Injection Moulding Toolmakers

Looking For Top-Quality Injection Moulding Toolmakers?

Look No Further Than Bosworth Plastics!

Bosworth Plastics are proud to be at the cutting-edge of the UK’s manufacturing industry, setting the benchmark for the precision, quality, and expertise of injection moulding toolmakers.

We serve a wide range of clients across many sectors, backed by state-of-the-art facilities and a highly experienced team. Our dedication to excellence means we’re perfectly suited to turning your ideas into reality, no matter how complex!

Why Choose Us As Your Injection Moulding Toolmakers?

Expertise You Can Trust

At Bosworth Plastics, we appreciate that every injection moulding project is unique. That’s why we take great pride in our team’s extensive knowledge and hands-on experience.

Whether you require bespoke mould tools, intricate components, or large-volume production runs, we have the skills to deliver.

Our successful collaborations span industries such as automotive, aerospace, medical devices, and consumer electronics, consistently producing outstanding results.

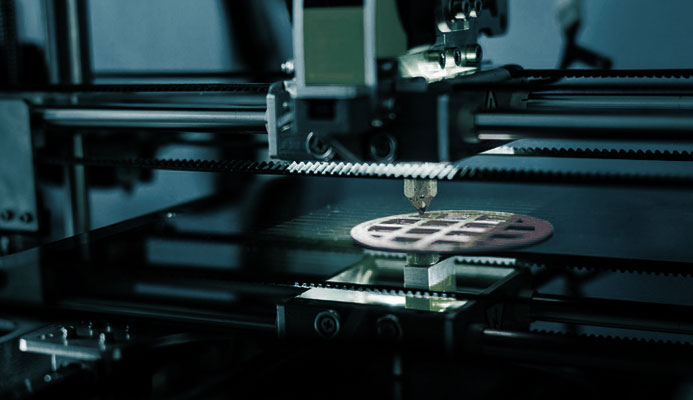

Advanced Technology At Your Service

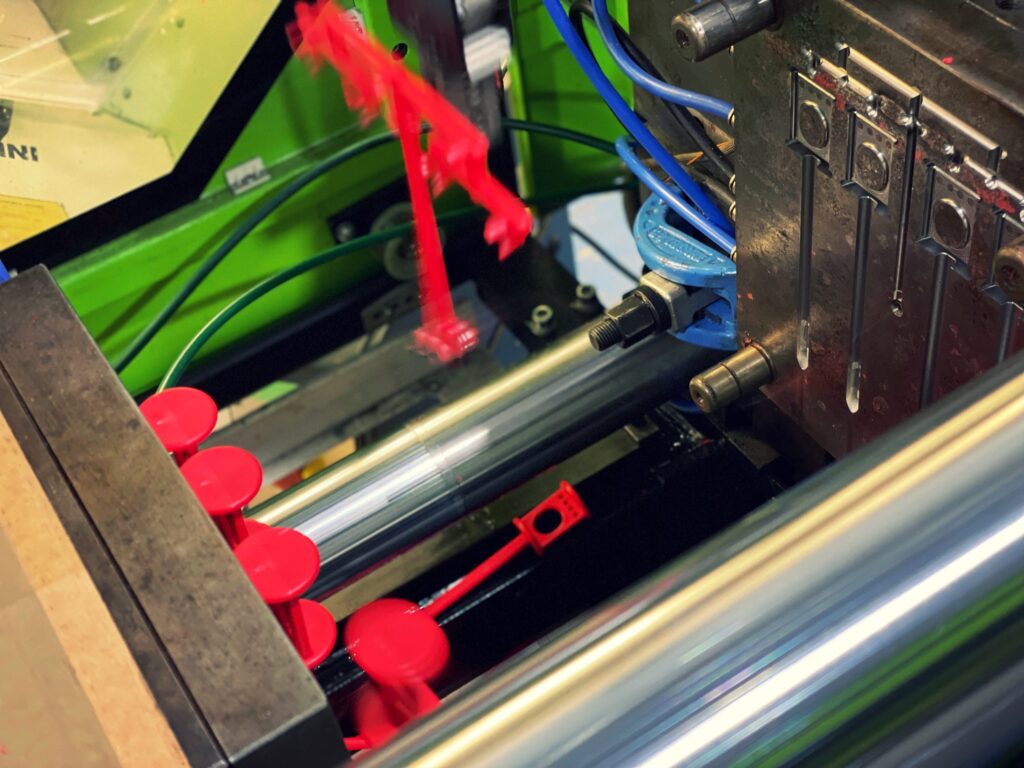

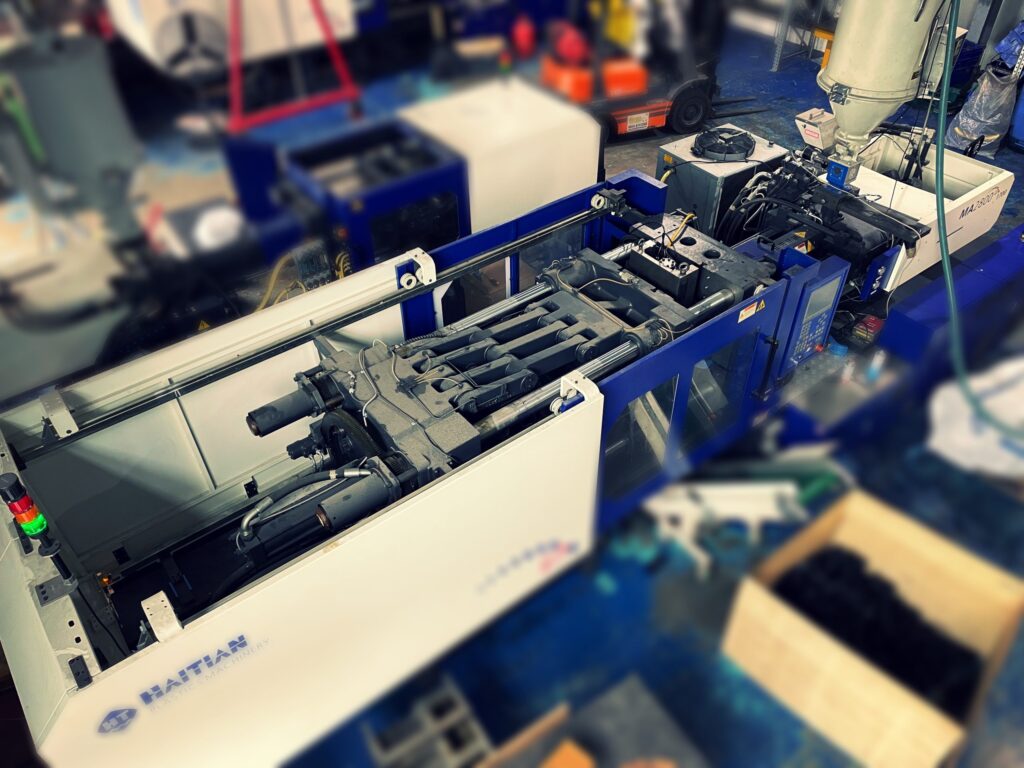

To meet the highest industry standards, we invest heavily in the latest technology and machinery.

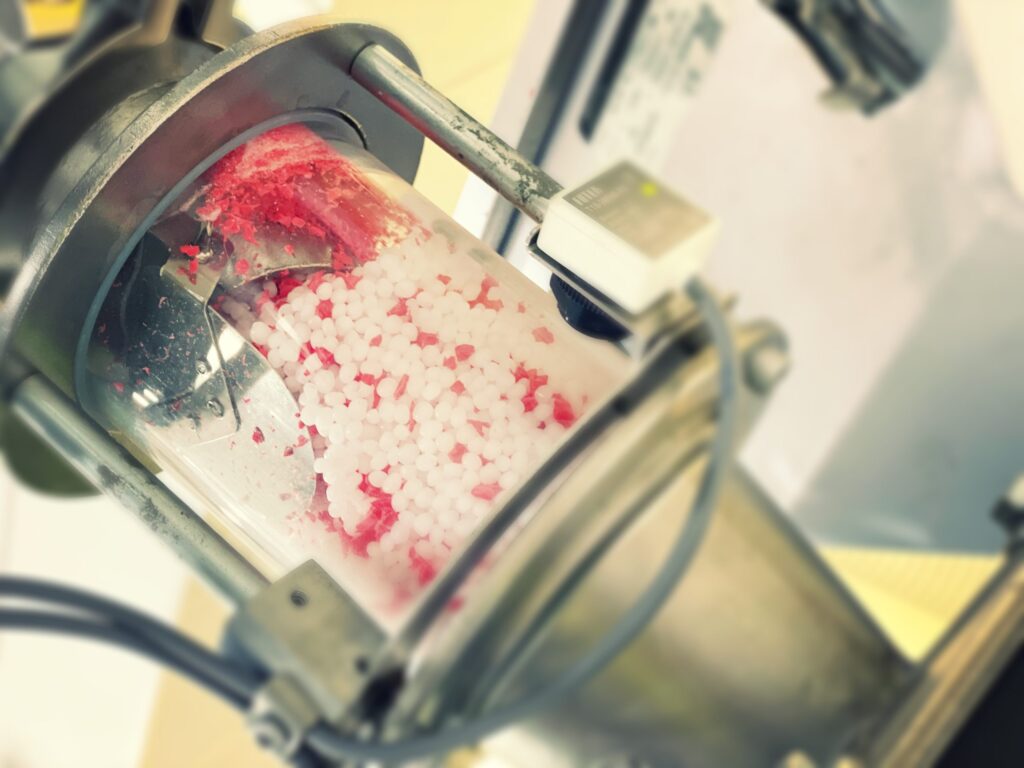

Our modern equipment can handle an extensive range of materials, from everyday commodity plastics to specialist high-performance polymers. This means we offer both precision and flexibility for every project.

Plus, we’re committed to sustainability – working hard to reduce waste and minimise environmental impact throughout our processes.

Tailored Solutions Just For You

We understand that your project has its own specific needs. That’s why we offer bespoke tooling solutions, designed and engineered in close collaboration with you.

From initial prototype stages to full production, we provide comprehensive support every step of the way to ensure your vision is realised with the highest quality.

Rigorous Quality Assurance

Quality is at the heart of everything we do. Our processes are certified to ISO standards, and we maintain strict quality controls throughout every stage of production – from material selection right through to final inspection.

This dedication guarantees products that not only meet but often exceed your expectations, built to last and perform reliably.

Competitive Pricing Without Compromise

We appreciate the importance of cost-effectiveness in today’s market.

Thanks to streamlined production methods and economies of scale, we offer highly competitive pricing while maintaining exceptional quality – helping you get the best return on your investment.

Customer-Focused Service

Our clients’ satisfaction is our top priority, which is why we’re proud to offer a transparent and collaborative approach, always listening carefully to your needs and feedback.

Plus, our dedicated customer support team is on hand throughout your project to ensure a smooth and trouble-free experience.

How Injection Moulding Toolmakers Shape The Modern World

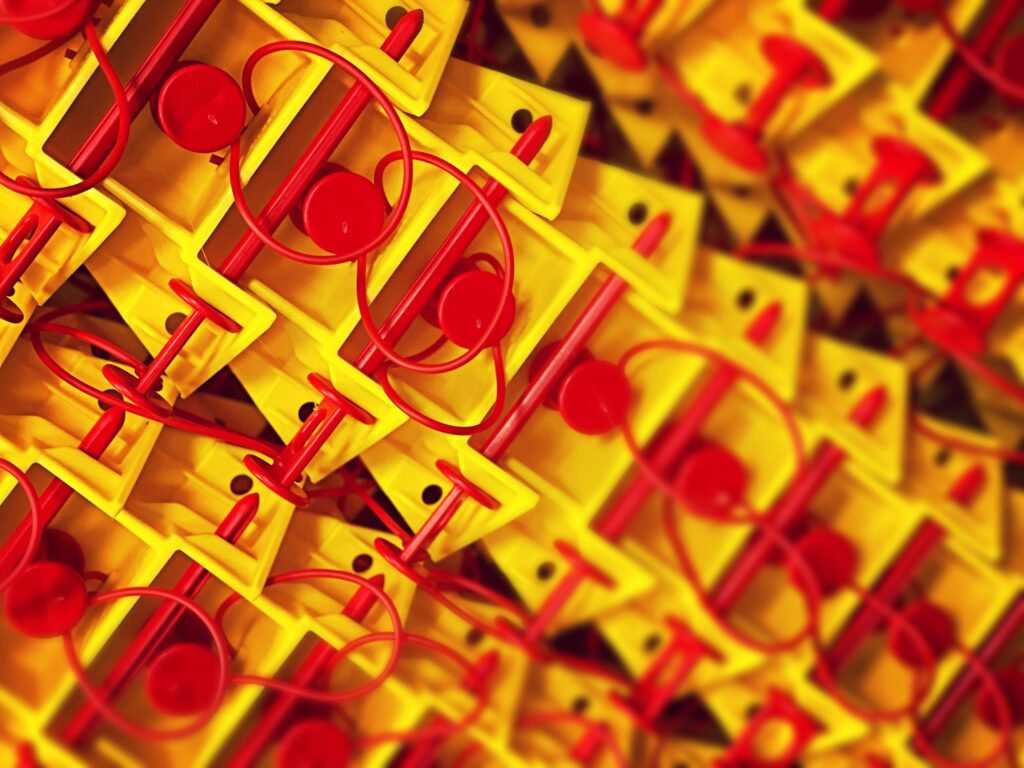

Injection moulding is a sophisticated manufacturing method that allows the production of detailed, high-quality plastic parts and products. It involves melting plastic pellets and injecting them under high pressure into moulds where they cool and solidify into the desired shape. This versatile process caters to a huge variety of product sizes and complexities, making it essential across many industries.

From automotive and aerospace to healthcare, consumer goods, and electronics, injection moulding plays a vital role. It allows the production of everything from complex medical devices to durable automotive components.

At Bosworth Plastics, we’ve perfected this craft by combining the latest technology with skilled craftsmanship. Our engineers, technicians, and craftsmen work closely together to ensure every product we produce meets the highest standards of precision and quality.

How Modern Technology Drives Our Success

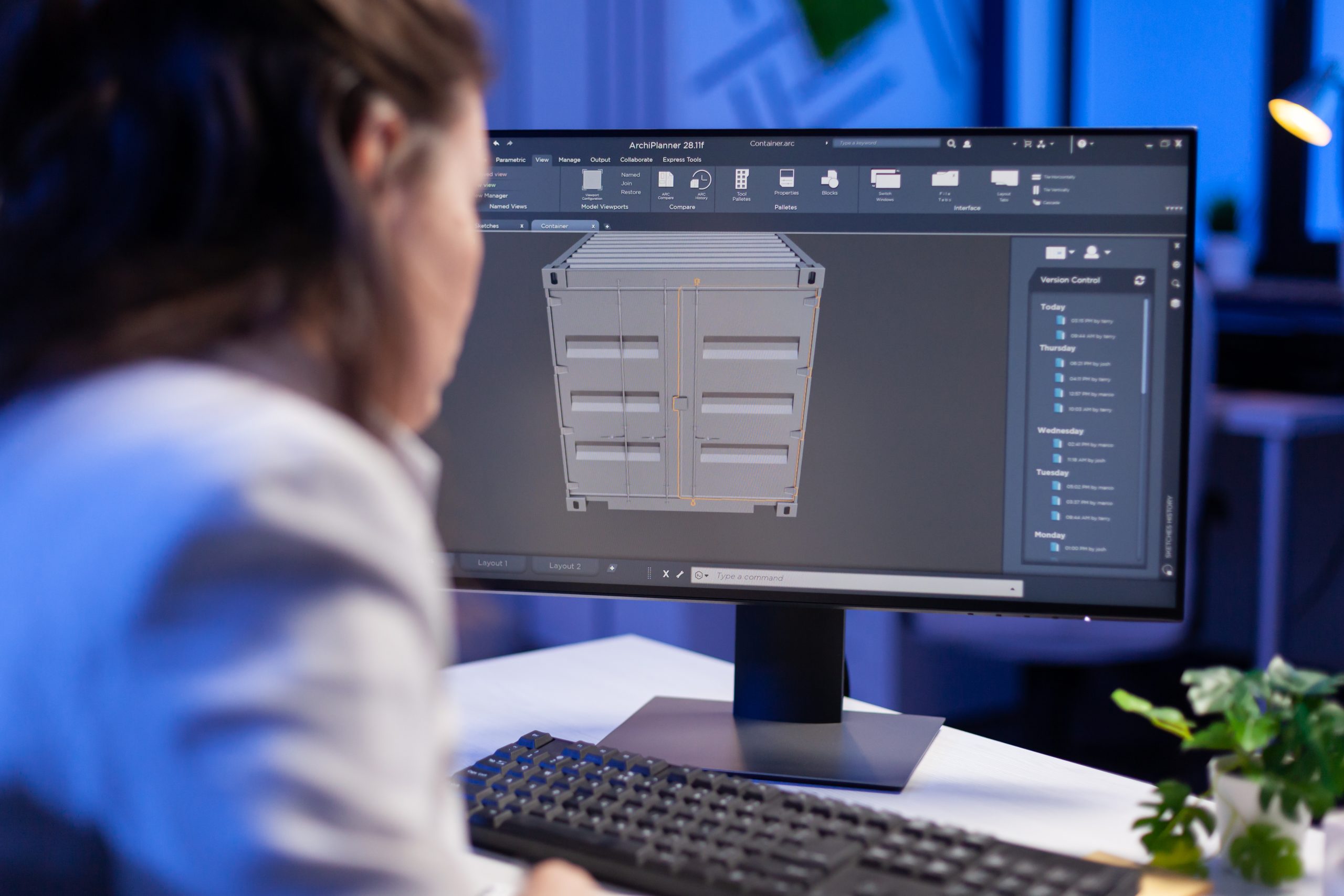

The digital age has transformed injection moulding. Tools such as computer-aided design (CAD) and computer-aided manufacturing (CAM) have revolutionised the way we design and produce mould tools. CAD allows us to create precise 3D models that serve as clear blueprints, while CAM converts these designs into instructions for our machines, streamlining production, and enhancing accuracy.

Automation and robotics have further boosted efficiency, handling tasks like material feeding, mould loading, part ejection, and quality inspections with speed and precision, thereby reducing errors and improving productivity.

At Bosworth Plastics, we’re constantly updating our equipment and processes to stay ahead of the curve. This means faster turnaround times, improved cost-efficiency, and consistently excellent products for our clients. Our investment in research and development keeps us at the cutting edge, ensuring we deliver products that meet – and exceed – the latest industry standards.

Get In Touch!

If you need reliable, industry-leading injection moulding toolmakers, Bosworth Plastics is the partner you can count on. Whether it’s a small prototype or a large-scale production run, we have the expertise and resources to exceed your expectations.

Contact us today to discuss your project, request a quote, or arrange a consultation with our expert team.

If You’re Looking For Top-Quality Injection Moulding Toolmakers, Make Sure You Contact Us!

Plastic Injection Moulded Product Specialist