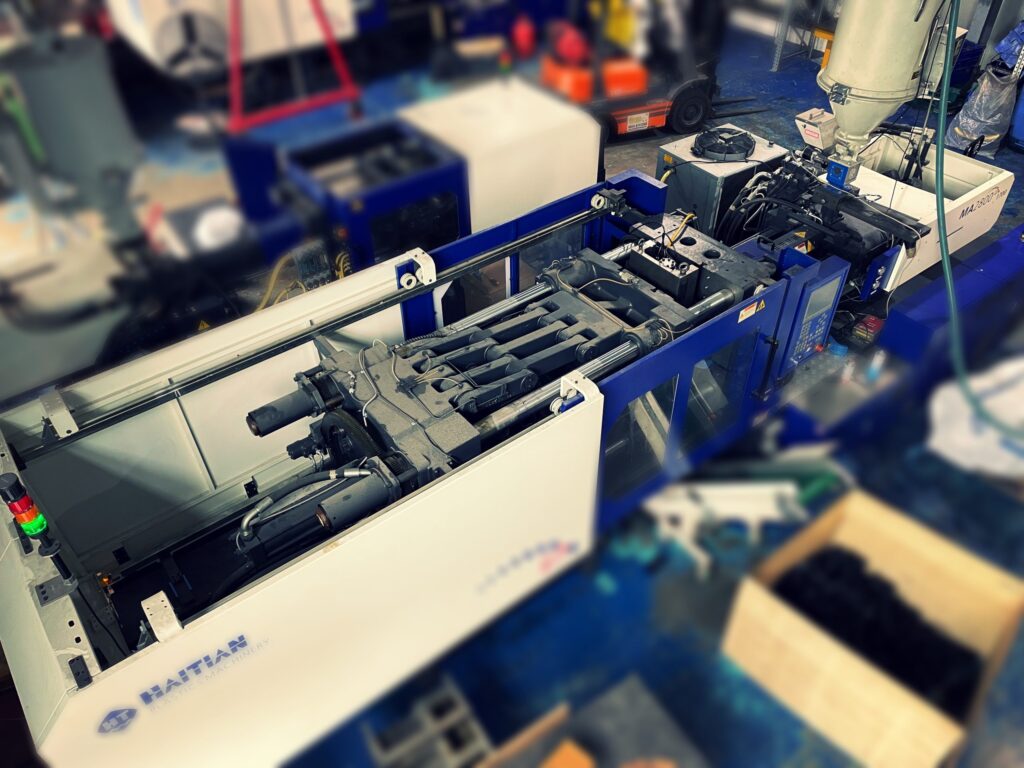

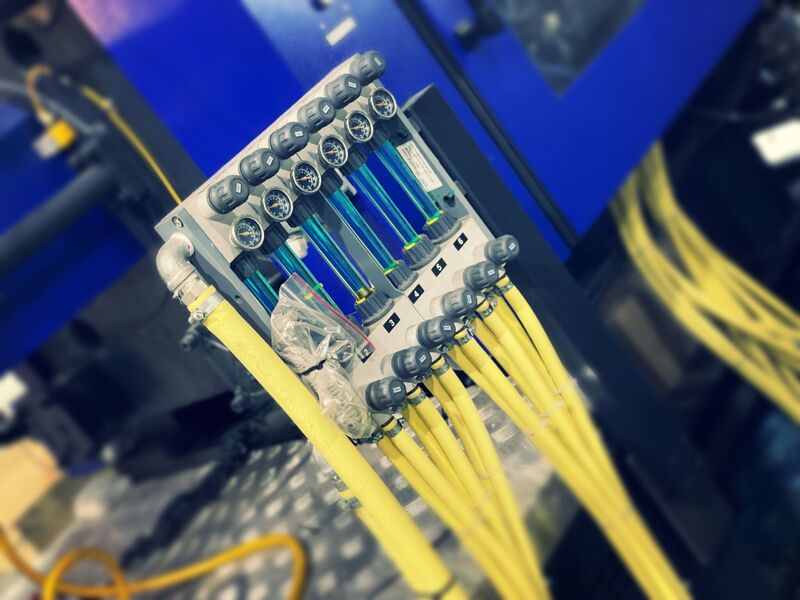

Cutting-Edge Technology

We maintain the highest industry standards through state-of-the-art machinery and technology. Our equipment can produce tooling using a wide variety of raw materials, offering both flexibility and precision in every project.

And guided by sustainability principles, we aim to minimise material waste and reduce our environmental impact throughout the manufacturing cycle.

Custom Solutions

Every project is unique. That’s why we provide tailored solutions based on your individual needs and specifications.

Our expert engineers and designers will work closely with you throughout the design and production phases, delivering mold tools that meet your vision and strict quality requirements.

Quality Assurance

Quality is central to everything we do. Our ISO-certified quality management systems ensure that every product we manufacture adheres to strict performance standards.

From material selection through to final inspection, our quality assurance processes guarantee durability, accuracy, and long-term reliability!

Competitive Pricing

We believe high-quality manufacturing shouldn’t come at a high price.

Our efficient production methods and economies of scale enable us to offer cost-effective solutions without compromising quality—helping you maximise your return on investment.

On-Time Delivery

Timely delivery is crucial to maintaining your schedule and reputation.

Our streamlined workflows and rigorous project management mean we consistently deliver projects on time and in excellent condition.

Customer-Centred Services

We put our clients first. Our approach is collaborative, transparent, and responsive.

Whether you have feedback, questions, or need support at any stage, our dedicated customer service team is here to help ensure a smooth and successful project experience.

Get In Touch!

Bosworth Plastics is your perfect partner for high-quality plastic injection mold tooling services. From one-off prototypes to large-scale manufacturing, we have the expertise, equipment, and attention to detail that ensures we deliver exceptional results for every client.

If You’re Looking For A Top-Quality Custom Plastic Injection Molder, Make Sure You Contact Us!

Plastic Injection Moulded Product Specialist