Plastic Mould Tools

Need Top-Quality Plastic Mould Tools?

Look No Further Than Bosworth Plastics!

At Bosworth Plastics, we are proud to be leading providers of plastic mould tools for discerning clients across a wide range of industries.

By consistently integrating the latest advancements in CAD, CAM, and automated technologies into our processes, we ensure that we remain ahead of industry standards; this allows us to offer our clients fast turnaround times, cost-effective solutions, and premium-quality products!

As part of our dedication to innovation, we invest heavily in research and development initiatives. Through collaboration with industry experts and the utilisation of cutting-edge technologies, we foster continuous learning, growth, and improvement. This commitment ensures that we not only meet, but exceed, client expectations by delivering consistently exceptional service and outstanding results.

What Is Plastic Injection Moulding?

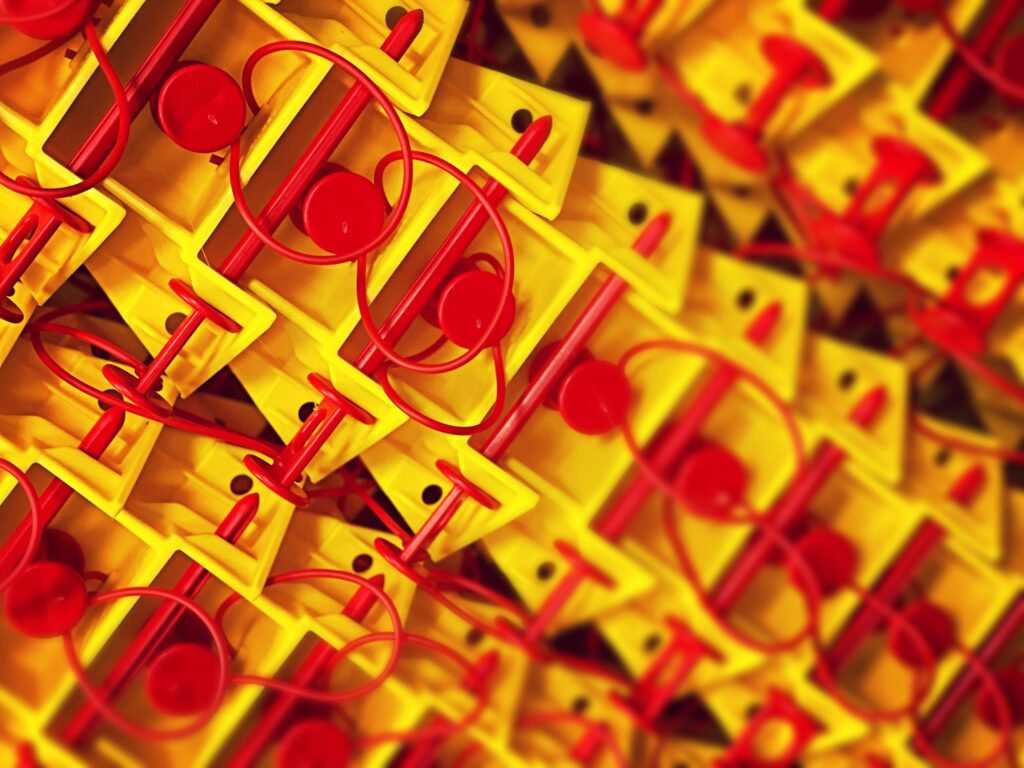

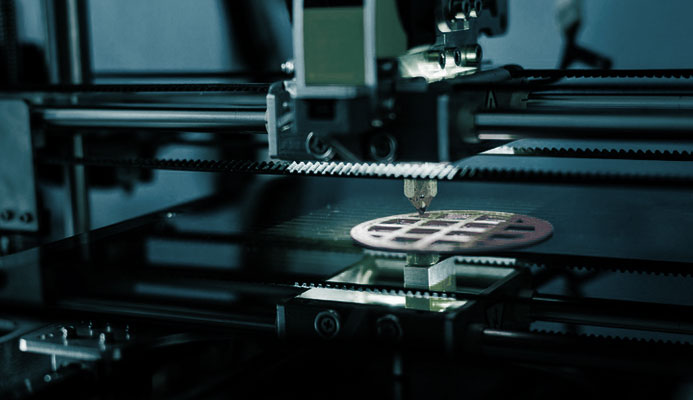

Plastic injection moulding is a sophisticated manufacturing process for creating high-quality plastic parts and products with exact specifications. Using specialised machinery and moulds, it turns raw plastic material into finished, market-ready goods.

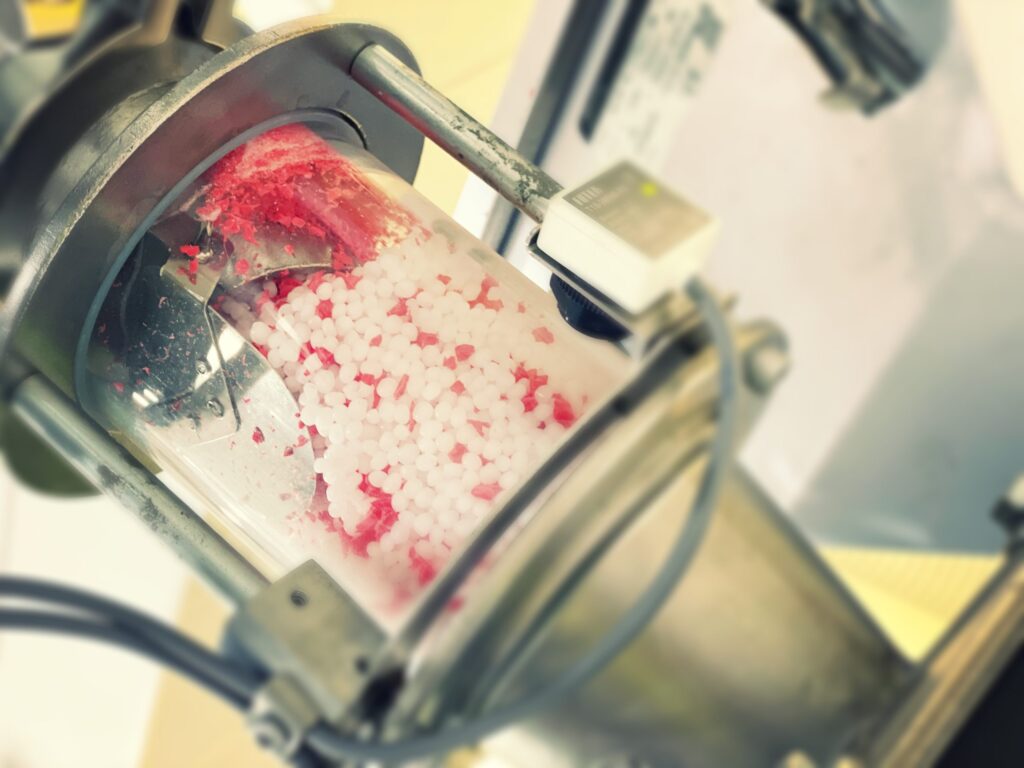

Firstly, plastic pellets are melted down and injected into a pressurised mould cavity. Once inside, the plastic cools and solidifies into the desired shape.

This technique is widely used across various industries to create an array of products, ranging from small components to significantly larger items.

Which Sectors Use Plastic Injection Moulding?

Plastic injection moulding is a versatile process that has become integral to manufacturing across many industries.

It can be used to produce a wide variety of products, from tiny components to large parts, making it a cornerstone in modern manufacturing. Industries that regularly rely on plastic injection moulding include automotive, aerospace, healthcare, consumer goods, and electronics.

At Bosworth Plastics, we take pride in combining advanced technology with expert craftsmanship. We focus on quality control at every step, ensuring our skilled professionals work together to deliver precise and reliable products for our clients, every time.

The Future Of Manufacturing?

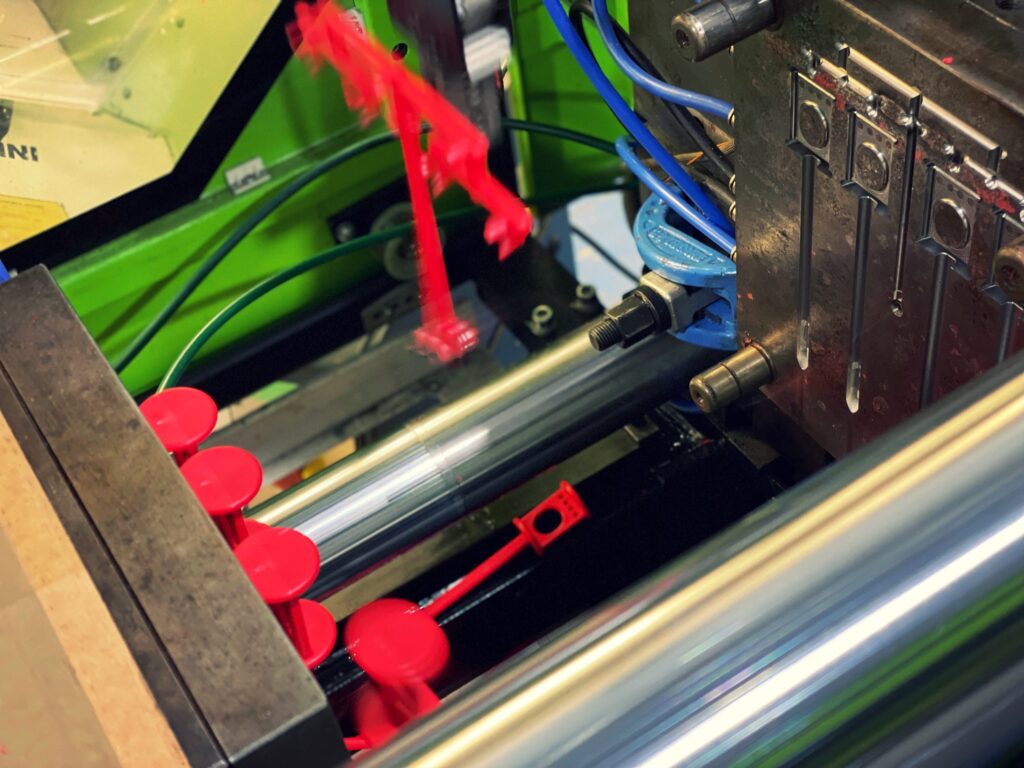

Plastic injection moulding relies on cutting-edge technology to improve product development and manufacturing efficiency. It uses computer-aided design (CAD) and computer-aided manufacturing (CAM), along with automation and robotics, to streamline manufacturing processes.

CAD and CAM play distinct but crucial roles in plastic injection moulding. CAD allows manufacturers to create detailed 3D designs with high precision, providing a clear blueprint for the finished product.

CAM, on the other hand, translates these detailed designs into instructions that manufacturing machinery can understand. This promotes consistent accuracy and precision.

Automation and robotics have also revolutionised plastic injection moulding, making it faster and more reliable. Automated systems can perform tasks that require extreme accuracy and speed, like material handling, mould loading, part ejection, and quality inspection. This increased automation leads to higher productivity and reduces the likelihood of errors.

Why Choose Us For Plastic Mould Tools?

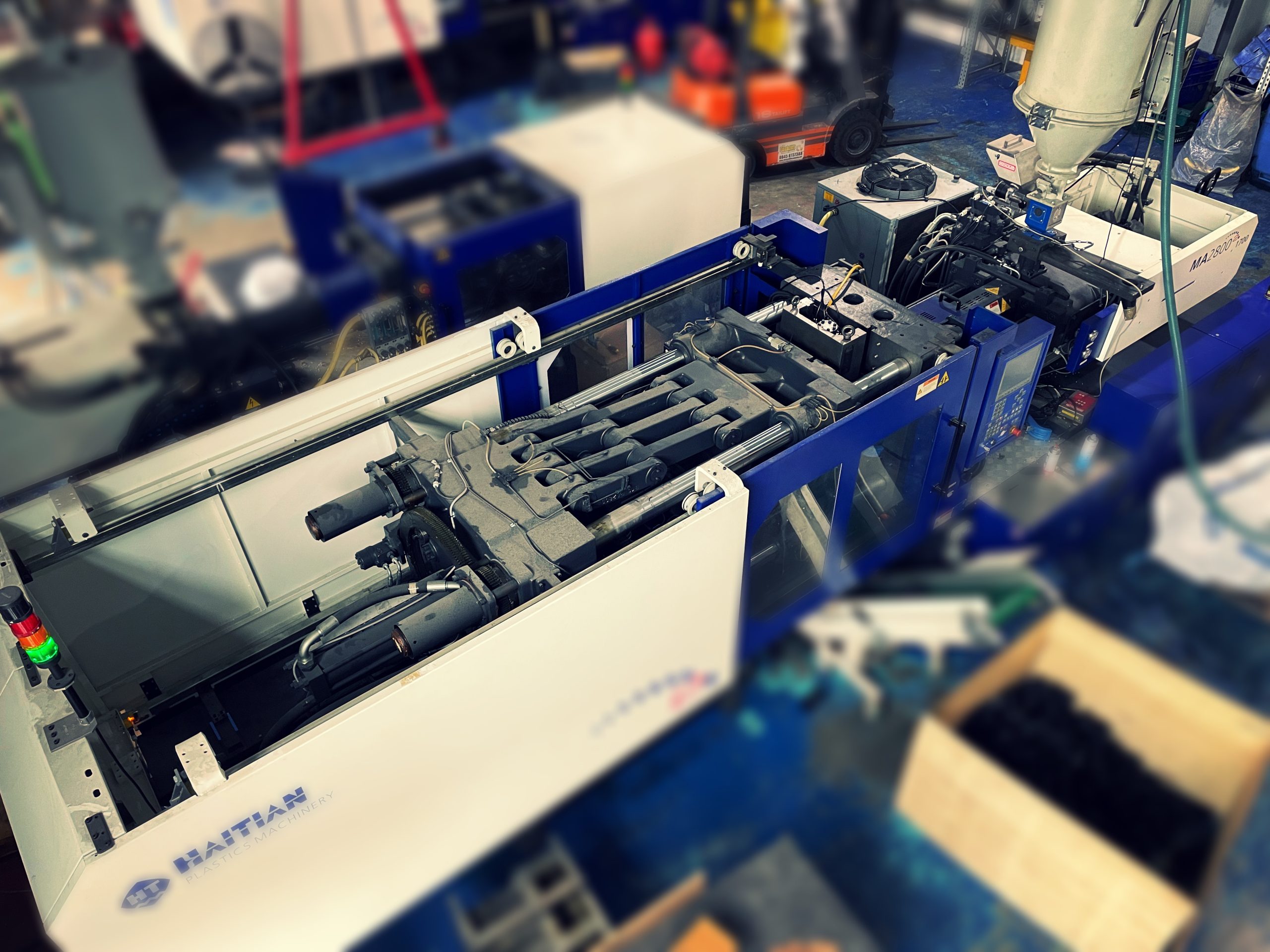

At Bosworth Plastics, we’re proud to offer superior quality plastic injection mould tooling services to the UK’s manufacturing industry. Our commitment to outstanding quality, precision, and professional expertise is at the core of everything we do, ensuring our esteemed clients always get the best quality service.

Our advanced facilities feature the latest in CAD, CAM, and automation technology, all operated by a team of highly skilled plastic injection moulding experts. Choosing Bosworth Plastics means investing in the future of your product design.

Just some of the benefits of choosing us include:

Plastic Injection Moulding Expertise

At Bosworth Plastics, we know that innovation demands deep industry expertise. That’s why our team comprises experienced professionals who bring a wealth of knowledge to every project.

From custom mould tooling to intricate components and high-volume production, our expertise spans a wide range of industries.

Whether you’re in the automotive, aerospace, medical devices, or consumer electronics sector, we can meet all your plastic injection moulding needs!

Cutting Edge Technology

We stay at the forefront of industry standards by using state-of-the-art technology and equipment.

Our machines can work with a variety of raw materials – from basic plastics to high-performance polymers – offering versatility and precision for all your projects.

Moreover, we’re committed to sustainability, striving to minimise waste and reduce environmental impact throughout the manufacturing process.

Custom Solutions

We understand that every project is unique. That’s why we tailor our approach to meet your specific requirements.

Our team of skilled engineers and designers will collaborate closely with you, ensuring that your mould tool aligns with your vision and meets all the necessary quality standards.

Quality Assurance

Quality is our top priority! We use ISO-certified quality management systems to guarantee that every tool meets or exceeds our clients’ expectations.

Our rigorous quality control checks, from material selection to final inspection, ensure that we deliver products you can rely on.

Competitive Pricing

We know that cost is a critical factor. That’s why we offer competitive pricing without compromising on quality.

By streamlining our production processes and leveraging economies of scale, we deliver cost-effective solutions, helping you maximise your return on investment.

On Time, Every Time

Timely delivery is crucial to maintaining your business’s reputation.

With efficient production processes and effective project management, we ensure that your orders are delivered on schedule and in pristine condition.

Customer-Centred Services

At Bosworth Plastics, our clients come first. We value your feedback and are always open to addressing any questions or concerns you may have.

Our dedicated customer support team is here to guide you throughout your journey with us, ensuring you get the most out of our services.

Get In Touch

We are your trusted partner for plastic injection mould tooling services. Whether it’s a small prototype or large-scale production, we have the expertise and resources to meet your needs.

Ready to start your project? Contact us to schedule a consultation and get a free quote. Together, we can bring your ideas to life.

If You’re Looking For Top-Quality Plastic Mould Tools, Make Sure You Contact Us!

Plastic Injection Moulded Product Specialist