Injection Molding Services

Searching For Top-Quality Injection Molding Services?

Look No Further Than Bosworth Plastics!

At Bosworth Plastics, our injection molding services are highly trusted by discerning manufacturing companies across the UK and internationally.

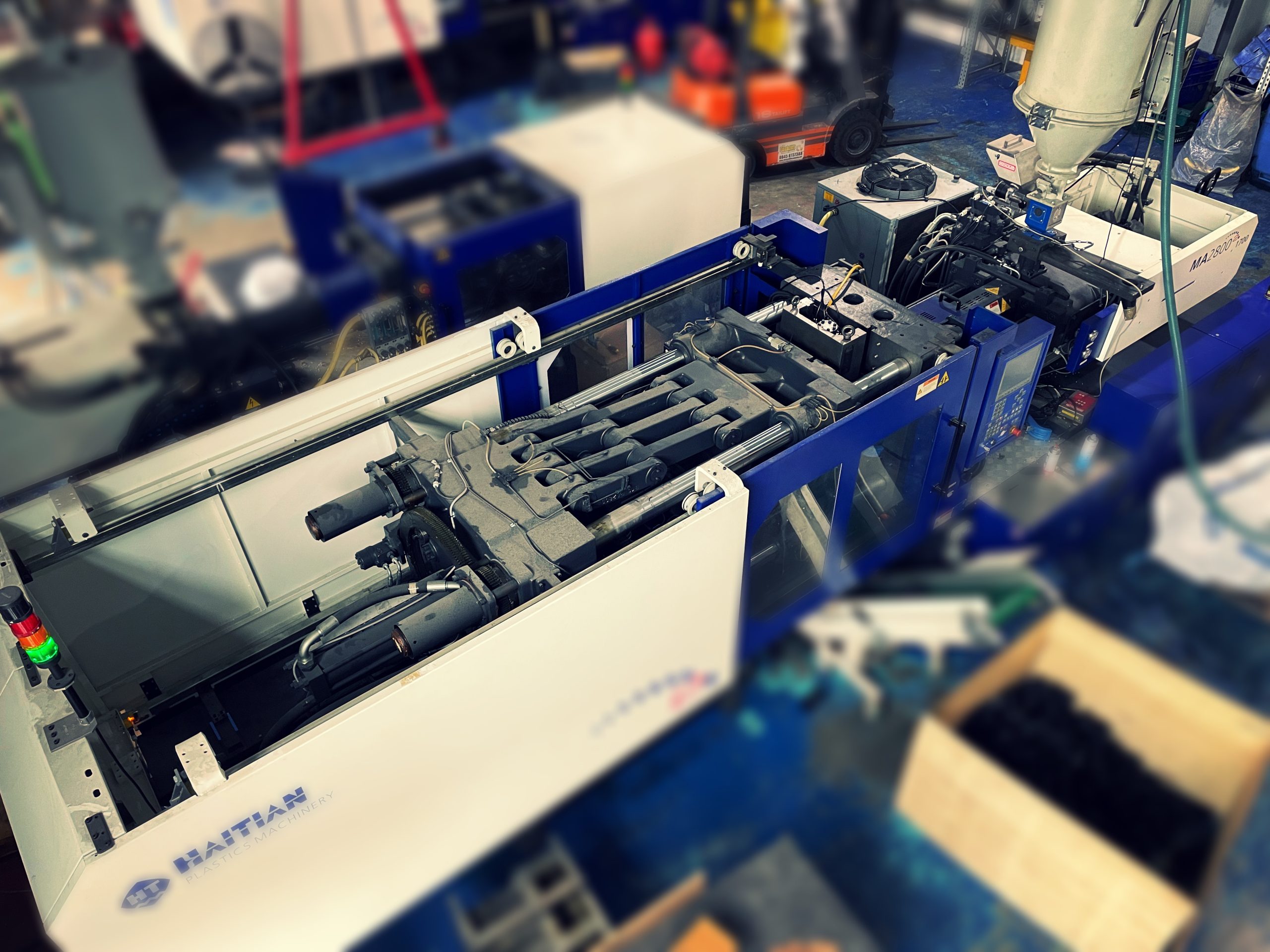

We continually refine and enhance our processes by integrating the latest developments in CAD, CAM, and automation technologies, ensuring we remain at the forefront of the industry. This allows us to deliver fast turnaround times, cost-effective solutions, and consistently high-quality tooling for our clients.

Innovation sits at the heart of everything we do. Through ongoing research and development, we actively explore new technologies and collaborate closely with industry specialists to encourage continuous improvement and technical advancement across our operations. This dedication enables us to provide an exceptional level of service and deliver outstanding results that don’t just meet expectations, but surpass them.

What Is Plastic Injection Molding?

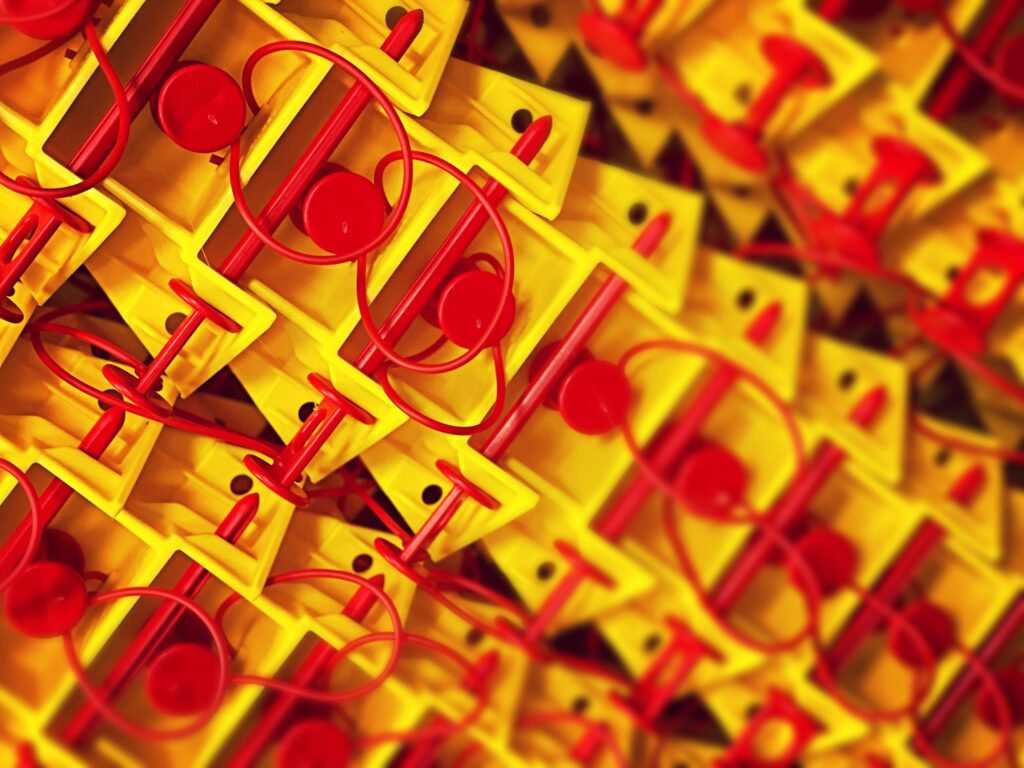

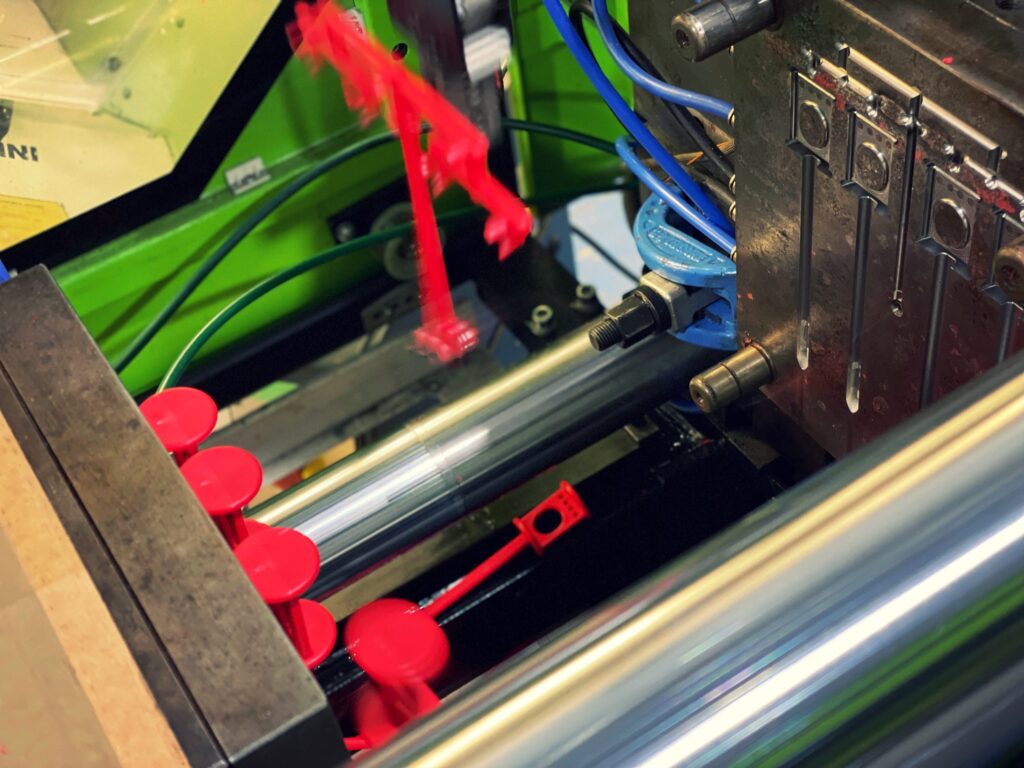

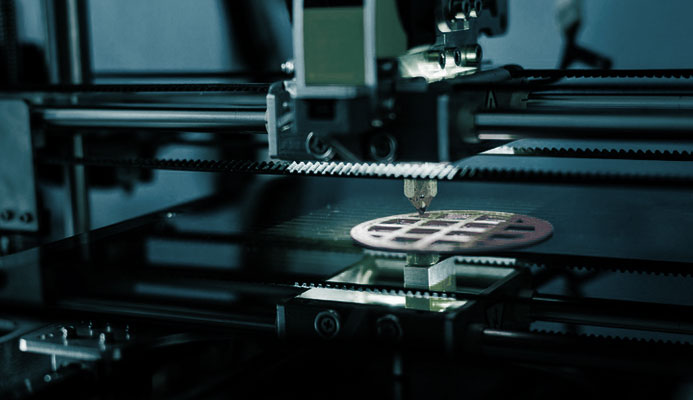

Plastic injection molding is a highly advanced manufacturing process used to produce precision-engineered plastic components and products. Using specialised machinery and custom-built molds, raw plastic material is transformed into fully finished, ready-to-use products with exceptional accuracy.

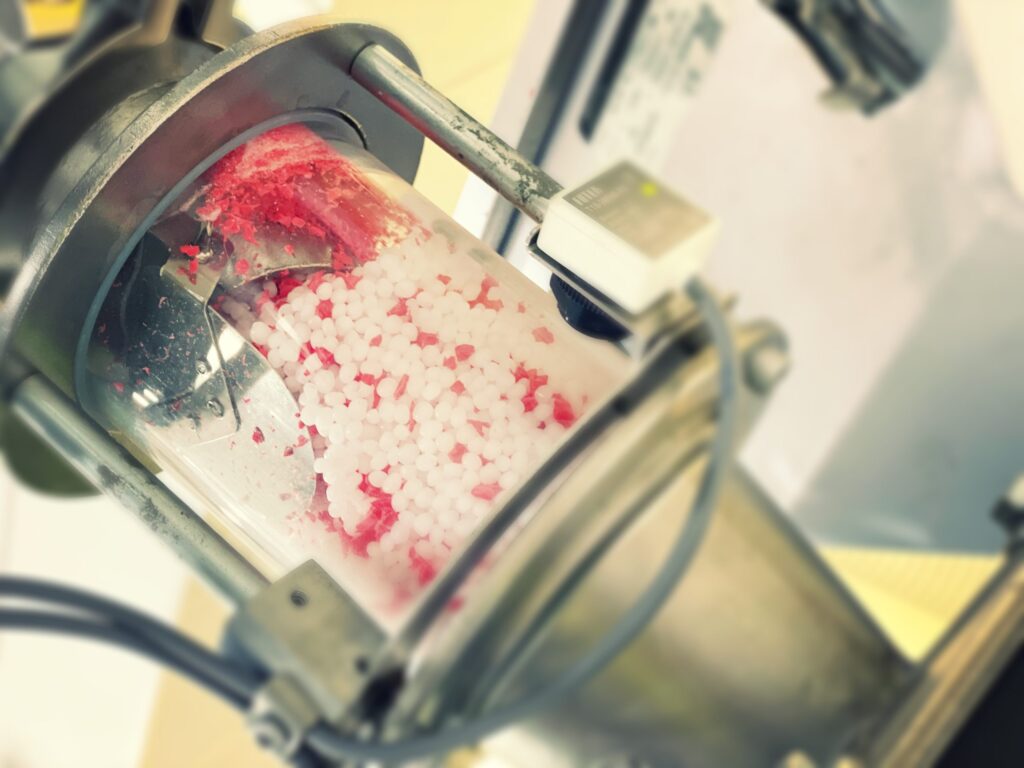

The process begins by heating plastic pellets until they melt, before injecting the molten material into a pressurised mold cavity. As the plastic cools, it solidifies into the desired shape.

Due to its versatility and efficiency, plastic injection molding is widely used across multiple industries and is suitable for both small, intricate parts and larger components.

Which Sectors Use Plastic Injection Molding?

Thanks to its adaptability, plastic injection molding plays a vital role in the production of countless products found in today’s marketplace.

The process supports both low and high-volume manufacturing, making it indispensable across a wide range of sectors. Industries that routinely rely on plastic injection molding include automotive, aerospace, healthcare, consumer goods, and electronics.

At Bosworth Plastics, we combine advanced manufacturing technologies with skilled craftsmanship to deliver precision-engineered tooling. Quality control is embedded at every stage of our operations, with our experienced team working collaboratively to ensure consistent accuracy and reliability in every finished product.

The Future Of Manufacturing?

Plastic injection molding continues to evolve through the adoption of cutting-edge technologies such as computer-aided design (CAD), computer-aided manufacturing (CAM), automation, and robotics. These advancements enhance both product development and manufacturing efficiency.

CAD systems are used to create highly detailed 3D designs with exceptional precision, providing manufacturers with a clear and accurate blueprint of the final product. CAM systems then convert these designs into machine-readable instructions, streamlining production while maintaining consistency and accuracy.

Automation and robotics have significantly increased production speed and efficiency. Automated systems can manage tasks requiring extreme precision and repeatability, including material handling, mold loading, component ejection, and quality inspection—boosting productivity while reducing the risk of errors.

Why Choose Bosworth Plastics For Injection Molding Services?

We’re proud to deliver industry-leading tooling solutions for plastic injection molding to the UK manufacturing sector. We are dedicated to upholding the highest standards of quality, precision, and technical expertise for our valued clients.

Our modern facilities feature advanced CAD, CAM, and automated technologies, operated by a highly skilled team of plastic injection molding specialists. Choosing Bosworth Plastics means investing in the long-term success and performance of your product designs.

Our services provide a wide range of benefits, including:

Plastic Injection Molding Expertise

At Bosworth Plastics, we recognise that true innovation is driven by experience and knowledge. Our operations are guided by a team of seasoned industry professionals with extensive expertise in plastic injection mold tooling.

From bespoke tooling solutions and complex components to high-volume production runs, we have the capability to deliver consistently high-quality results.

With experience spanning industries such as automotive, aerospace, medical devices, and consumer electronics, we’re fully equipped to meet your tooling requirements to the highest standard.

Cutting Edge Technology

We adhere to the most demanding industry standards by investing in state-of-the-art machinery and advanced manufacturing technologies.

Our equipment supports tooling production using a broad range of materials, from standard plastics to high-performance polymers, ensuring flexibility and precision across all projects.

Sustainability is a key focus of our operations, and we actively work to reduce waste and minimise environmental impact throughout the manufacturing process.

Custom Solutions

Every project at Bosworth Plastics is approached with flexibility and attention to detail. We provide tailored tooling solutions that align with your specific requirements and technical specifications.

Our engineers and designers work closely with you throughout the process, adopting a collaborative, customer-focused approach to ensure your mold tooling meets both functional and quality expectations.

From initial prototyping to full-scale production, we deliver end-to-end support and dedicated customer care.

Quality Assurance

Quality assurance is integral to our manufacturing operations. We operate ISO-certified quality management systems to ensure every tool we produce meets strict quality benchmarks.

Our commitment to excellence is demonstrated through thorough quality inspections at every stage of production, from material selection through to final approval. This ensures long-lasting, reliable tooling you can depend on.

Competitive Pricing

We understand the importance of balancing quality with cost efficiency. That’s why Bosworth Plastics offers premium tooling solutions at competitive prices, helping our clients remain commercially competitive.

By leveraging efficient production methods and economies of scale, we provide cost-effective solutions that maximise return on investment without compromising on quality.

On Time, Every Time

Meeting deadlines is critical in today’s manufacturing environment. Our streamlined workflows and robust project management processes ensure every order is delivered on schedule.

When you choose Bosworth Plastics, you can rely on a dependable service that delivers your tooling on time and in excellent condition.

Customer-Centred Services

Our clients are at the centre of everything we do. We work closely with you throughout your project and welcome open communication, feedback, and collaboration at every stage.

Our dedicated customer support team is always available to guide you through the process and ensure you get the maximum value from our services.

Get In Touch!

Bosworth Plastics is your reliable partner for plastic injection mold tooling solutions. Whether you require small prototypes or large-scale production, we have the expertise, technology, and capacity to support your manufacturing needs.

Get in touch today to arrange a consultation with our expert team, receive your free quote, and take the first step towards bringing your project to life.

If You’re Looking For Top-Quality Injection Molding Services, Make Sure You Contact Us!