Precision Plastic Machining

Need Precision Plastic Machining Services?

Make Sure You Contact Us!

Precision plastic machining has become essential across diverse sectors such as aerospace, medical devices, and automotive, where reliability and accuracy are paramount to achieving market-ready products.

At Bosworth Plastics, we are proud to be a leading provider of precision plastic machining services, offering tailored solutions for industries demanding high-quality, accurate plastic components. Our services harness the latest technological advancements – alongside our team’s extensive manufacturing expertise – to achieve exceptional results.

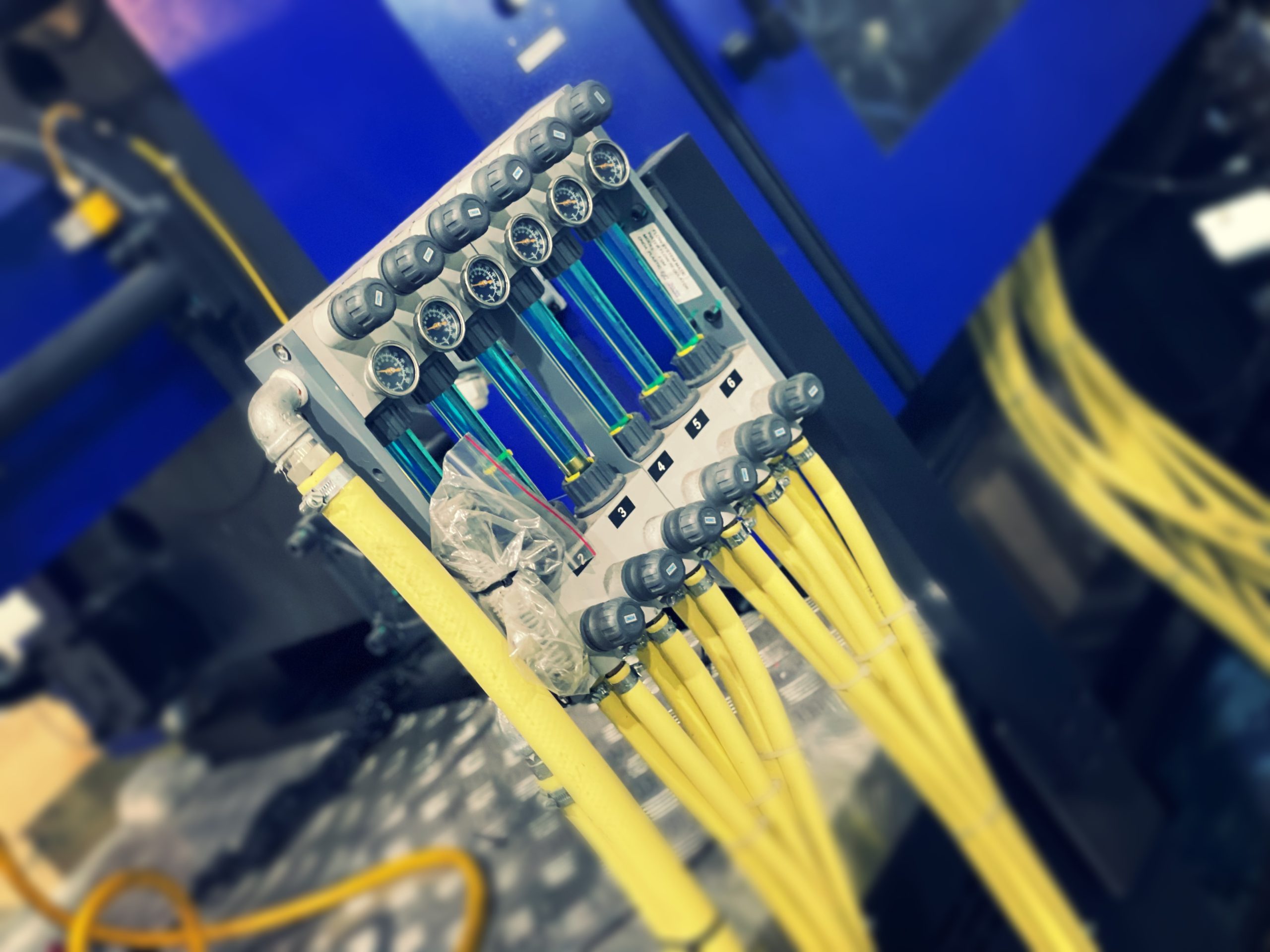

Our Advanced CNC Machining Capabilities

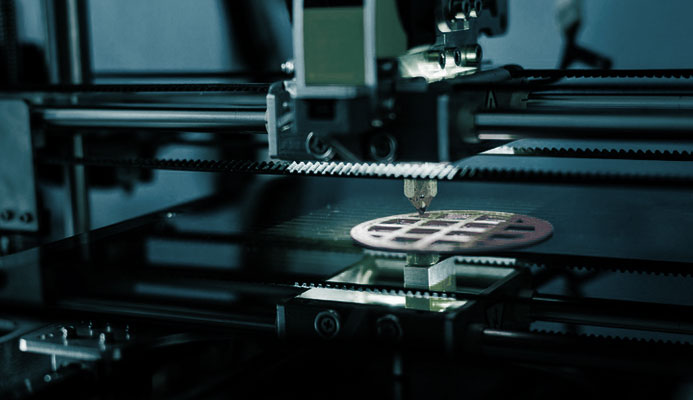

Our services offer clients access to advanced CNC (Computer Numerical Control) machining technology. This process is fundamental for achieving high-precision results, often with tolerances as tight as ±0.005mm.

CNC machining is particularly effective for manufacturing complex geometries and intricate designs that require consistency across production runs. Multi-axis CNC machines are highly versatile, enabling the creation of parts with undercuts, cavities, and other complex features.

Unlike traditional machining, CNC ensures repeatable quality, which is crucial for industries such as medicine, where even minor deviations can compromise functionality. CNC machining also allows for efficient material removal with minimal waste, making it a cost-effective choice for prototypes and small to medium production runs.

Whether you require a single prototype or a large batch of components, at Bosworth Plastics, we ensure high levels of precision at every stage of the manufacturing process.

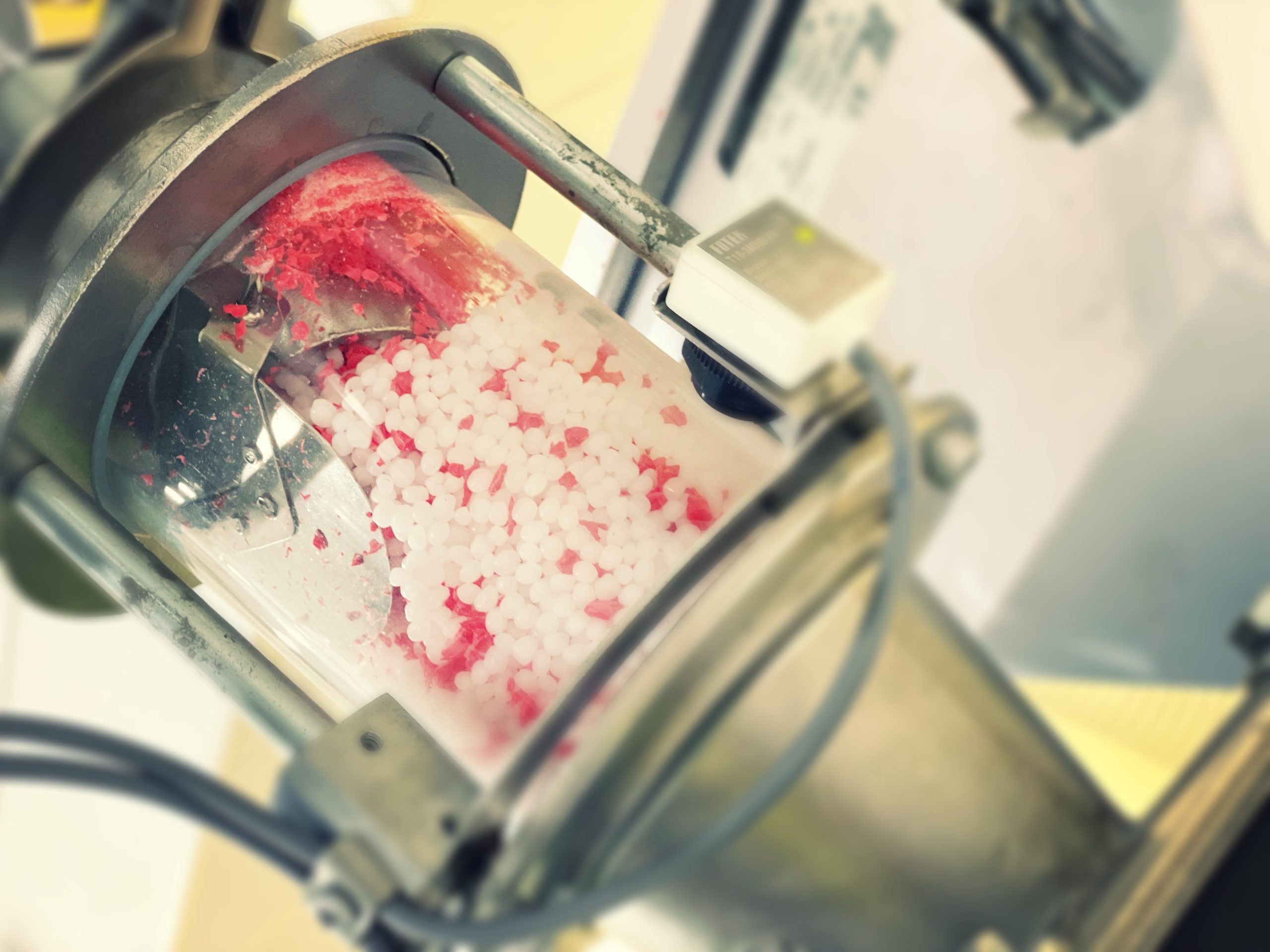

Expertise In Plastic Materials

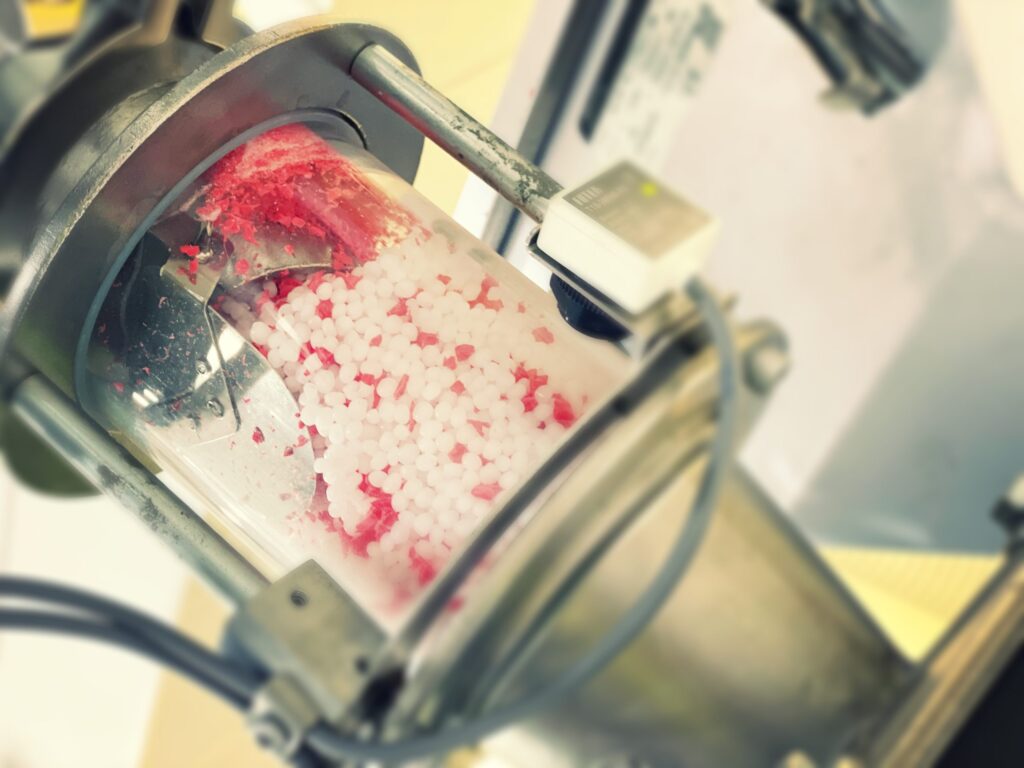

Our team is equipped with extensive expertise in machining a diverse range of plastics. Each material we work with has unique properties for different applications, and understanding these nuances is critical for delivering quality results.

For instance, these are the strengths of some common manufacturing plastics:

Acrylic (PMMA): Renowned for its optical clarity, acrylic is a preferred material for display panels, lenses, and light diffusers. Its machinability allows for smooth finishes, making it an ideal material for aesthetic applications.

Polycarbonate (PC): With high impact resistance and durability, polycarbonate is commonly used in safety equipment and industrial housings.

Delrin (POM): A preferred material for mechanical components like gears and bearings, Delrin offers excellent dimensional stability and low friction.

PTFE (Teflon): Known for its chemical resistance and high-temperature tolerance, PTFE is ideal for seals and components exposed to harsh environments.

Nylon (PA): Nylon’s toughness and flexibility make it suitable for wear-resistant parts such as bushings and fasteners.

At Bosworth Plastics, our team is trained to provide professional guidance on material selection based on the client’s specific project requirements. This ensures the finished components meet all functional and environmental demands.

Customisation And Prototyping

Precision plastic machining is an ideal solution for custom projects, and our team at Bosworth Plastics excels in delivering tailored results. Whether you’re designing a prototype or producing bespoke parts, we work closely with our clients to understand their specific needs.

CNC machining offers rapid prototyping capabilities, enabling designers to quickly iterate and refine their concepts. Unlike 3D printing, which is often limited by material strength, CNC machining delivers prototypes from solid plastics, ensuring durability and functionality. This allows for real-world testing before committing to full-scale production.

Customisation options extend to production runs, where features like intricate threading, tight tolerances, and specific surface finishes can be seamlessly incorporated. At Bosworth Plastics, we ensure that every component, whether a one-off or part of a larger batch, meets the highest precision standards.

The Benefits Of Precision Machining

Superior Surface Finish

Precision machining provides components with smooth, defect-free finishes, often eliminating the need for secondary polishing or treatment. This is particularly valuable for industries like medical devices and consumer goods, where aesthetics are as important as functionality.

Unmatched Accuracy

The computer-controlled nature of CNC machining ensures exceptional accuracy and repeatability. For industries like electronics, where exact dimensions are critical, this precision guarantees performance and reliability.

Cost Efficiency

While methods like injection moulding are more economical for mass production, CNC machining is highly cost-effective for small to medium runs. For instance, it eliminates the need for mould creation, reducing initial expenses for custom or low-volume projects.

Material Efficiency

CNC machining optimises material usage, cutting away only what’s necessary and minimising waste. This is especially advantageous when working with high-cost engineering plastics.

The Applications Across Industries

Bosworth Plastics serves a wide range of industries, offering solutions tailored to unique challenges.

Here is just some of the work we do in various industries:

- Medical Devices: Producing medically safe, high-precision components such as surgical tools, diagnostic equipment, and implantable devices.

- Aerospace: Delivering lightweight, durable parts like brackets, panels, and housings that meet strict regulatory requirements.

- Automotive: Machining components for prototyping and end-use, such as dashboard elements, reservoirs, and connectors.

- Industrial Equipment: Crafting wear-resistant parts like seals, bushings, and machine guards for harsh operating environments.

Quality Assurance And Compliance

We prioritise quality at every step, adhering to ISO-certified processes and industry best practices. Our commitment to precision is reinforced by rigorous quality control measures, including detailed inspections and advanced software for design validation.

Plus, our integration of CAD (Computer-Aided Design) software with CNC machining ensures seamless transitions from design to production. This capability minimises errors and guarantees that components meet exact specifications.

At Bosworth Plastics, we also prioritise sustainability, employing practices that reduce waste and energy consumption.

Comparing Precision Machining To Other Methods

Precision machining offers distinct advantages over alternative manufacturing techniques. Here are the details:

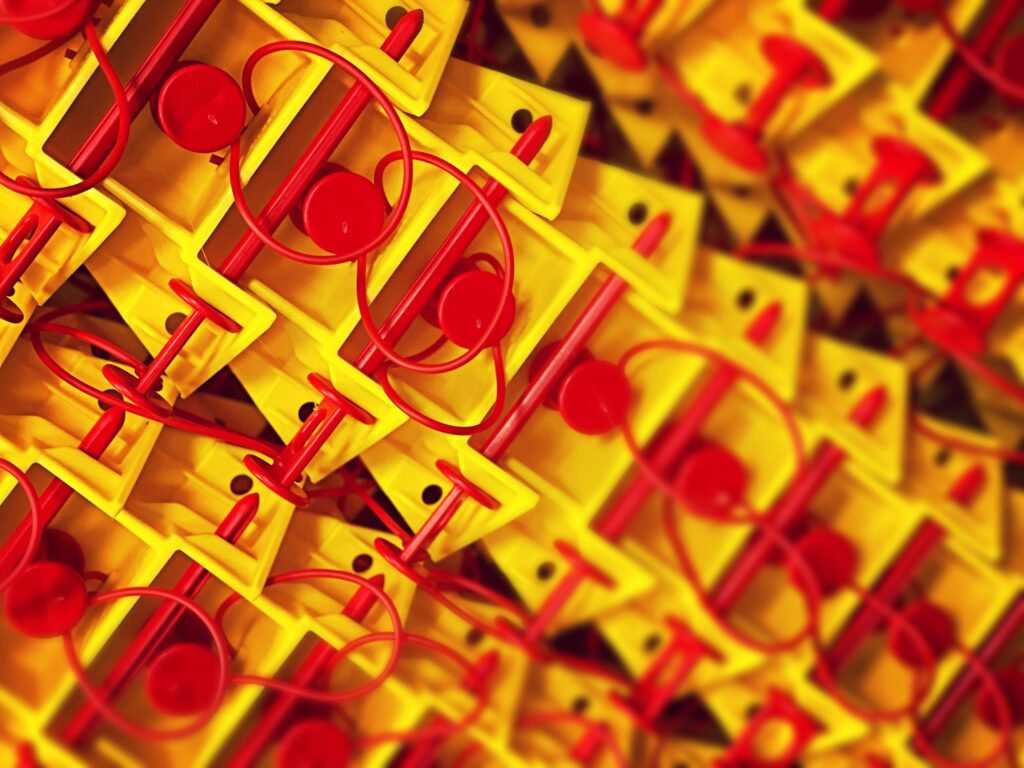

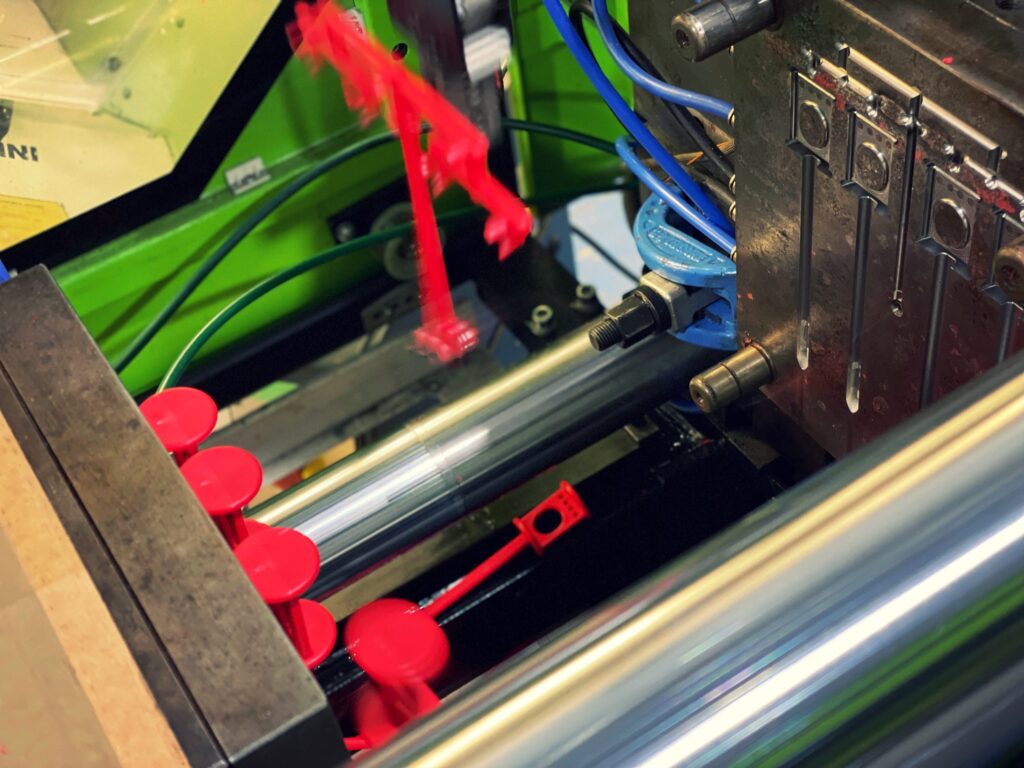

Injection Moulding: While injection moulding is ideal for large-scale production, it requires significant upfront investment in moulds. CNC machining, on the other hand, is more flexible and cost-effective for low to medium volumes.

3D Printing: Though excellent for rapid prototyping, 3D printing often lacks the material strength and surface finish achievable through CNC machining.

Manual Machining: Manual processes cannot match the accuracy and repeatability of computer-controlled systems. CNC machining ensures consistent quality across batches, regardless of complexity.

Why Choose Bosworth Plastics For Precision Plastic Machining?

Comprehensive Expertise: Our team’s experience handling a diverse range of materials and machining techniques ensures optimal solutions for every project.

Customised Solutions: All our services are tailored to meet the unique needs of each client, and we work closely with each client to fully understand their requirements.

Speed And Efficiency: Advanced CNC technology enables quick turnarounds, enabling us to meet tight deadlines without compromising quality.

Sustainability: We are committed to reducing waste and conserving resources in accordance with environmental standards.

Proven Track Record: Our proven history of successful projects across a range of industries has established us as a reliable partner of plastic machining services.

We Are Trusted Providers Of Plastic Machining Services

At Bosworth Plastics, our industry-leading precision plastic machining services are a result of our dedication to quality, innovation, and customer satisfaction.

By combining state-of-the-art technology with material expertise and tailored solutions, we deliver products that meet the highest standards of accuracy and performance.

Whether you’re developing a prototype, refining a design, or scaling up production, we’re equipped with the expertise and resources to bring your vision to life!

Contact Us If You Need Precision Plastic Machining Services!

Plastic Injection Moulded Product Specialist