Plastic Injection Mould Toolmakers

Searching For Top-Quality Injection Mould Toolmakers?

Look No Further Than Bosworth Plastics!

At Bosworth Plastics, we are a leading light of the UK’s manufacturing industry, delivering precision, quality, and expertise for discerning clients across a wide range of sectors.

With our state-of-the-art facilities, experienced team, and commitment to excellence, we are ready, willing, and more than capable of bringing your plastic manufacturing projects to life!

Why Choose Us To Be Your Plastic Injection Mould Toolmakers?

Unparalleled Expertise

At Bosworth Plastics, we understand that each plastic injection moulding project is unique. That’s why we take pride in having a team of experts who bring a wealth of knowledge and experience to the table.

Whether you require custom-designed mould tools, intricate components, or high-volume production, we have the expertise to handle it all.

We’ve worked with a diverse range of industries, from automotive and aerospace to medical devices and consumer electronics, and have consistently delivered exceptional results.

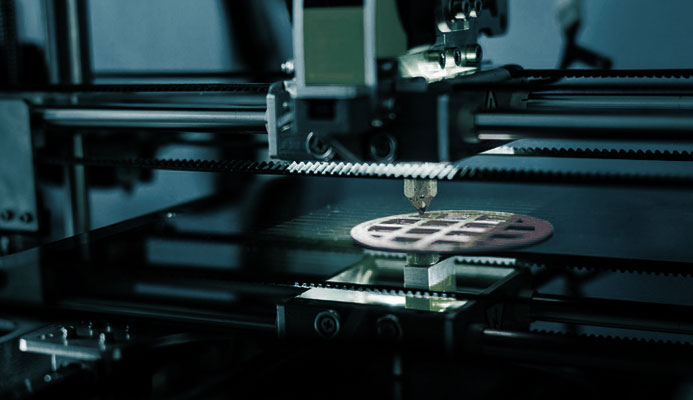

Cutting-Edge Technology

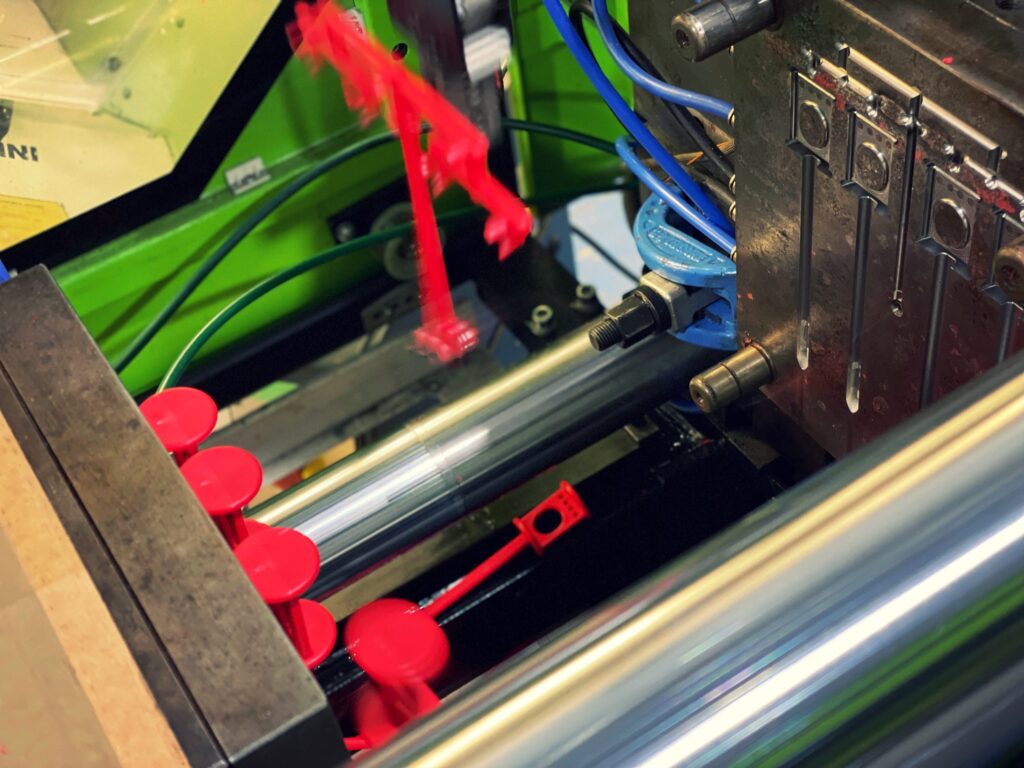

To ensure that we meet the highest industry standards, we invest in cutting-edge technology and equipment.

Our modern machines are capable of handling a wide variety of materials, from commodity plastics to high-performance polymers.

This allows us to provide you with versatility and precision in every project. Moreover, our commitment to sustainability means that we strive to minimise waste and environmental impact in our processes.

Custom Solutions

We understand that your project may have unique requirements. That’s why we offer custom solutions tailored to your specific needs.

Our team of engineers and designers will work closely with you to develop the perfect mould tool, ensuring that your final product is of the highest quality. From prototyping to production, we offer end-to-end support to bring your vision to life!

Quality Assurance

Quality is at the heart of everything we do at Bosworth Plastics. Our ISO-certified quality management systems ensure that every tool we produce meets or exceeds your expectations.

We employ rigorous quality control processes at every stage of production, from material selection to final inspection.

Our dedication to quality means you can trust us to consistently deliver products that are built to last.

Competitive Pricing

We understand the importance of cost-effectiveness in today’s competitive market. That’s why we offer competitive pricing without compromising on quality.

Our efficient production processes and economies of scale allow us to provide you with cost-effective solutions, helping you maximize your ROI.

On-Time Delivery

We understand that time is of the essence in your projects.

Our streamlined production processes – along with our commitment to punctuality – ensure that your orders are delivered on time, every time.

This means you can rely on us to meet your deadlines, helping you stay on schedule and maintain your project’s momentum.

A Customer-Centric Approach

At Bosworth Plastics, we value our customers above all else. We pride ourselves on our open and collaborative approach, always ready to listen to your feedback and address any concerns.

Our dedicated customer support team is here to assist you at every step of the way, ensuring a smooth and hassle-free experience.

How Injection Mould Toolmakers Make The Modern World Possible

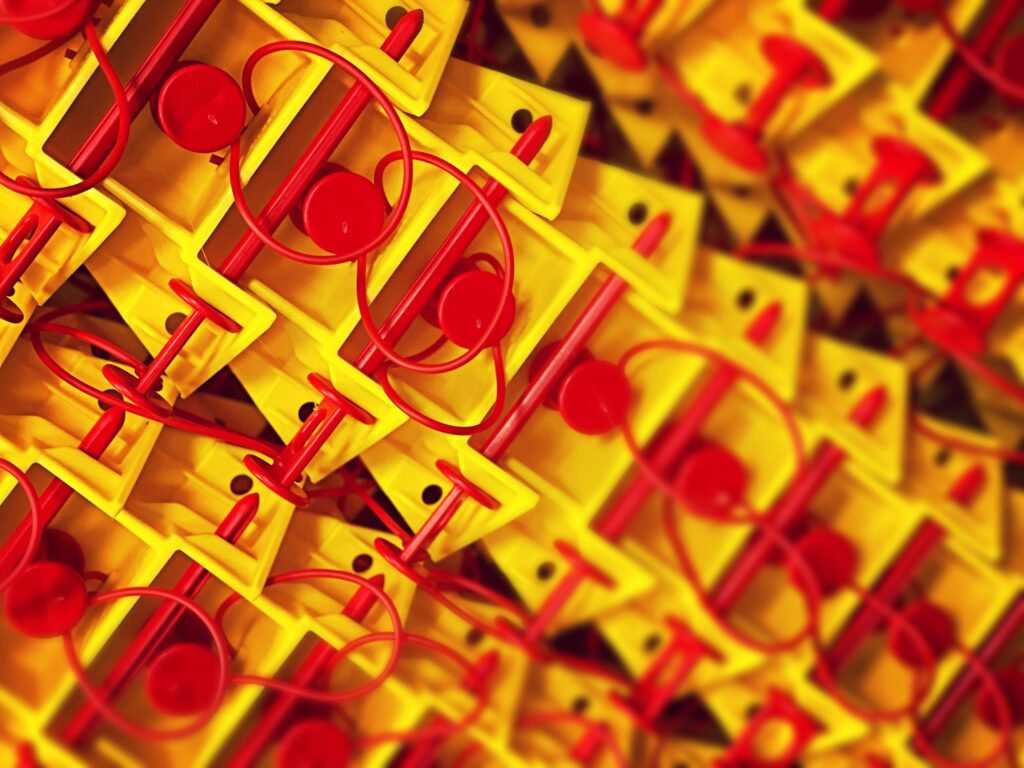

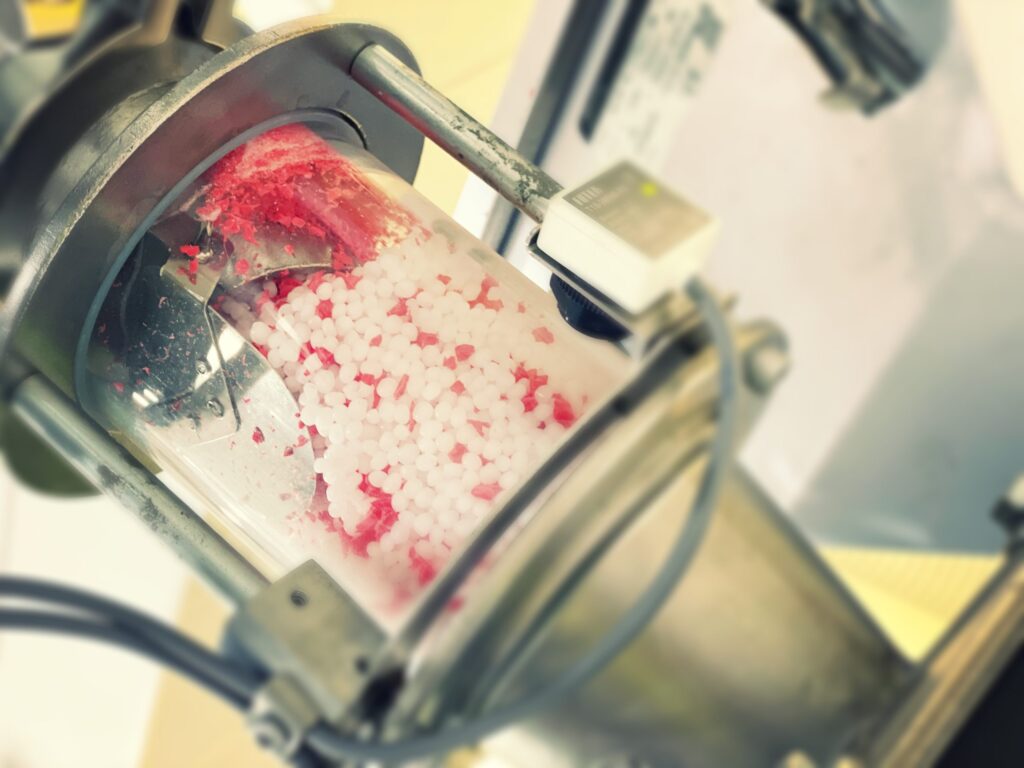

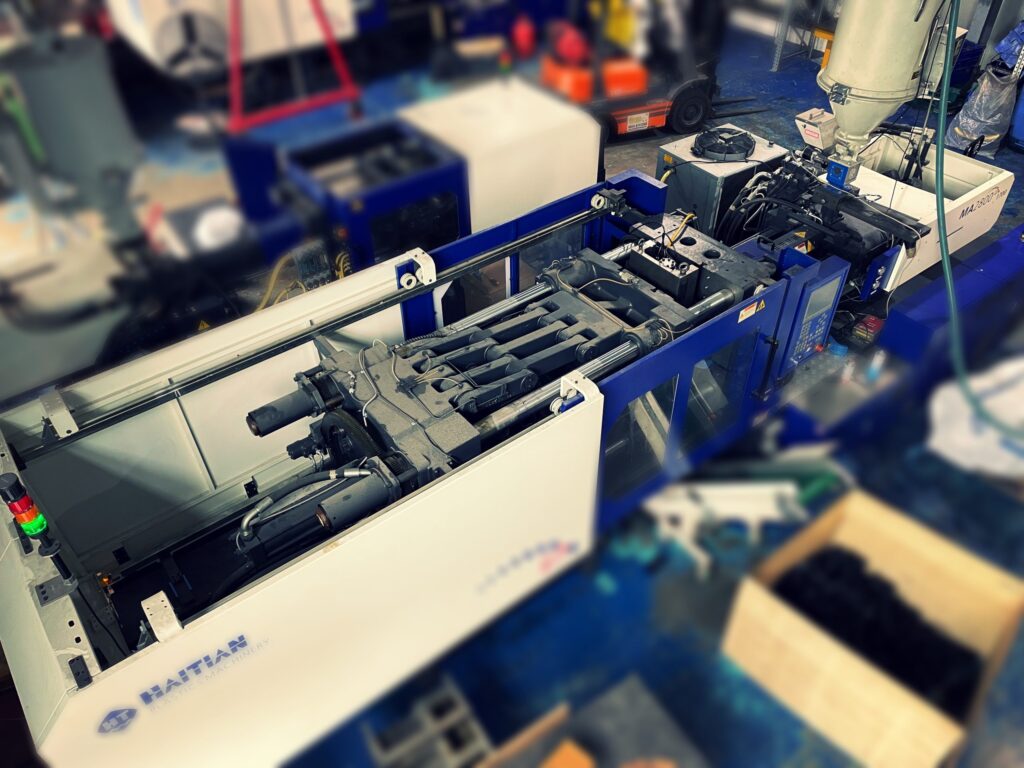

Plastic injection moulding is a complex manufacturing technique that allows for the creation of intricate, high-quality plastic parts and products. It’s a process that involves the transformation of raw plastic material – usually in the form of pellets – into finished products through the aid of specialised machinery and moulds.

The process begins with the melting of the plastic pellets, which are then injected into a mould cavity under high pressure. The material cools and solidifies within the mould, assuming the desired shape. This versatile method caters to a wide range of product sizes, complexities, and applications, making it a preferred choice across numerous industries.

Today, plastic injection moulding is a pillar of modern manufacturing, influencing various industries and shaping the world we live in. It serves as a vital cog in the machinery of various sectors, including automotive, aerospace, healthcare, consumer goods, and electronics. Its versatility allows for the production of diverse components, from intricate medical devices to robust automotive parts.

Bosworth Plastics has mastered this art, amalgamating technology and craftsmanship to deliver exceptional products. Our team of skilled engineers, technicians, and craftsmen work in synchrony to ensure that every item produced adheres to the highest standards of quality and precision!

How Plastic Injection Mould Toolmakers Use Modern Technology To Ensure Success

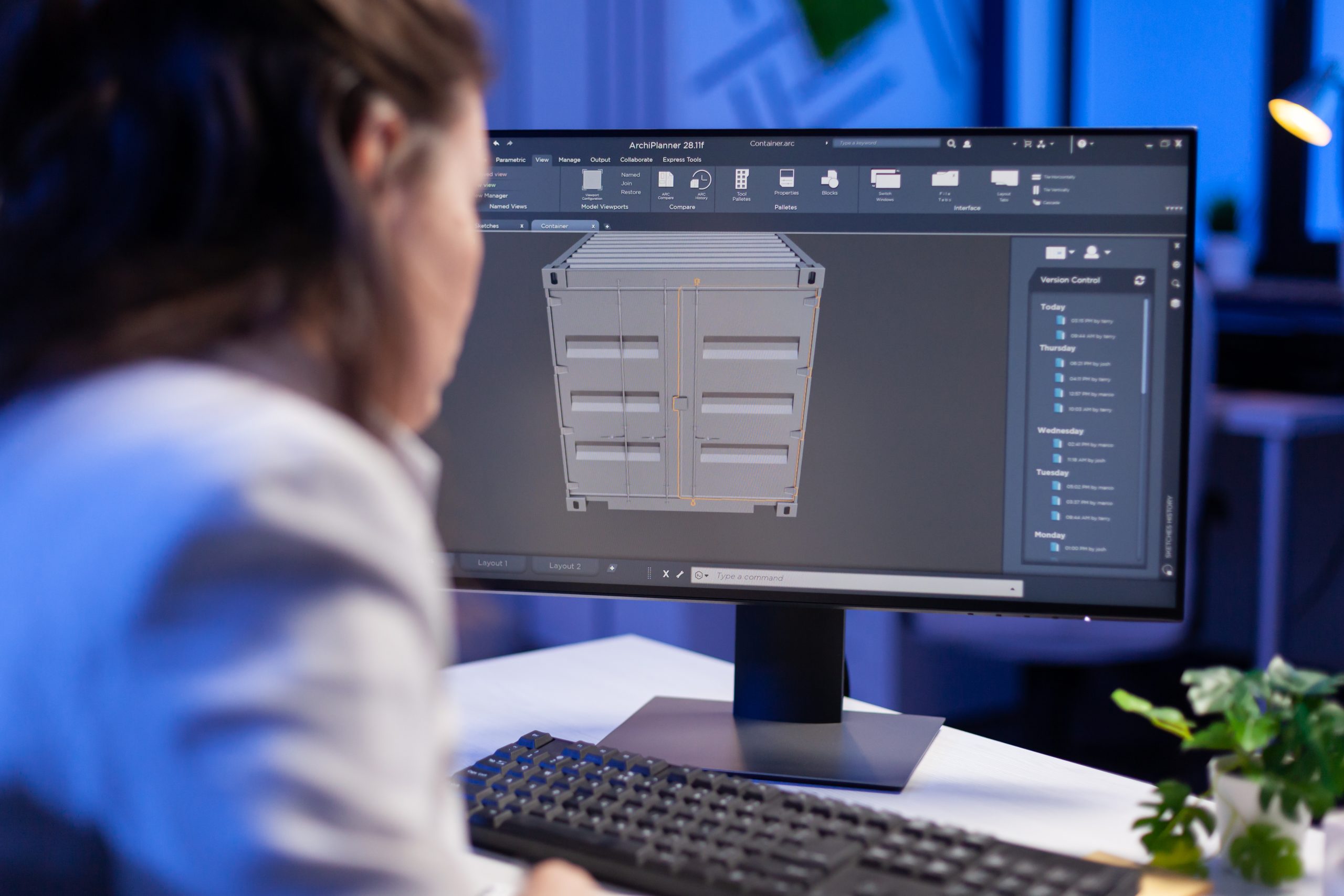

The digital age has brought about a transformation in the plastic injection moulding landscape. Advancements in technology – particularly in computer-aided design (CAD) software and computer-aided manufacturing (CAM) systems – have revolutionised product development and production processes.

CAD facilitates the creation of intricate 3D designs with unparalleled precision, providing manufacturers with a clear blueprint for the final product. CAM systems, on the other hand, translate these designs into machine-readable instructions, streamlining the manufacturing process and ensuring accuracy.

Moreover, automation and robotics have significantly enhanced the efficiency and speed of plastic injection moulding. Automated systems can perform tasks such as material handling, mould loading, part ejection, and quality inspection with precision and speed, reducing the margin of error and increasing overall productivity.

Bosworth Plastics is at the forefront of these technological advancements, continually upgrading our processes to integrate the latest technologies. By doing so, we enhance our capabilities, ensuring faster turnaround times, cost efficiency, and consistently superior products for our clients.

Our commitment to innovation extends to our research and development initiatives. We invest in cutting-edge technologies, collaborate with industry experts, and engage in continuous learning to stay ahead of the curve. By doing so, we ensure that our clients receive products that meet the latest industry standards and exceed their expectations.

Get In Touch!

When it comes to plastic injection mould tooling, Bosworth Plastics is a trusted partner you can count on. Whether you have a small prototype or a large-scale production project, we have the expertise and resources to exceed your expectations.

Contact us today to discuss your project, request a quote, or schedule a consultation with our expert team.

Let us be your partner in moulding success!

If You’re Looking For Top-Quality Injection Mould Toolmakers, Make Sure You Contact Us!

Plastic Injection Moulded Product Specialist