Tooling For Plastic Injection Molding

Need Top-Quality Tooling For Plastic Injection Molding?

Look No Further Than Bosworth Plastics!

At Bosworth Plastics, we are a leading provider of tooling for plastic injection molding for manufacturing companies throughout the UK and beyond. We continuously update our processes using the latest advancements in CAD, CAM, and automated technologies, allowing us to stay ahead of the curve. As a result, we can deliver quick turnaround timescales, cost efficiency, and premium-quality products to our valued clientele!

As part of our commitment to innovation, we undertake extensive research and development initiatives. We harness cutting-edge technologies while collaborating with industry experts to achieve continuous learning, growth, and development across the board.

This ensures that our clients receive the standard of service and prestigious results that not only meet – but exceed – their expectations.

What Is Plastic Injection Molding?

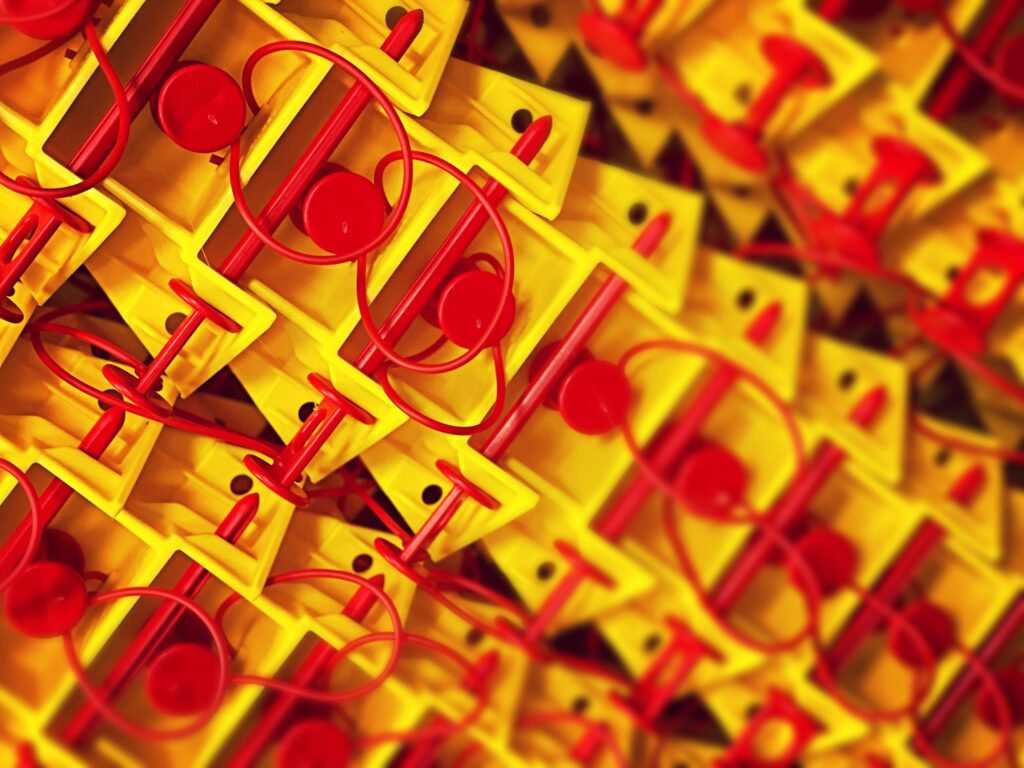

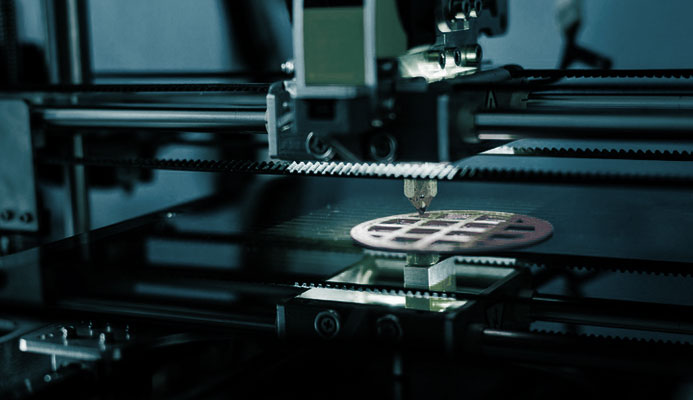

Plastic injection molding is an advanced manufacturing technique, used to create high-quality plastic parts and products to precise specifications. This process uses specialised machinery and molds to fashion fully finished, market-ready products out of raw plastic material.

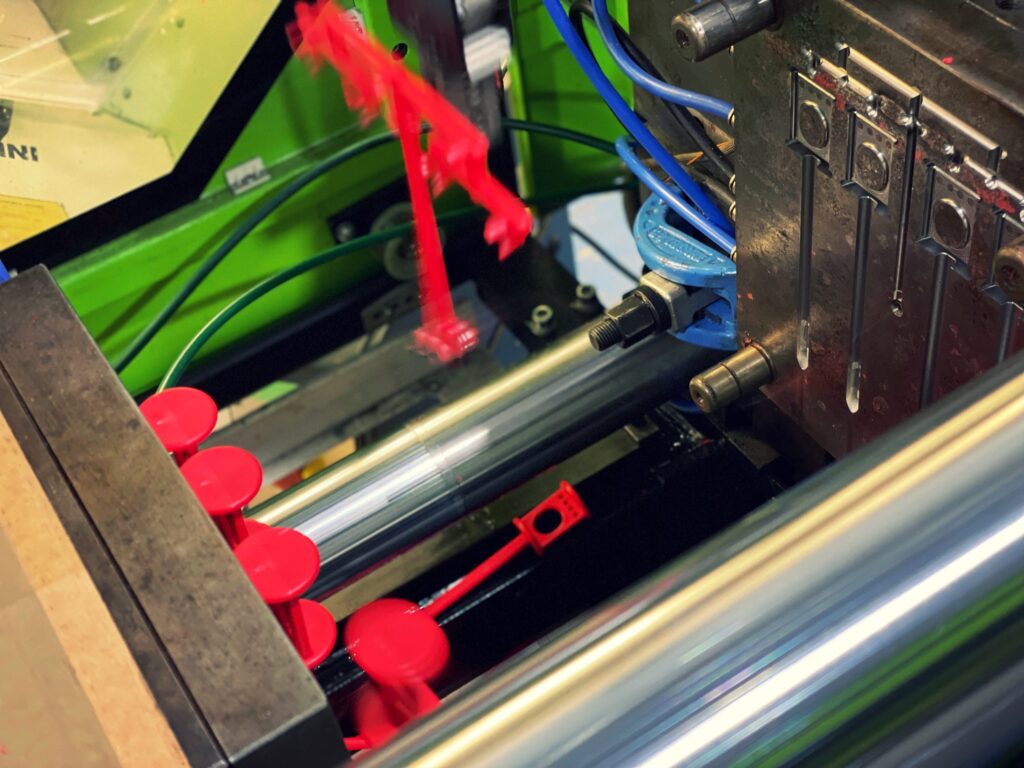

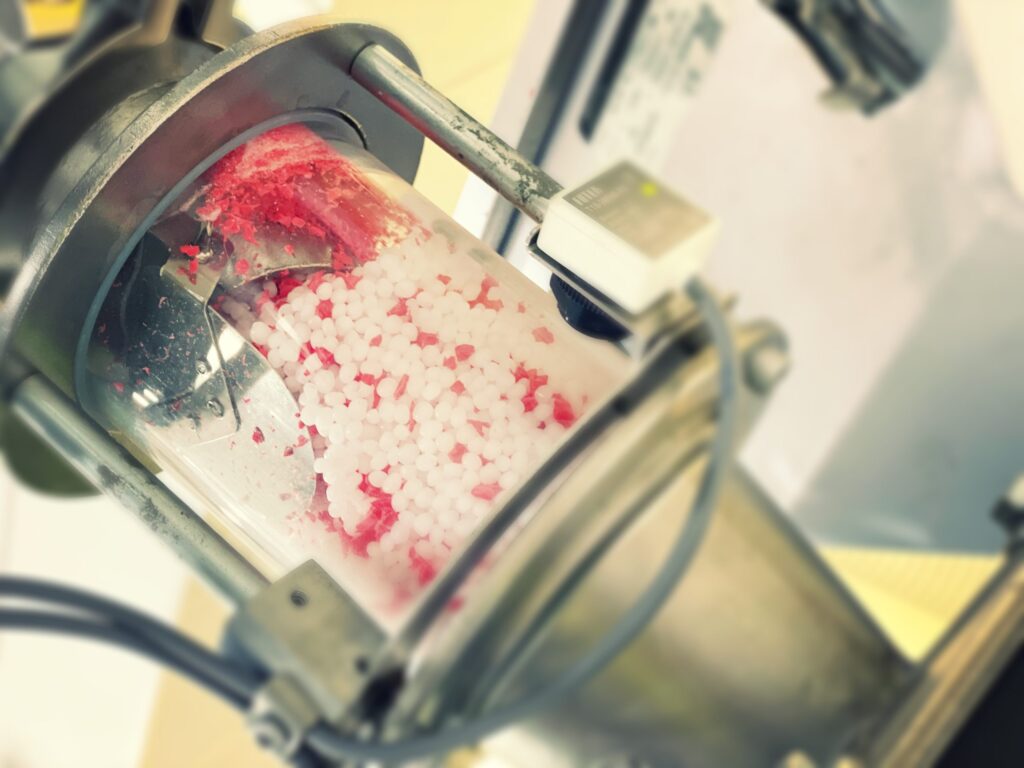

So how does it work? First, the plastic pellets are melted, and injected into a pressurised mold cavity. The plastic cools and hardens within the mold, forming the specified shape.

This method is used by numerous, diverse industries for a wide range of applications and product types.

Which Sectors Use Plastic Injection Molding?

As a direct result of its applicability to a wide range of sectors, plastic injection molding is used in the development of virtually any product on the modern marketplace.

Plastic injection molding can produce both small and large parts, making it an essential process in the manufacturing sector. Industries which use plastic injection molding processes routinely in their operations include automotive, aerospace, healthcare, consumer goods, and electronics.

At Bosworth Plastics, we harness cutting-edge technology and superior craftsmanship in our manufacturing processes. We prioritise quality control throughout our operations, with our skilled professionals working collaboratively to ensure quality and precision in our finished products.

This commitment to technological advancement ensures versatility and precision in every project we undertake. Additionally, our dedication to sustainability is evident as we actively work towards minimising waste and reducing environmental impact throughout our processes.

The Future Of Manufacturing?

Plastic injection molding uses the latest developments in technology, including computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, automation, and robotics, for enhanced product development and production.

CAD and CAM systems play two different, yet equally important roles in the plastic injection molding process. CAD technology is used to create detailed 3D designs, working to high levels of precision. This provides manufacturers with an accurate and clearly defined blueprint for the final product.

CAM systems then formulate these designs into machine-readable instructions. This simplifies the manufacturing process and promotes standards of accuracy and precision.

Plastic injection molding has become faster and more efficient due to the contributions of automation and robotics. Automated systems are capable of handling tasks that require exceptional accuracy and speed, including material handling, mold loading, part ejection, and quality inspection. This improves productivity while reducing the margin of error.

Why Choose Us For Tooling For Plastic Injection Molding?

At Bosworth Plastics, we are proud to provide industry-leading plastic injection mold tooling services for the UK’s manufacturing sector. We are committed to delivering exceptional quality standards, precision, and professional expertise for our prestigious clientele.

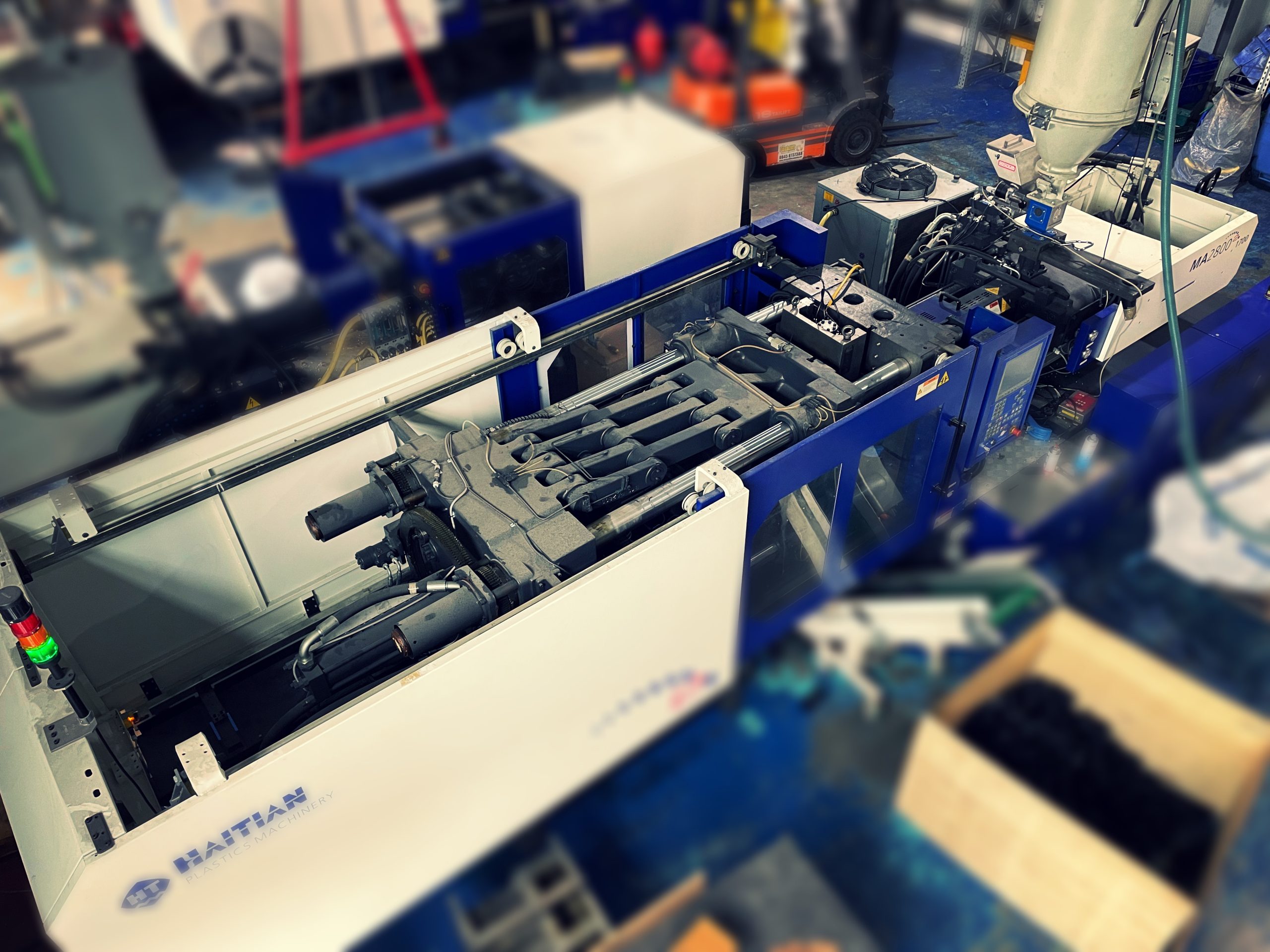

Our state-of-the-art facilities are equipped with cutting-edge CAD, CAM, and automated technologies, and are run by a highly trained and experienced team of plastic injection molding specialists. When you choose Bosworth Plastics, you invest in the future of your product design.

Our services offer a wide range of benefits to our clients, including:

Plastic Injection Molding Expertise

At Bosworth Plastics, we understand that innovation requires a wealth of industry expertise. That’s why our operations are informed by the knowledge and experience of our team of industry experts.

From custom mold tooling to intricate components or high-volume production, we are equipped with the expertise to deliver high-quality results.

With our extensive experience in a wide range of industries, from automotive and aerospace, to medical devices and consumer electronics, we can meet all your plastic injection mold tooling needs to an exceptional standard!

Cutting Edge Technology

We ensure that we meet even the most rigorous of industry standards, harnessing state-of-the-art technology and equipment.

Our machines can fashion tooling using a wide range of raw materials, from commodity plastics to high-performance polymers, for superior versatility and precision in all your projects.

We are committed to sustainability principles and minimise our environmental impact throughout the manufacturing process.

Custom Solutions

At Bosworth Plastics, we understand that every project is different. We adopt a tailored approach to each of our projects, offering custom solutions according to your needs and specifications.

Our team of experienced engineers and designers will work collaboratively with you, using a customer-centred approach to ensure that your mold tool aligns with your vision, and meets quality standards.

We offer a comprehensive solution to your mold tooling needs, from prototyping to production, and exceptional customer support throughout the process.

Quality Assurance

We hold quality assurance paramount throughout our manufacturing processes, using ISO-certified quality management systems to ensure that every tool we produce measures up to our clients’ standards.

We demonstrate our dedication to quality through rigorous quality control checks throughout our production process – from material selection to final inspection. You can trust us to deliver superior quality products that withstand the test of time!

Competitive Pricing

At Bosworth Plastics, we understand that cost-effectiveness is essential for developing high-quality products at a marketable price.

That’s why we offer our customers all the benefits of premium-quality production at reasonable rates.

We deliver cost-effective solutions using efficient production processes and economies of scale, so you can maximise your ROI while maintaining the quality of your products!

On Time, Every Time

We understand that staying on schedule is essential for achieving and maintaining a professional reputation for your business.

That’s why we use streamlined production processes, alongside rigorous project management, to ensure that your orders are always with you on time.

When you choose Bosworth Plastics, you invest in a punctual service that delivers your products in pristine conditions.

Customer-Centred Services

At Bosworth Plastics, we put our clients first. We are proud to work collaboratively with our clients, and we’re open to any feedback or concerns you may have regarding your product development.

Our customer support team is here to assist you throughout your journey with us, to help you get the very best from our services.

Get In Touch!

At Bosworth Plastics, we are your trusted partner for plastic injection mold tooling services. From small prototypes to large-scale production, we are fully equipped to handle your production needs, using our expertise and extensive resources.

Want to discuss your project? Schedule a consultation with our expert team today for your free quote and start your journey with us!

If You’re Looking For Top-Quality Tooling For Plastic Injection Molding, Make Sure You Contact Us!

Plastic Injection Moulded Product Specialist