In the ever-evolving world of manufacturing and product design, Computer-Aided Design (CAD) has become an indispensable tool. At Bosworth Plastics, we have embraced CAD technology to revolutionise our design processes, improve efficiency, and deliver superior products to our clients. This blog post delves into the evolution of CAD development at Bosworth Plastics and how it has transformed our operations.

The Role of CAD in Modern Manufacturing

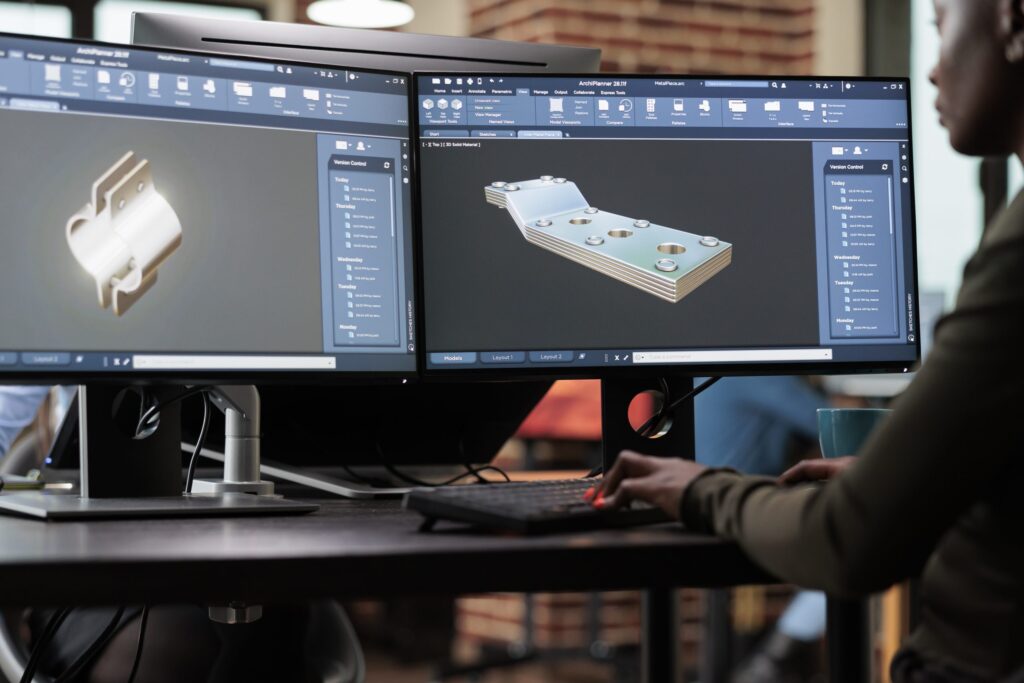

CAD software allows designers and engineers to create precise, 3D models of products and components. These models can be easily modified, tested, and optimised before any physical prototype is made. This not only saves time and resources but also enhances the accuracy and quality of the final product.

Early Adoption of CAD at Bosworth Plastics

Bosworth Plastics recognised the potential of CAD technology early on and invested in its integration into our design processes. Initially, CAD was used for basic drafting and 2D design tasks. However, as the technology advanced, so did our capabilities. Our team underwent extensive training to harness the full potential of CAD software, enabling us to take on more complex projects and deliver innovative solutions to our clients.

Advancements in CAD Software

The CAD software we use today is a far cry from the early versions. Modern CAD tools offer a wide range of features, including:

- 3D Modeling: Allows for the creation of detailed, three-dimensional representations of products.

- Simulation and Analysis: Enables virtual testing of designs for strength, durability, and performance under various conditions.

- Parametric Design: Facilitates the creation of models that can be easily adjusted by changing parameters, making it easier to iterate on designs.

- Collaboration Tools: Supports real-time collaboration among team members, even if they are in different locations.

CAD and Product Development at Bosworth Plastics

The integration of advanced CAD tools into our product development process has had a profound impact on our operations. Here are some of the key benefits we’ve experienced:

Improved Design Accuracy

With CAD, our designers can create highly detailed and accurate models of products. This precision reduces the likelihood of errors during the manufacturing process, leading to higher-quality end products.

Enhanced Collaboration

CAD software’s collaboration features have streamlined communication among our design team, engineers, and clients. This ensures that everyone is on the same page throughout the development process, reducing misunderstandings and speeding up project timelines.

Faster Prototyping and Iteration

The ability to quickly create and modify 3D models allows us to iterate on designs much faster than before. We can test different versions of a product, make necessary adjustments, and move on to prototyping more quickly, reducing time to market.

Cost Savings

By identifying and addressing potential design issues in the virtual environment, we can avoid costly mistakes and rework during the manufacturing phase. This not only saves time but also reduces material waste and overall production costs.

Customisation and Innovation

CAD technology has empowered us to offer more customised solutions to our clients. We can easily tailor designs to meet specific requirements, whether it’s for a unique component or a complete product. This flexibility has allowed us to stay ahead of the competition and continuously innovate.

Looking Ahead: The Future of CAD at Bosworth Plastics

As CAD technology continues to evolve, so will our capabilities at Bosworth Plastics. We are committed to staying at the forefront of these advancements, continuously upgrading our software and training our team. This commitment ensures that we can continue to deliver cutting-edge solutions and exceed our clients’ expectations.

In the near future, we anticipate integrating more advanced simulation tools, incorporating generative design principles, and leveraging artificial intelligence to further enhance our design processes. These advancements will enable us to tackle even more complex projects and maintain our position as a leader in the plastics manufacturing industry.

Conclusion

The adoption and evolution of CAD technology at Bosworth Plastics have been transformative. From improving design accuracy and collaboration to reducing costs and fostering innovation, CAD has become an integral part of our success. As we look to the future, we are excited about the possibilities that further advancements in CAD will bring, and we remain committed to leveraging these technologies to deliver exceptional products and services to our clients.

Stay tuned for more updates on our journey with CAD and how it continues to shape the future of Bosworth Plastics.