At Bosworth Plastics, we take pride in partnering with businesses across the UK and beyond to transform innovative ideas into high-quality, precision-engineered plastic components. With over 20 years of expertise in injection moulding and a commitment to UK manufacturing excellence, our dedicated team guides clients through every stage – from initial concept to final delivery and aftercare.

Whether you’re developing a new product, scaling production, or seeking reliable UK-based manufacturing, understanding the process is key to achieving consistent results, minimising costs, and accelerating time to market. In this guide, we walk you through the essential steps to successfully get your plastic parts injection moulded.

1. The Brief: Defining Your Vision and Requirements

Everything starts with a clear understanding of your needs. Share your product idea, specifications, intended application, volume requirements, material preferences, and any regulatory standards (e.g., food-grade, medical, or automotive compliance).

At Bosworth Plastics, our experts review your brief in detail, asking targeted questions to refine the scope and identify potential challenges early. This collaborative step ensures alignment and sets a strong foundation for success.

2. Research & Development (R&D): Exploring Feasibility

Our team conducts thorough R&D to assess material options, design viability, and manufacturing considerations. We evaluate factors like part geometry, wall thickness, draft angles, and shrinkage to optimise for injection moulding.

This phase often includes initial cost estimates and timelines, helping you make informed decisions before committing to tooling.

3. Concept Development: Bringing Ideas to Life

Working closely with you, we develop detailed concepts that balance functionality, aesthetics, and manufacturability. Using advanced CAD software, our designers create precise 3D models that capture your vision while incorporating best practices for high-quality moulding.

Feedback loops at this stage allow refinements, ensuring the design is production-ready and cost-effective.

4. Visualisation: Realistic Previews and Prototyping

Before investing in full tooling, we provide high-fidelity visualisations and rapid prototypes (e.g., 3D printed or low-volume moulded samples). This allows you to test form, fit, and function in real-world conditions.

Prototyping helps catch any issues early, saving time and money compared to discovering problems during production.

5. Tooling Design and Manufacture: Building Precision Moulds

Tooling is the heart of injection moulding. Our in-house experts design robust, high-precision moulds tailored to your part requirements, material choice, and production volumes.

We use advanced CNC machining and EDM processes to create durable tools that deliver consistent, repeatable results. At Bosworth Plastics, we prioritise quality tooling to minimise defects and maximise tool life.

6. Sampling and Quality Testing: Validating Performance

Once the mould is complete, we run initial samples (often called T0 or T1 trials) to fine-tune process parameters like temperature, pressure, and cycle time.

Rigorous quality testing-including dimensional checks, material property verification, and functional assessments-ensures parts meet your exact specifications and industry standards. Adjustments are made iteratively until approval.

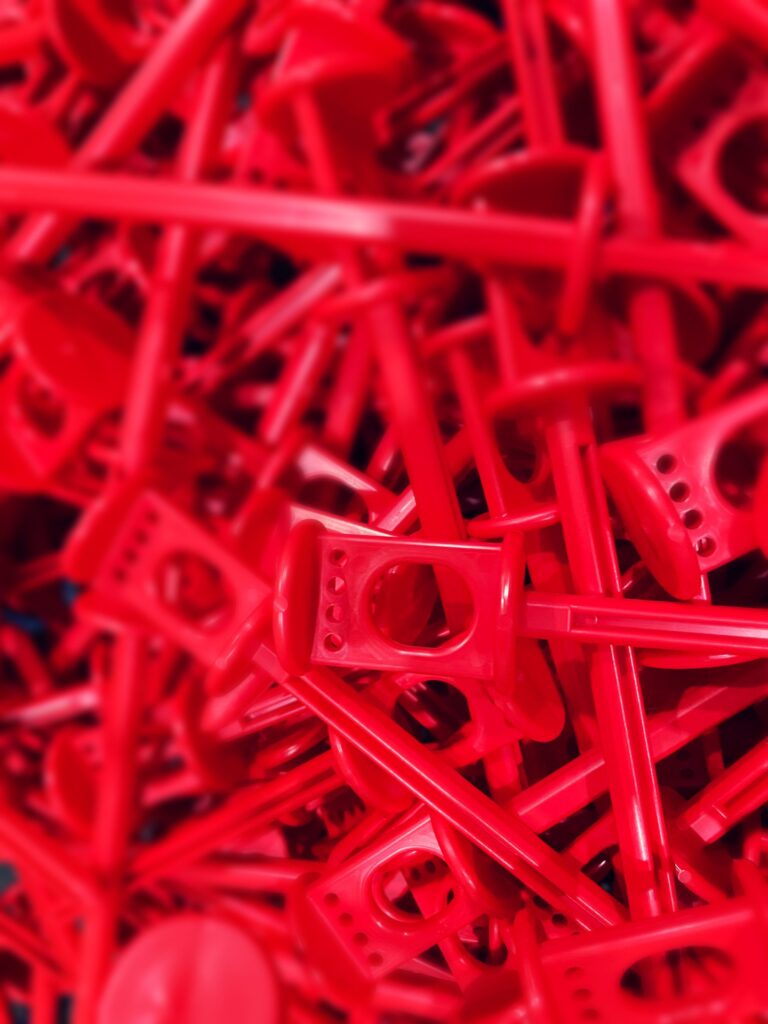

7. Full Production: Scaling with Confidence

With validated samples and optimised settings, we move into full production runs. Our modern injection moulding machines, combined with strict process controls and ISO 9001:2015 accreditation, guarantee high-quality output, even for complex geometries or tight tolerances.

We handle everything from low-volume bespoke runs to high-volume manufacturing, maintaining consistency across batches.

8. Delivery: On-Time and Ready for Use

Parts are carefully inspected, packaged, and delivered according to your schedule. We offer flexible logistics options to support just-in-time requirements and keep your supply chain efficient.

9. Aftercare: Ongoing Support and Partnership

Our relationship doesn’t end at delivery. We provide ongoing support, including maintenance advice, spare parts, design tweaks for future iterations, or scaling production as your needs grow.

At Bosworth Plastics, we’re committed to being a long-term partner, helping you adapt and innovate over time.

Why Choose Bosworth Plastics for Your UK Injection Moulding Project?

By following this structured approach, you gain peace of mind knowing your project is in expert hands. Our UK-based facility, passion for craftsmanship, and focus on innovation ensure superior quality, reduced lead times, and support for British manufacturing.

Ready to turn your concept into high-quality plastic parts? Contact the team at Bosworth Plastics today to discuss your project. We’re here to guide you every step of the way.