Plastic Injection Moulding Companies

Need A Top-Quality Plastic Injection Moulding Company?

Look No Further Than Bosworth Plastics!

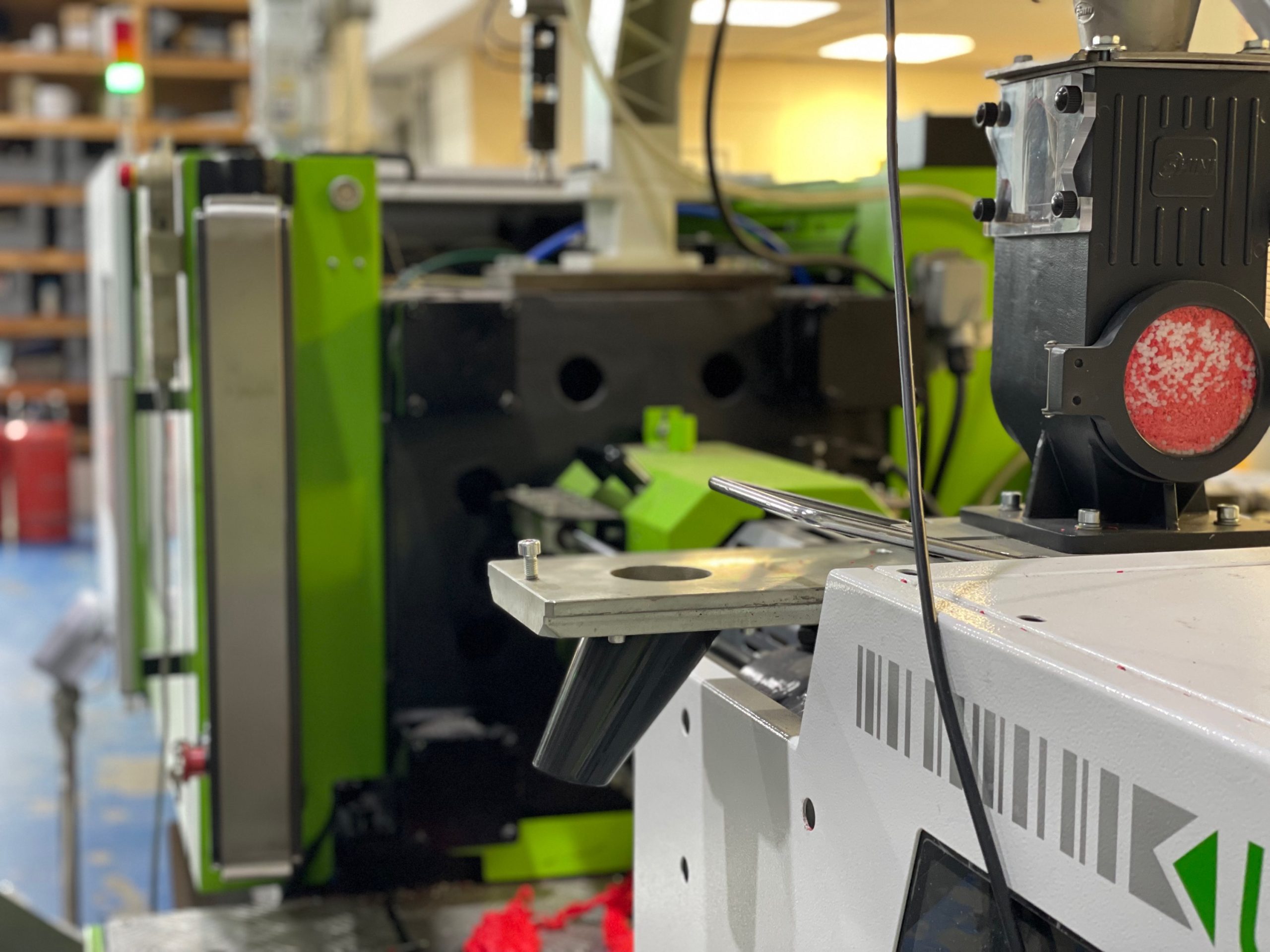

At Bosworth Plastics, we are proud to be an expert plastic injection moulding company trusted by many of the UK’s leading manufacturers. We serve a wide range of blue-chip clients across several industries by delivering tools and components that meet the highest standards of accuracy, consistency, and durability.

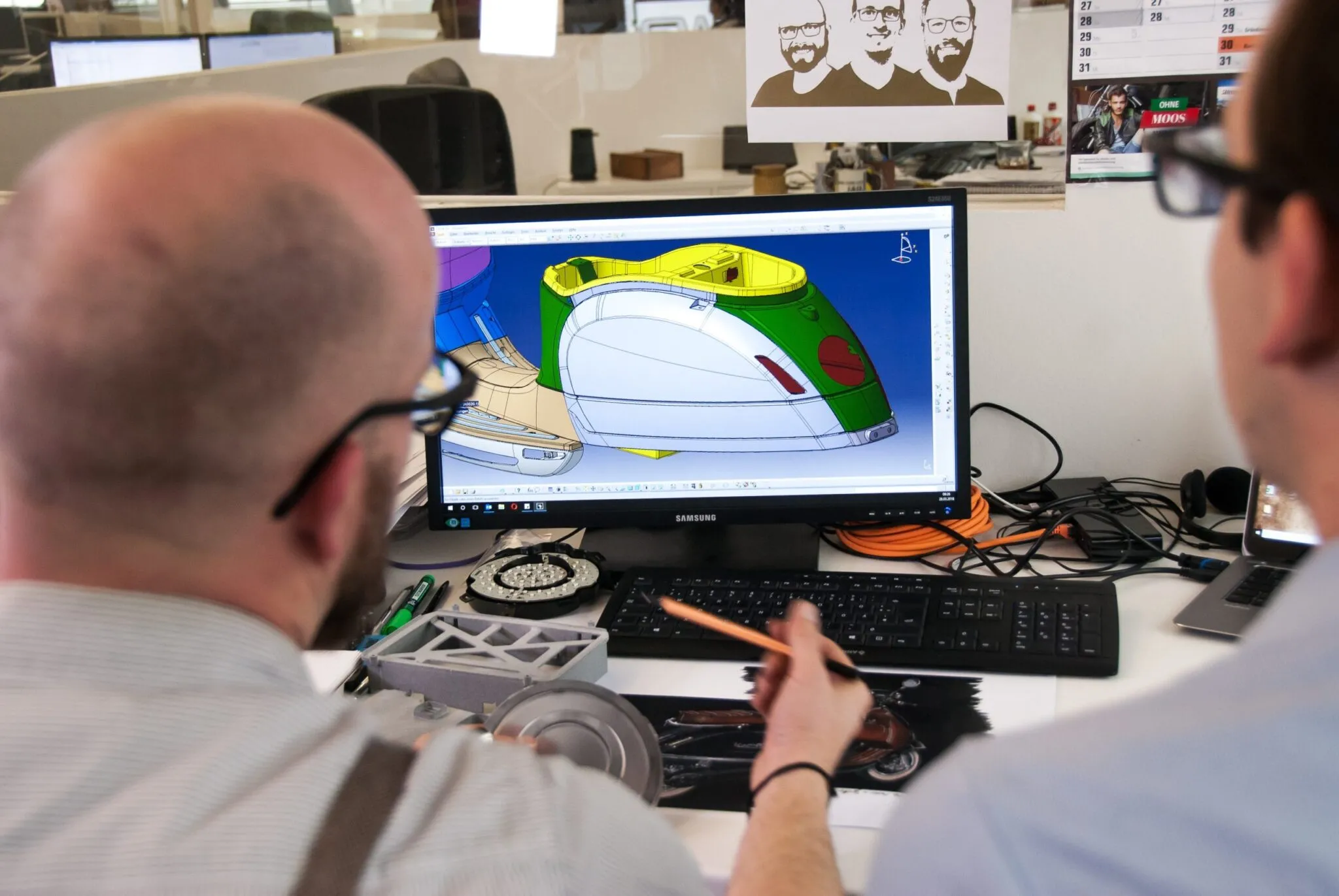

Our reputation is built on three core principles: precision, professionalism, and performance. These values are present in everything we do, from concept design to final tool delivery. With a team of highly skilled engineers and technicians – alongside cutting-edge CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) systems – we bring each client’s vision to life reliably and efficiently.

Operating from our state-of-the-art facility in Leicestershire, UK, we bring together decades of hands-on experience, technical innovation, and industry knowledge. Whether you require a prototype or a fully scaled production tool, Bosworth Plastics is your expert partner in plastic injection moulding!

What Do Plastic Injection Moulding Companies Do?

What Does A Plastic Injection Moulding Company Do?

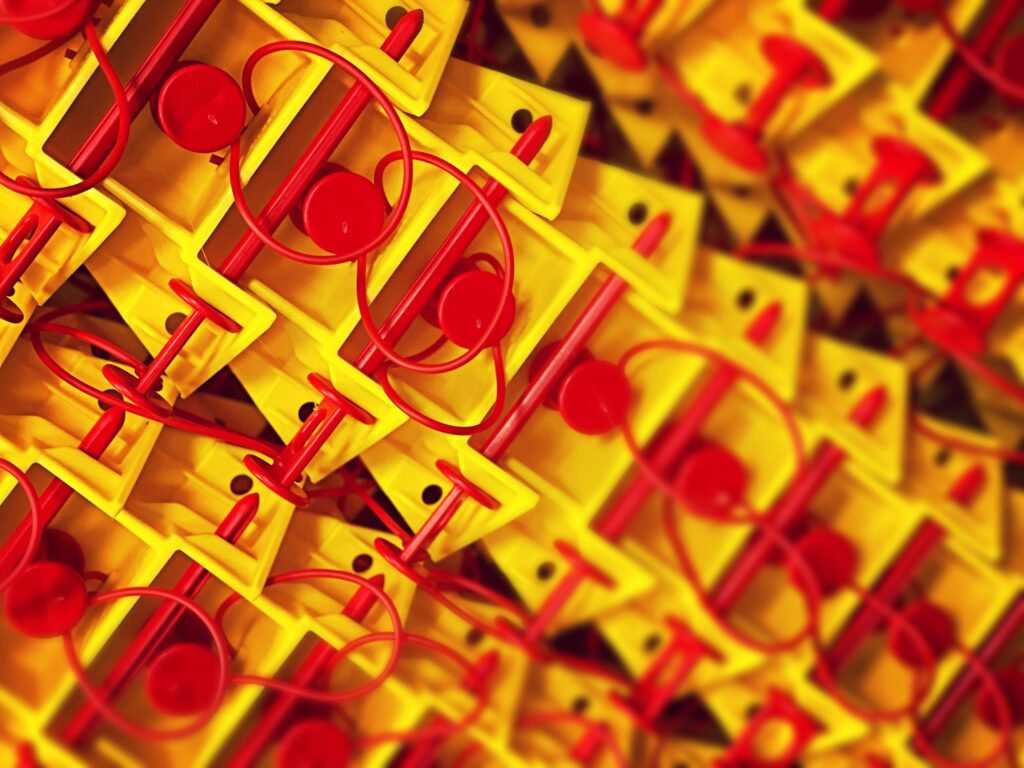

Plastic injection moulding is a widely used manufacturing process for producing precise, high-volume plastic parts. It involves injecting molten plastic into a custom-designed mould, which cools and solidifies into the final component.

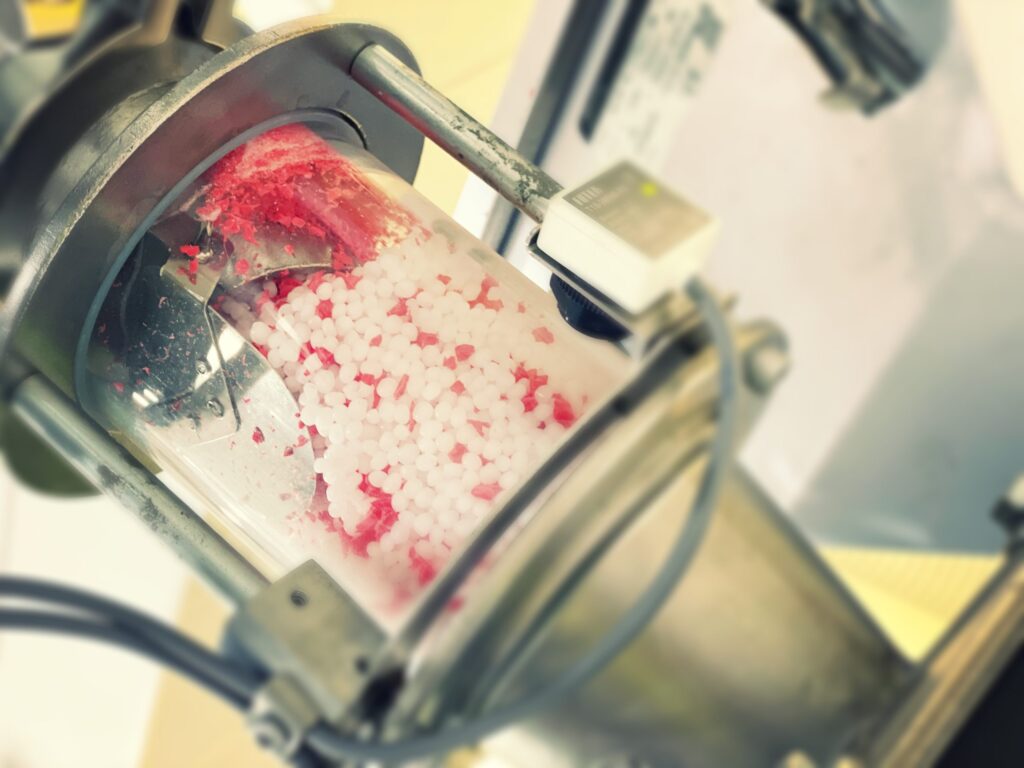

This process begins with the melting of plastic resin pellets. Once liquefied, the material is injected under high pressure into a steel mould cavity. As the plastic cools, it takes the shape of the mould. After solidification, the mould opens, and the finished part is ejected.

This technique is ideal for making complex, high-volume parts efficiently and accurately, being widely used in industries such as automotive, consumer electronics, healthcare, and aerospace.

The Applications Of Plastic Injection Moulding

The versatility of plastic injection moulding has made it a critical manufacturing method across countless sectors. It is used to produce everything from intricate medical components and household items to large automotive panels and industrial parts.

Because the process supports both small and large production runs, it allows manufacturers to bring products to market faster and more cost-effectively than with traditional methods.

At Bosworth Plastics, we bring together deep industry knowledge and technical innovation to deliver tools that support this wide array of applications.

Plastic Injection Moulding: The Future Of The Manufacturing Industry?

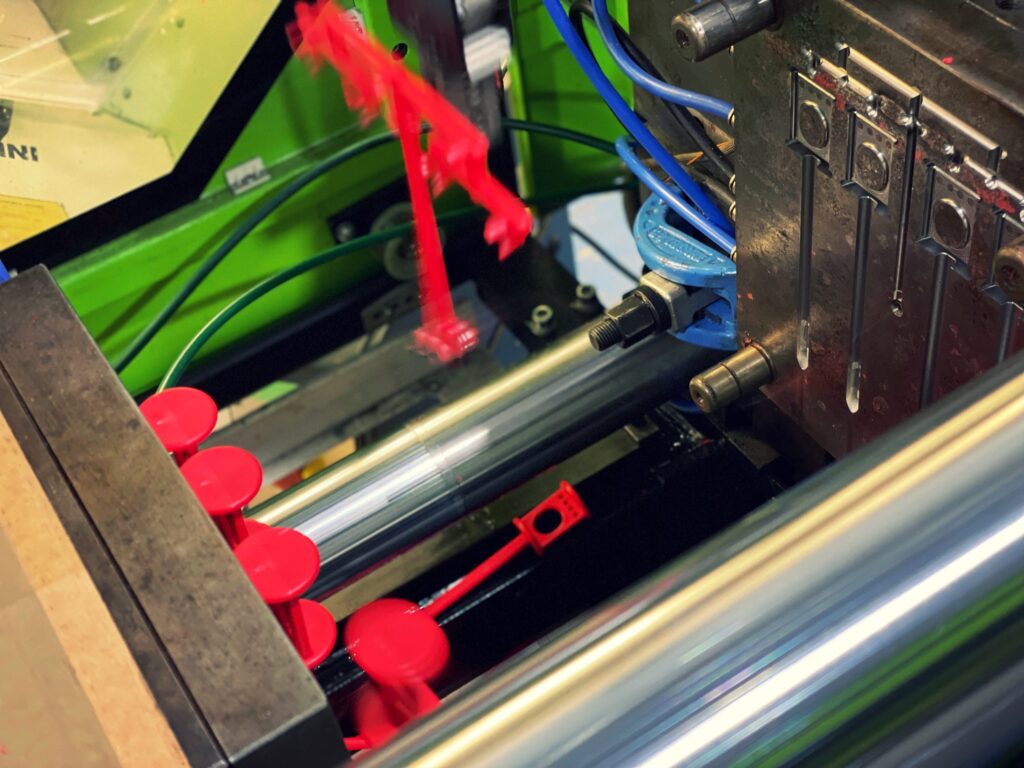

Emerging technologies are reshaping how products are designed and manufactured — and plastic injection moulding is no exception. Advanced systems like CAD and CAM have revolutionised how we design and produce mould tools.

CAD enables engineers to create highly detailed 3D digital models, which can then be directly converted into instructions using CAM software. These instructions guide our automated machinery, ensuring seamless and accurate production.

The integration of robotics and automation into the moulding process has also dramatically improved efficiency. Automated systems perform key tasks such as material loading, part removal, and quality inspection with unmatched speed and precision — reducing human error and increasing productivity.

These technological advancements make plastic injection moulding faster, more reliable, and more scalable than ever, making it central to the future of manufacturing.

Why Choose Us When You Need A Plastic Injection Moulding Company?

Why Choose Us When You Need Plastic Injection Moulding Companies?

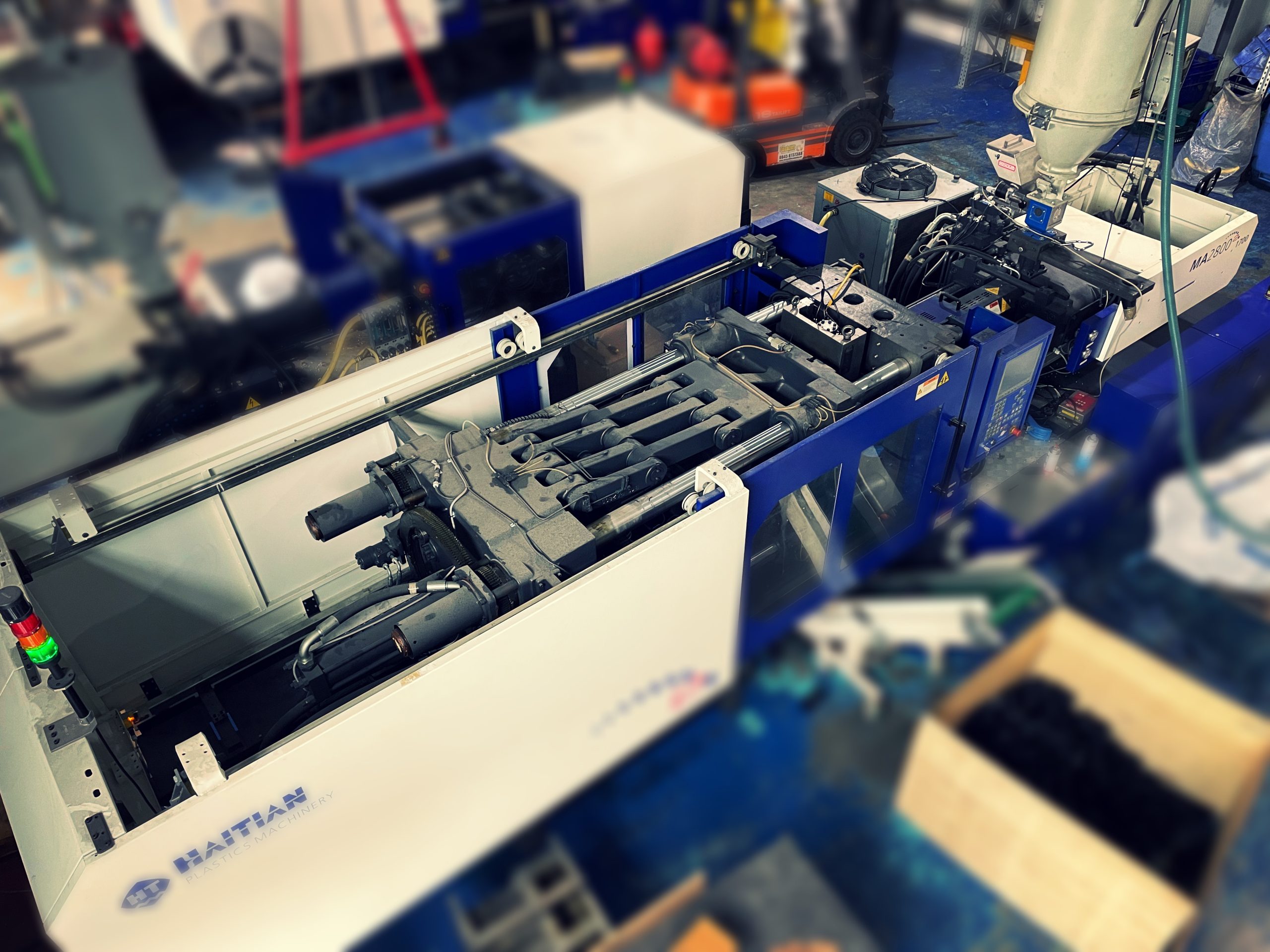

When you choose Bosworth Plastics, you’re partnering with a team of experienced plastic injection moulding specialists, all based at our state-of-the-art facility in Leicestershire, UK. From the first design concept to the final delivery, we’re here to support you every step of the way—giving you complete confidence in the quality of the tooling we create.

We’re proud to offer our clients a wide range of exciting benefits, including:

Innovative Technology

Our investment in advanced technologies enables us to deliver top-quality results across every tooling project. At Bosworth Plastics, we utilise some of the most sophisticated equipment available in the industry.

Our systems are capable of processing a wide variety of materials — from standard commodity plastics to high-performance polymers — ensuring flexibility and adaptability for complex and diverse project requirements.

We are continuously evolving with industry advancements. Our integrated CAD/CAM systems allow us to turn intricate 3D designs into machine-readable instructions, streamlining the transition from design to production and ensuring each tool is manufactured to exact specifications.

In addition to performance, we remain committed to environmental responsibility. Our processes are designed to minimise material waste and reduce our carbon footprint. From energy-efficient machinery to sustainable raw material sourcing, we take proactive steps to support environmental sustainability.

Tailored Services

Every project we undertake is unique, and we treat it as such. At Bosworth Plastics, we don’t believe in one-size-fits-all solutions. Instead, we work closely with each client to develop bespoke services that align with their objectives, timelines, and technical requirements.

We begin by gaining a clear understanding of your project goals. From there, our tooling specialists collaborate with you to develop custom solutions — whether for short-run production, high-volume manufacturing, or prototype development. Our aim is to ensure your finished tool meets not only your functional needs but also your market and quality expectations.

We also place a strong emphasis on communication and transparency. Throughout every stage of the design and manufacturing process, we keep you informed and involved. This collaborative approach helps ensure that the finished tooling is optimised for your intended application and produced to the highest possible standard.

Our end-to-end service offering covers every phase of the process, including concept development, CAD modelling, prototyping, tool fabrication, testing, and support. Post-delivery, we remain available to address any concerns or questions you may have, and are committed to resolving issues quickly and effectively.

Quality Assurance

At Bosworth Plastics, quality is non-negotiable. We follow robust quality control procedures at every stage of the tooling process to ensure our clients receive only the most reliable and consistent results.

We operate under ISO-certified quality management systems, which are integrated into our daily operations. From the initial material selection to final inspection, our team performs rigorous checks to verify that all components meet our clients’ exacting standards.

Every tool that leaves our facility undergoes a thorough validation process to ensure dimensional accuracy, surface finish, and functional reliability. These high standards are why so many of our clients return to us project after project.

When you work with Bosworth Plastics, you’re investing in the reliability and longevity of your production tools — and by extension, in the success of your products!

Cost-Effective Rates

We understand that achieving value for money is essential in today’s competitive manufacturing environment. That’s why Bosworth Plastics offers premium-quality mould tooling services at cost-effective prices.

Our efficient production techniques, lean manufacturing practices, and economies of scale help us keep costs down without sacrificing quality. We pass those savings on to our clients, ensuring that you receive a strong return on investment.

Whether you’re developing a new product or scaling up production, our solutions are designed to be budget-friendly while maintaining excellence in engineering and performance.

Reliable Timekeeping

Time is a critical factor in product development, and delays can impact your entire supply chain. That’s why on-time delivery is one of our top priorities.

At Bosworth Plastics, we follow strict project management protocols to ensure all projects are completed within their agreed timelines. Our streamlined workflows, experienced personnel, and real-time scheduling tools allow us to manage production efficiently and respond quickly to unforeseen changes.

With Bosworth Plastics, you can count on timely delivery without compromising quality — helping you maintain your production schedules and uphold your business reputation.

Contact Us If You Need A Plastic Injection Moulding Company!

When it comes to reliable, high-precision plastic injection mould tooling, Bosworth Plastics is the partner you can count on. Our commitment to technical excellence, exceptional customer service, and sustainable production makes us a leading choice for UK manufacturers.

From initial design and prototyping to full-scale production, we deliver the tools you need to bring your products to life — on time and on budget.

Ready to start your project or have further questions? Contact our expert team today to schedule a consultation and receive a free, no-obligation quote. We look forward to speaking with you.

If You Need Top-Quality Plastic Injection Moulding Companies, Make Sure You Contact Us!

Plastic Injection Moulded Product Specialist